Metro engineering pile foundation underpinning construction method

A construction method and technology of engineering piles, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of large investment, complicated construction process, and impact on the surrounding environment, and achieve the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

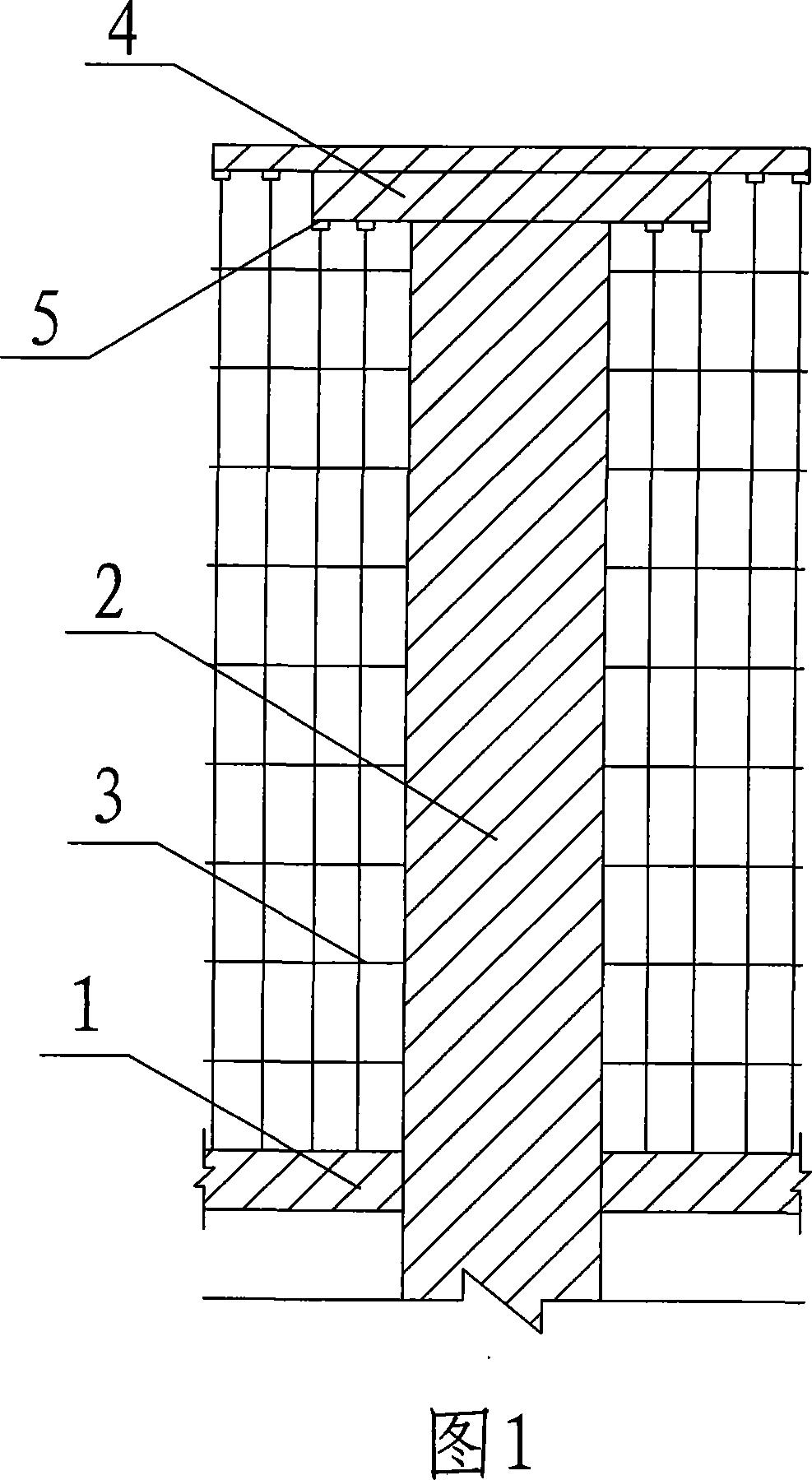

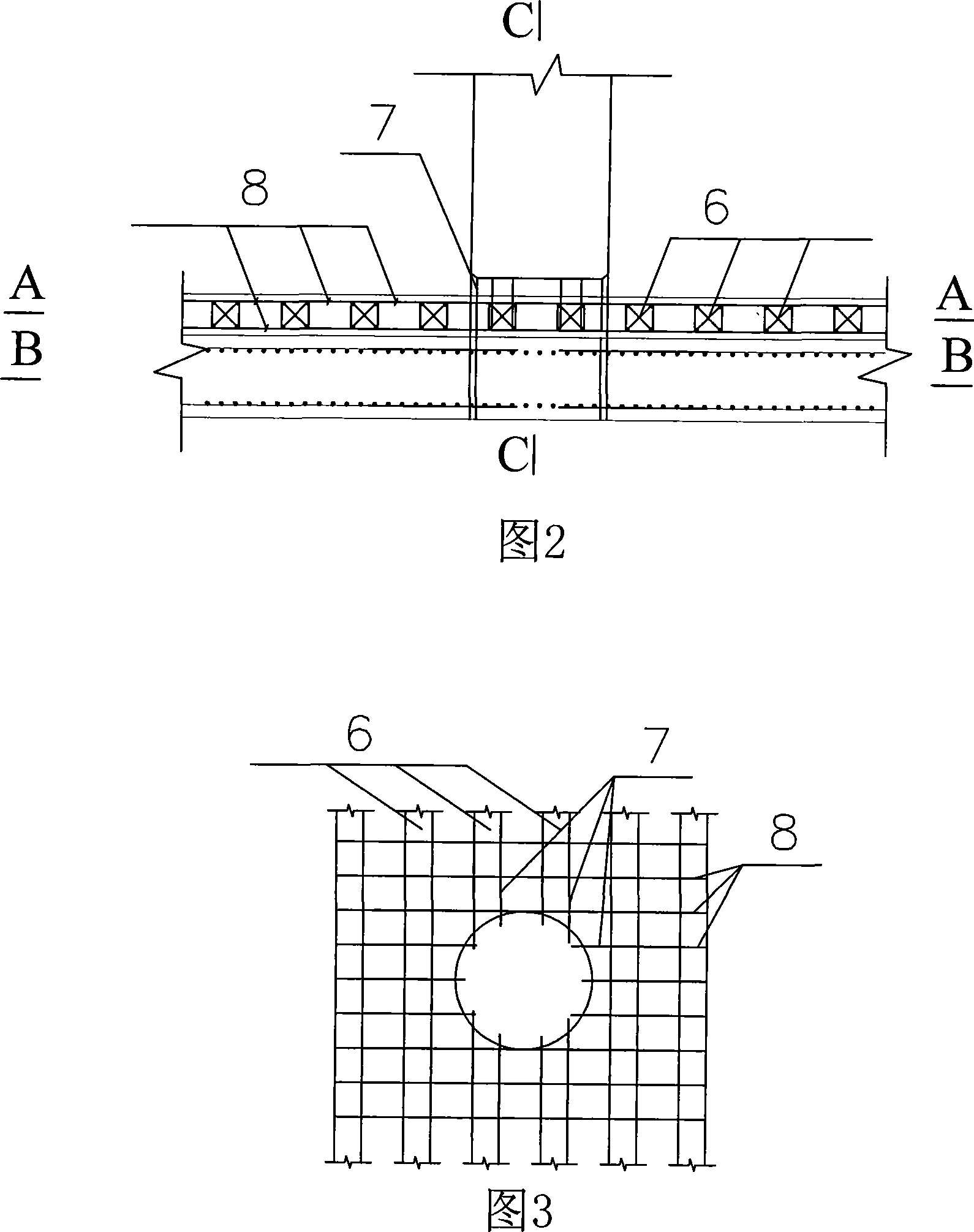

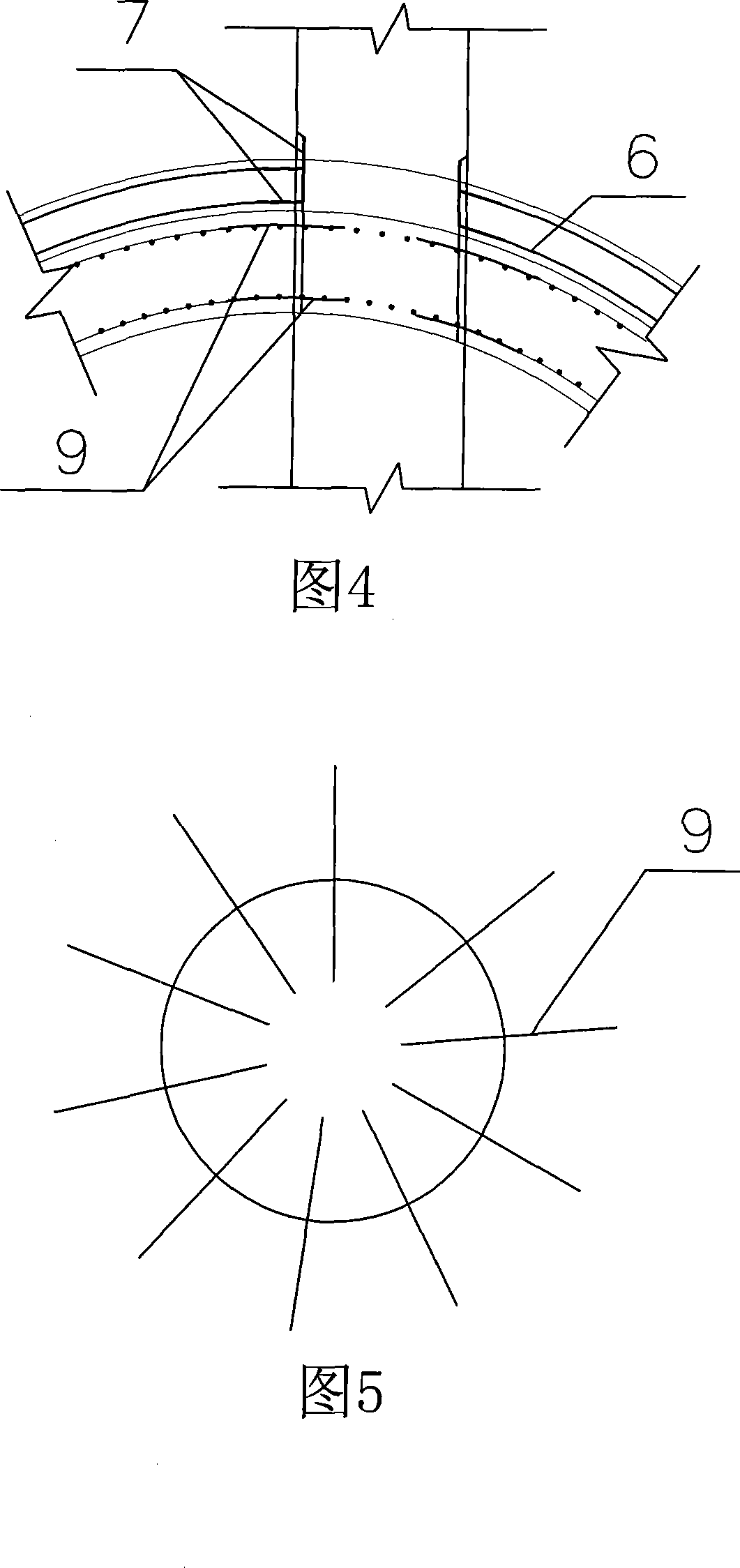

[0014] The tunnel between Huangzhuang Station and Kenan Road Station (hereinafter referred to as Huangke Section) of Beijing Metro Line 10 is constructed by shallow buried underground excavation method. The tunnel passes through Zhichun Road and runs east-west along Zhichun Road. The tunnel on the right line of the section passes under the pedestrian bridge of Zhichun Building at k2+629.983, and the section tunnel crosses the pile foundation of the bridge in space. This section is the bell-mouth separation section of the interval line, and the tunnel structure is in the form of a double-arch section, which is constructed by the middle-hole method. The main girder of the upper structure of Zhichun Building Pedestrian Bridge is a three-span continuous two-chamber closed steel girder, the ladder girder is a simply supported steel step plate, and the bridge piles are φ1000 bored piles with a length of 15.2m. The buried depth of the tunnel roof at this place is 8.348m. The main pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com