Method for producing dry bacterium powder containing gamma-linolenic acid

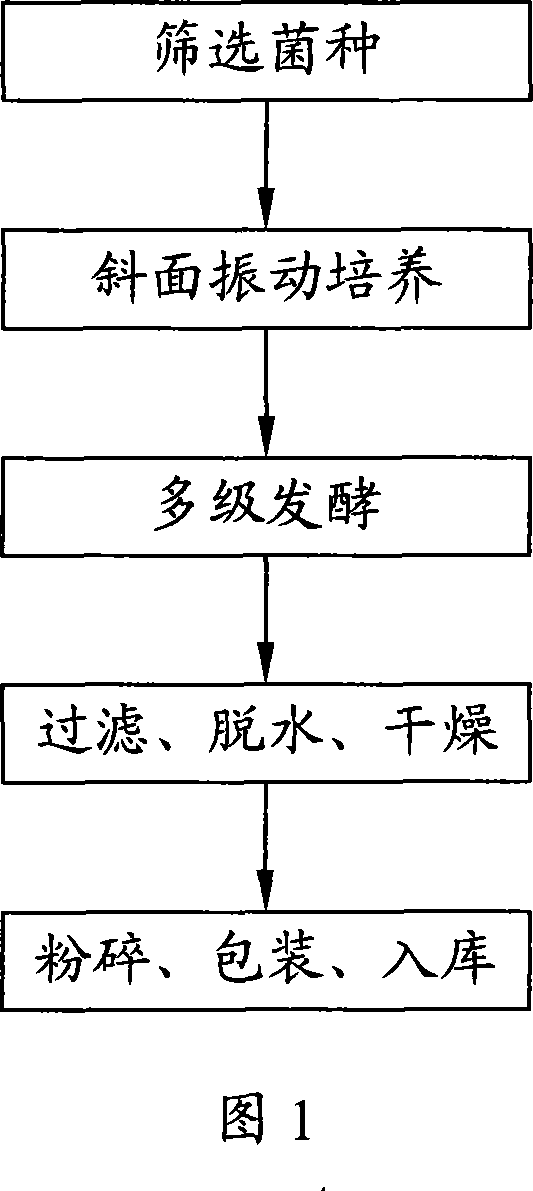

A production method, the technology of linolenic acid, is applied in the field of improvement of the process of producing dry bacterial powder containing γ-linolenic acid, which can solve the problems of affecting product quality and poor survival rate of strains, and achieve stable product quality, short production cycle, and guaranteed The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Use the γ-linolenic acid strains that exist in some spore plants and seed vegetable oils as culture and fermentation strains:

[0037] Screen the strains in the incubator;

[0038] The slant culture of the strain is to vibrate for 5 days at 25°C;

[0039] Fermented for 3 days at 25℃ in the first-level fermentation tank;

[0040] Fermentation for 4 days in a secondary fermentation tank at 25°C:

[0041] Fermented in a tertiary fermentation tank at 25°C for 3 days:

[0042] Fermented in a four-stage fermentation tank at 25°C for 4 days;

[0043] Then, the cells are filtered and dehydrated, and then dried under vibration at 25°C and 0.5 Pascal conditions or blow-dried in a vibration mode using air with a humidity of 20%-30% at -30°C.

[0044] Finally, it is crushed and sieved with an average particle size of 113 microns, and the products are aseptically vacuum packaged and stored in storage.

[0045] The above-mentioned slant culture means that the expanded cultured strains ar...

Embodiment 2

[0058] Use the γ-linolenic acid strains that exist in some spore plants and seed vegetable oils as culture and fermentation strains:

[0059] Screen the strains in the incubator;

[0060] The slant culture of strains is cultured at 28°C with shaking for 3 days;

[0061] Fermented for 3 days at 28℃ in the first-level fermentation tank;

[0062] Fermented for 3 days at 28°C in the secondary fermentation tank:

[0063] Fermented in a tertiary fermentation tank at 28°C for 3 days;

[0064] Fermented in a four-stage fermentation tank at 28°C for 4 days;

[0065] Vibrate drying at 25°C and 0.6 Pascal, or blow dry with air with a humidity of 25% at -30°C in a vibration mode.

[0066] Finally, it is crushed and sieved with an average particle size of 320 microns, and the products are aseptically vacuum packaged and stored in storage.

[0067] The slant culture refers to inoculating the expanded cultured strains in a liquid culture solution, shaking culture on a shaker at 150 rpm and shaki...

Embodiment 3

[0080] Use the γ-linolenic acid bacteria that exist in some spore plants and seed vegetable oils as the culture and fermentation bacteria:

[0081] Screen the strains in the incubator;

[0082] The slant culture of the strains is vibrated for 2 days at 32℃;

[0083] Fermented for 1 day at 32℃ in the first-level fermentation tank;

[0084] Fermented for 2 days at 30℃ in the secondary fermenter:

[0085] Fermented for 1 day at 32℃ in a tertiary fermentation tank;

[0086] Fermented in a four-stage fermentation tank at 30°C for 2 days;

[0087] After that, it was vibrated and dried under the conditions of 30°C and 0.4 Pascals, or was blow-dried in a vibration mode with air with a humidity of 30% at -20°C.

[0088] Finally, it is crushed and sieved with an average particle size of 216 microns, and the product is aseptically vacuum packaged and stored.

[0089] The slant culture means that the expanded cultured strains are inoculated in a liquid culture solution, and shake cultured on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com