Zinc cobaltate nanorod/foam nickel composite electrode, preparation method thereof and application thereof

A composite electrode and nickel foam technology, used in capacitor electrodes, circuits, capacitors, etc., can solve the problems of single electrode structure, metal current collector and material conductivity, poor contact, small electrode damage surface area, etc., to increase the contact area, Conducive to the cycle performance, the production process is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

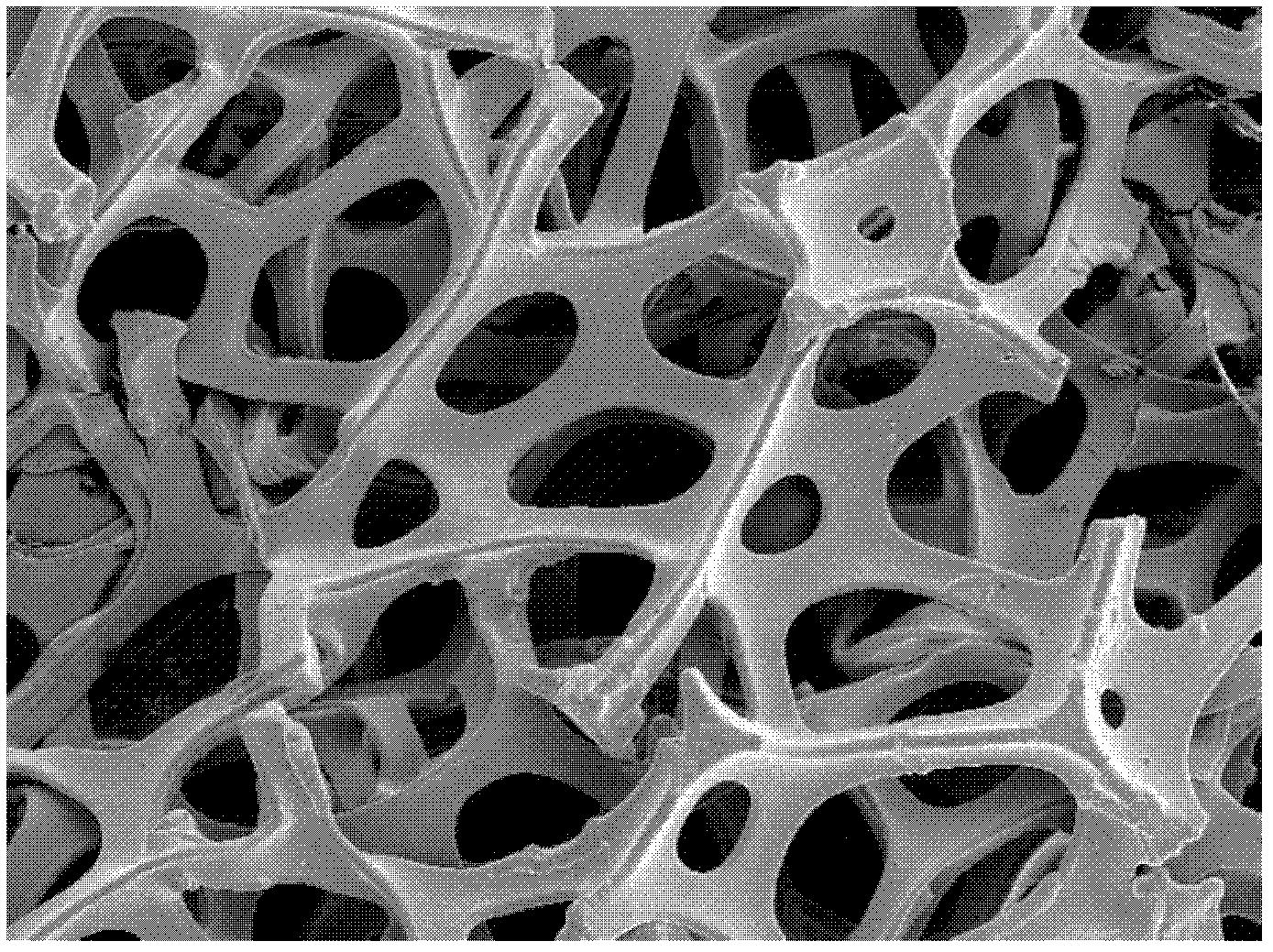

[0028] ① Dissolve zinc nitrate and cobalt nitrate in deionized water at a concentration of 0.017 mol / L and 0.033 mol / L at room temperature through thorough stirring to make solution A, and mix 3 to 4 pieces of cut foam Nickel sheet (such as figure 1 shown) soaked in the solution;

[0029] ② Dissolve oxalic acid in deionized water at a concentration of 0.3 mol / L by fully stirring at room temperature to make solution B; (the medicines used are all purchased directly, and the volume ratio of solutions A and B is 3:2)

[0030] ③ Add solution A and nickel foam into a three-necked flask, heat in a reflux reactor until the temperature stabilizes at 80°C, and stir at an appropriate speed;

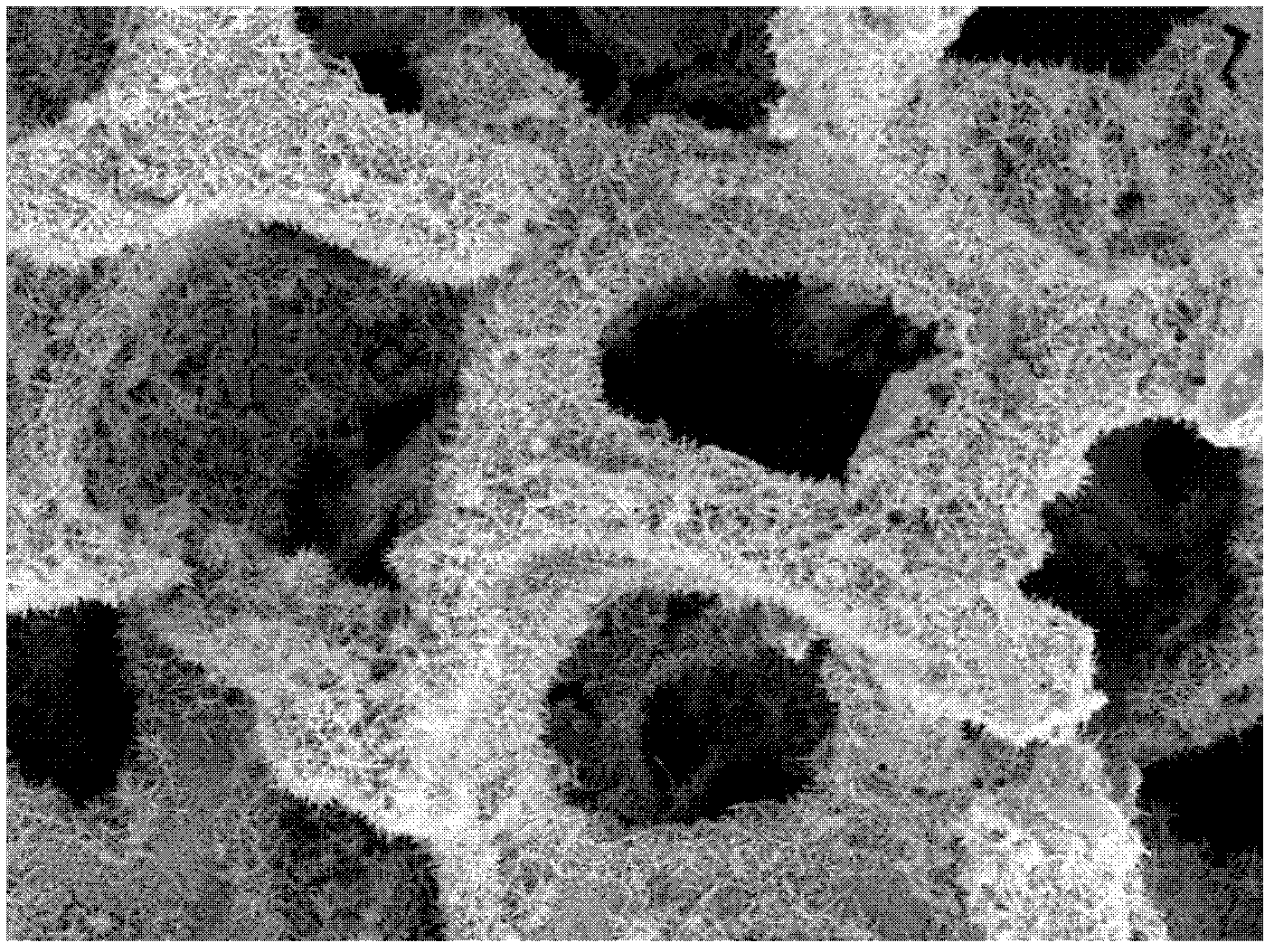

[0031] ④ Add the oxalic acid solution with a concentration of 0.2mol / L dropwise into the flask, and react at 80°C for 2 hours; Nickel sheets grow nanostructure precursors.

[0032] ⑤Take out the nickel sheet, wash and dry it, and put it into the muffle furnace for calcination. Annealed at 300°C...

Embodiment 2

[0034] ① Dissolve zinc nitrate and cobalt nitrate in deionized water at a concentration of 0.008 mol / L and 0.017 mol / L at room temperature through thorough stirring to make solution A, and mix 3 to 4 pieces of cut foam The nickel sheet is soaked in the solution;

[0035] ② Dissolve oxalic acid in deionized water at a concentration of 0.3 mol / L by fully stirring at room temperature to make solution B; (the medicines used are all purchased directly, and the volume ratio of solutions A and B is 3:2)

[0036] ③Add solution A and nickel foam into a three-necked flask, heat in a reflux reactor until the temperature stabilizes at 120°C, and stir at an appropriate speed;

[0037] ④ Add the oxalic acid solution with a concentration of 0.2mol / L into the flask dropwise and react at 120°C for 2 hours; the purpose of the oxalic acid solution is to make the reaction solution acidic. Nickel sheets grow nanostructure precursors.

[0038] ⑤Take out the nickel sheet, wash and dry it, and put ...

Embodiment 3

[0040] ① Dissolve zinc nitrate and cobalt nitrate in deionized water at a concentration of 0.034 mol / L and 0.066 mol / L at room temperature through thorough stirring to make solution A, and mix 3 to 4 pieces of cut foam The nickel sheet is soaked in the solution;

[0041] ② Dissolve oxalic acid in deionized water at a concentration of 0.3 mol / L by fully stirring at room temperature to make solution B; (the medicines used are all purchased directly, and the volume ratio of solutions A and B is 3:2)

[0042] ③Put solution A and nickel foam into a three-necked flask, heat in a reflux reactor until the temperature stabilizes at 150°C, and stir at an appropriate speed;

[0043] ④ Add the oxalic acid solution with a concentration of 0.2mol / L into the flask dropwise, and react at 150°C for 2 hours; Nickel sheets grow nanostructure precursors.

[0044] ⑤Take out the nickel sheet, wash and dry it, and put it into the muffle furnace for calcination. Annealed at 300°C for 120 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com