Die for producing very wide, flat, plastic-based structures

A plastic-based, mold-based technology, used in the field of forming a three-dimensional plastic-based structure and equipment including the mold, and the mold field for preparing a thermoplastic polymer-based structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

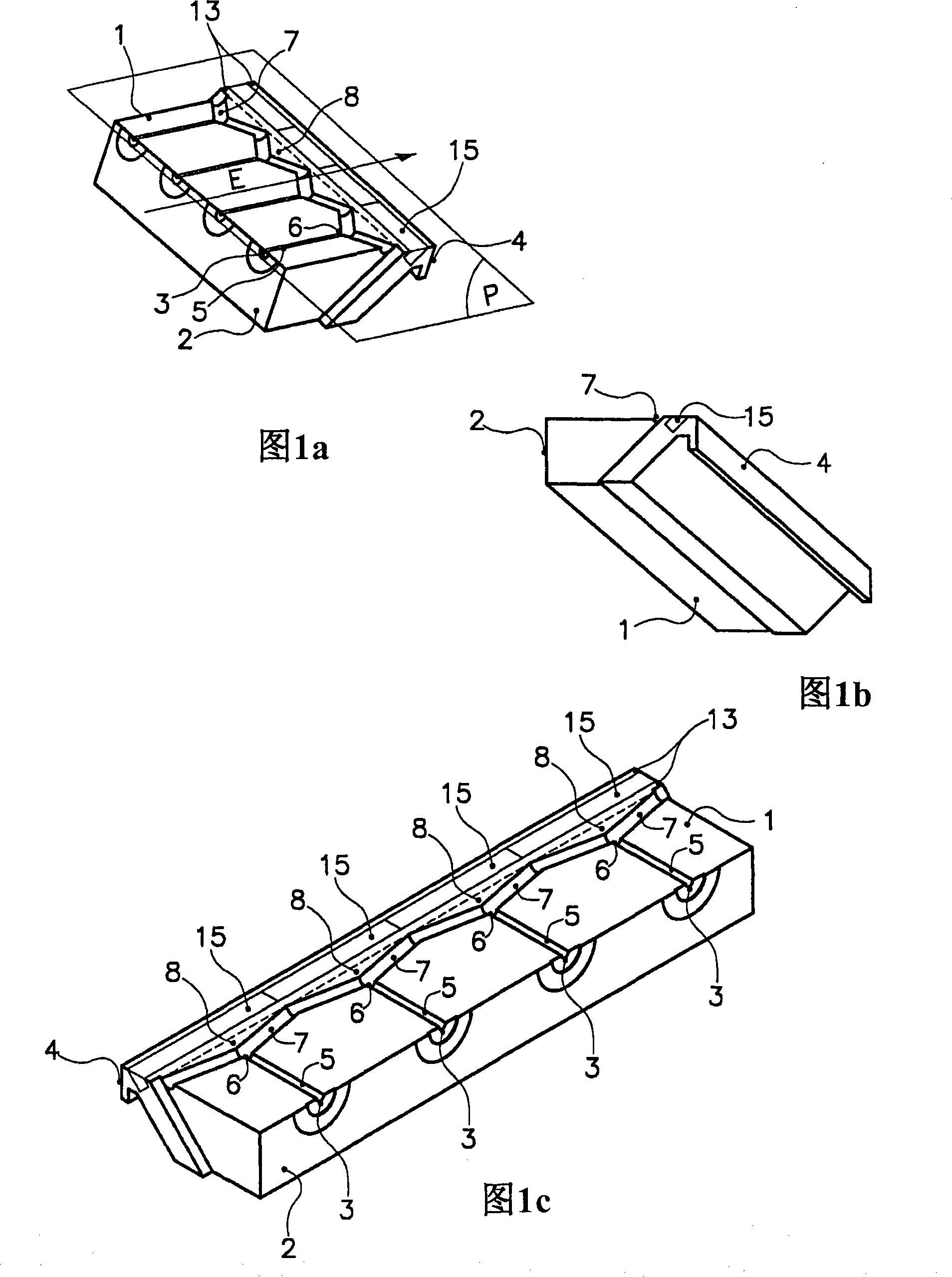

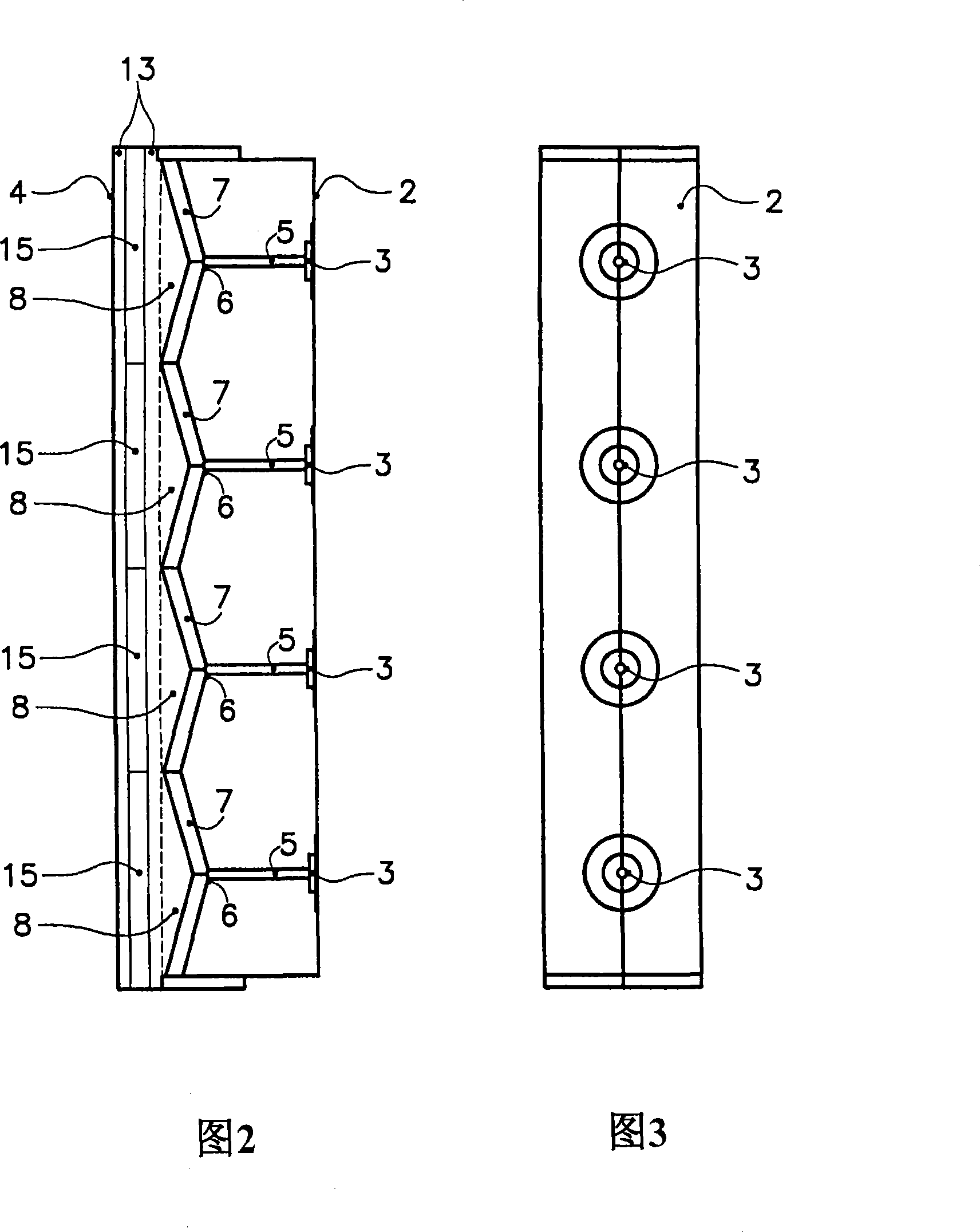

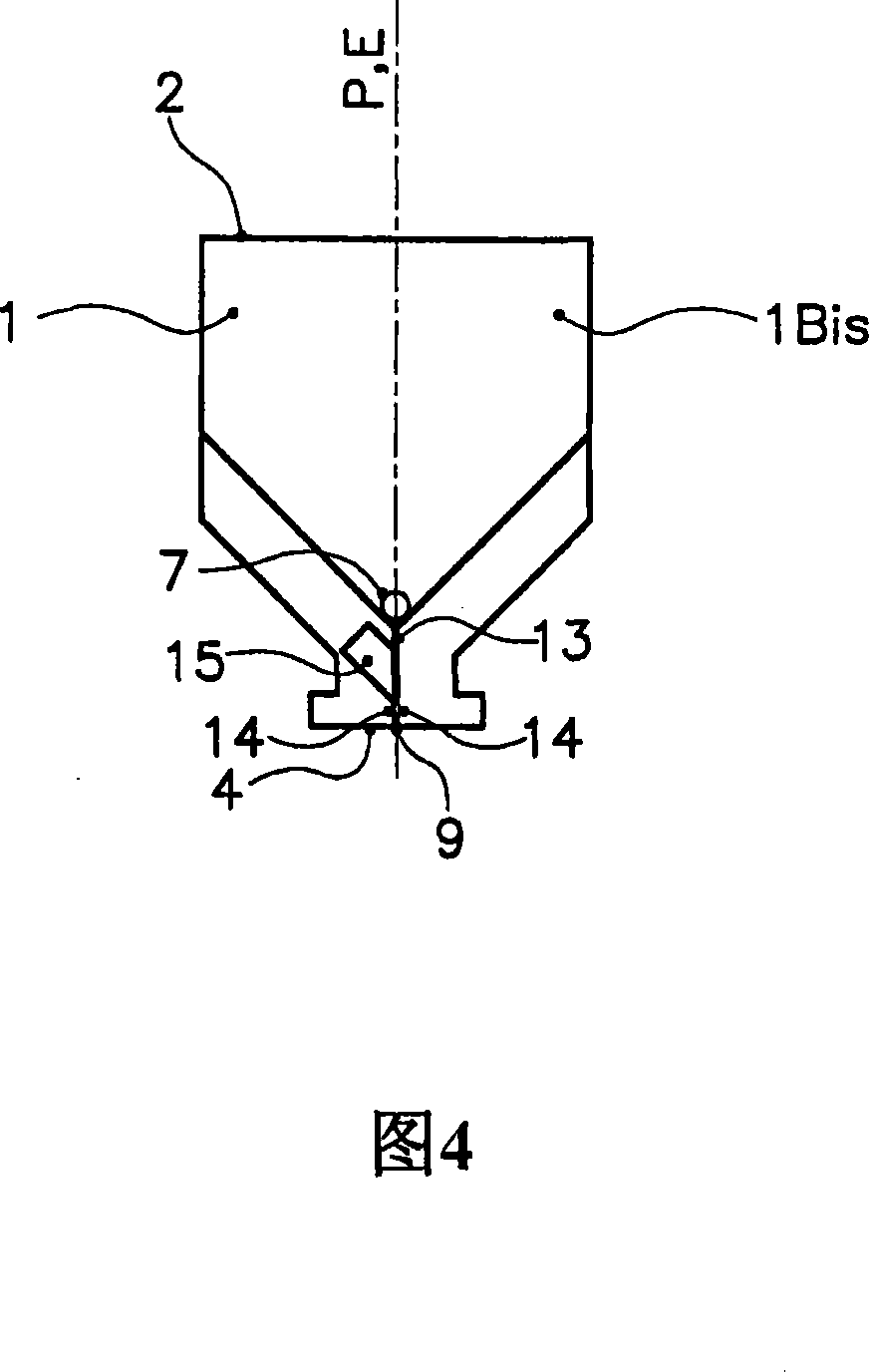

[0045] In the particular embodiment of the mold shown in the figures, the base 1 of the flat mold has an upstream edge 2 through which the molten plastic arrives through an inlet channel (not shown) and passes through the mold. The four orifices 3 and enter. Molten plastic is discharged through the downstream edge 4 . The upper part of the base 1 defines a flow plane (P) (only shown in FIG. 1 a ) in which a web of generally flat plastic flows within the mold 1 in a flow direction (E) (only shown in FIG. 1 a ).

[0046] The flat die shown comprises four grooves 5 for supplying molten plastic, which are placed parallel and equidistant from each other and in a flow plane (P) parallel to the flow direction (E) extend. Each feed trough 5 comprises a downstream orifice 6 for discharging the plastic into a distribution channel 7 in a direction (E) for distribution approximately perpendicular (considering its meandering shape) to the direction of flow (E). In the longitudinal direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com