Method for synthesizing zinc oxide particle

A technology of zinc oxide particles and synthesis method, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of high energy consumption, complex equipment, uneconomical and other problems, and achieve the effects of high purity, low equipment requirements and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

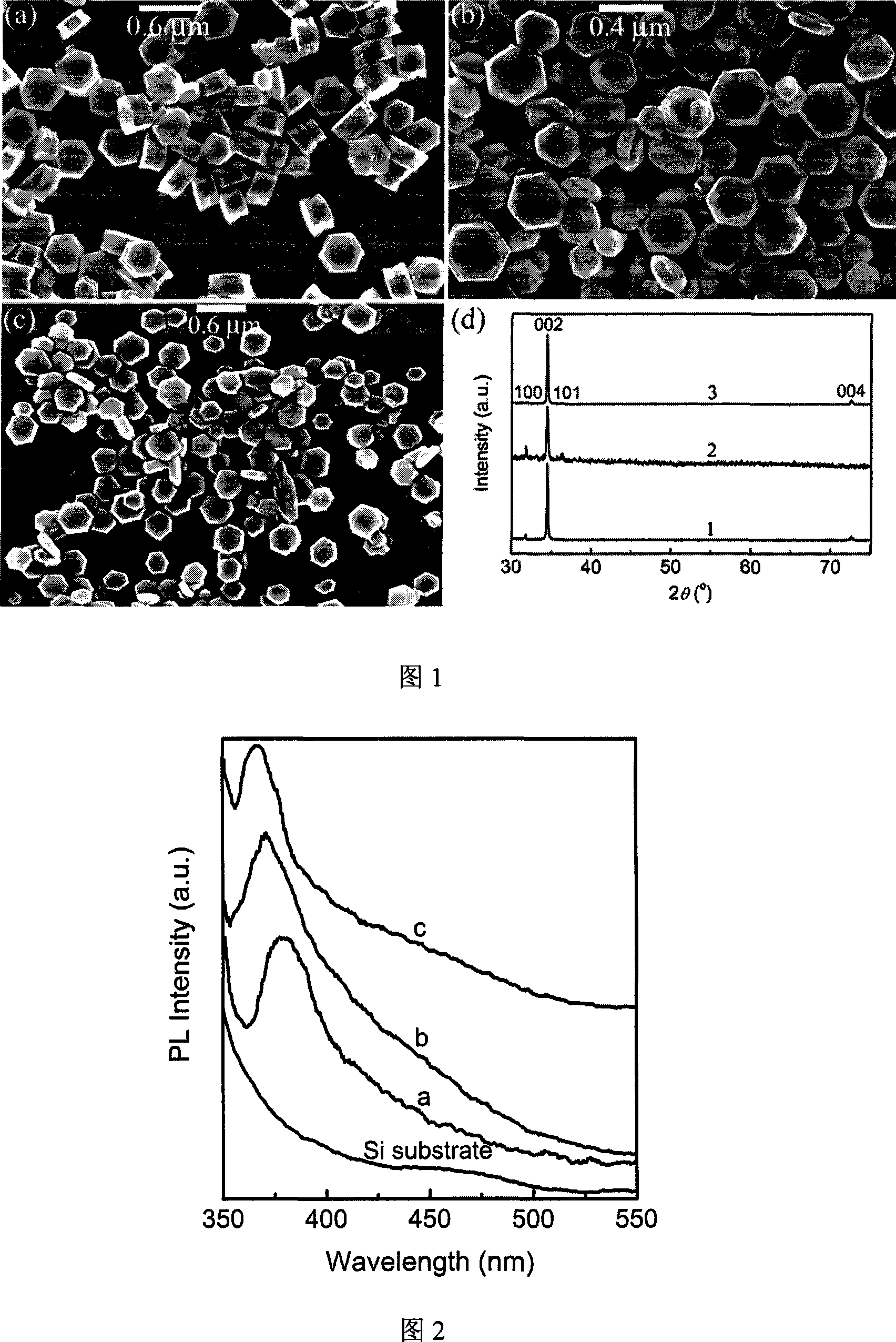

[0030] A total of 17 g of a ternary solution system of 0.15M sodium hydroxide aqueous solution (4.7%) / polyvinylpyrrolidone (0.6%) / n-amyl alcohol (94.7%) was prepared in a covered reaction vessel; then 0.6 g of zinc nitrate (0.1 M) The ethanol solution was added to the system under stirring, and the stirring was continued for 30 minutes at room temperature at 35°C for 36 hours; the standing reaction solution was centrifuged to obtain high-purity double-layer zinc oxide particles. 1a.

Embodiment 2

[0032] A total of 17.1 g of a ternary solution system of 0.15M sodium hydroxide aqueous solution (4.7%) / polyvinylpyrrolidone (1.2%) / n-amyl alcohol (94.1%) was prepared in a covered reaction vessel; then 0.6 g of zinc nitrate ( 0.1M) ethanol solution was added to the system under stirring, and the stirring was continued for 30 minutes at room temperature at 35°C for 36 hours; the standing reaction solution was centrifuged to obtain high-purity quasi-double-layer zinc oxide particles. See Figure 1b.

Embodiment 3

[0034] A total of 17.2 g of a ternary solution system of 0.15M sodium hydroxide aqueous solution (4.7%) / polyvinylpyrrolidone (1.8%) / n-amyl alcohol (93.5%) was prepared in a covered reaction vessel; then 0.6 g of zinc nitrate ( 0.1M) ethanol solution was added to the system under stirring, and the stirring was continued for 30 minutes at room temperature at 35°C for 36 hours; the standing reaction solution was centrifuged to obtain high-purity single-layer zinc oxide particles. Figure 1c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com