Pumping unit with pole

A technology for oil pumping and oil pumping mechanism, which is applied in the directions of transmission, production fluid, wellbore/well components, etc., can solve the problems of long operation time, energy waste, large volume and weight and manufacturing cost, and achieve the improvement of useful work power. , the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

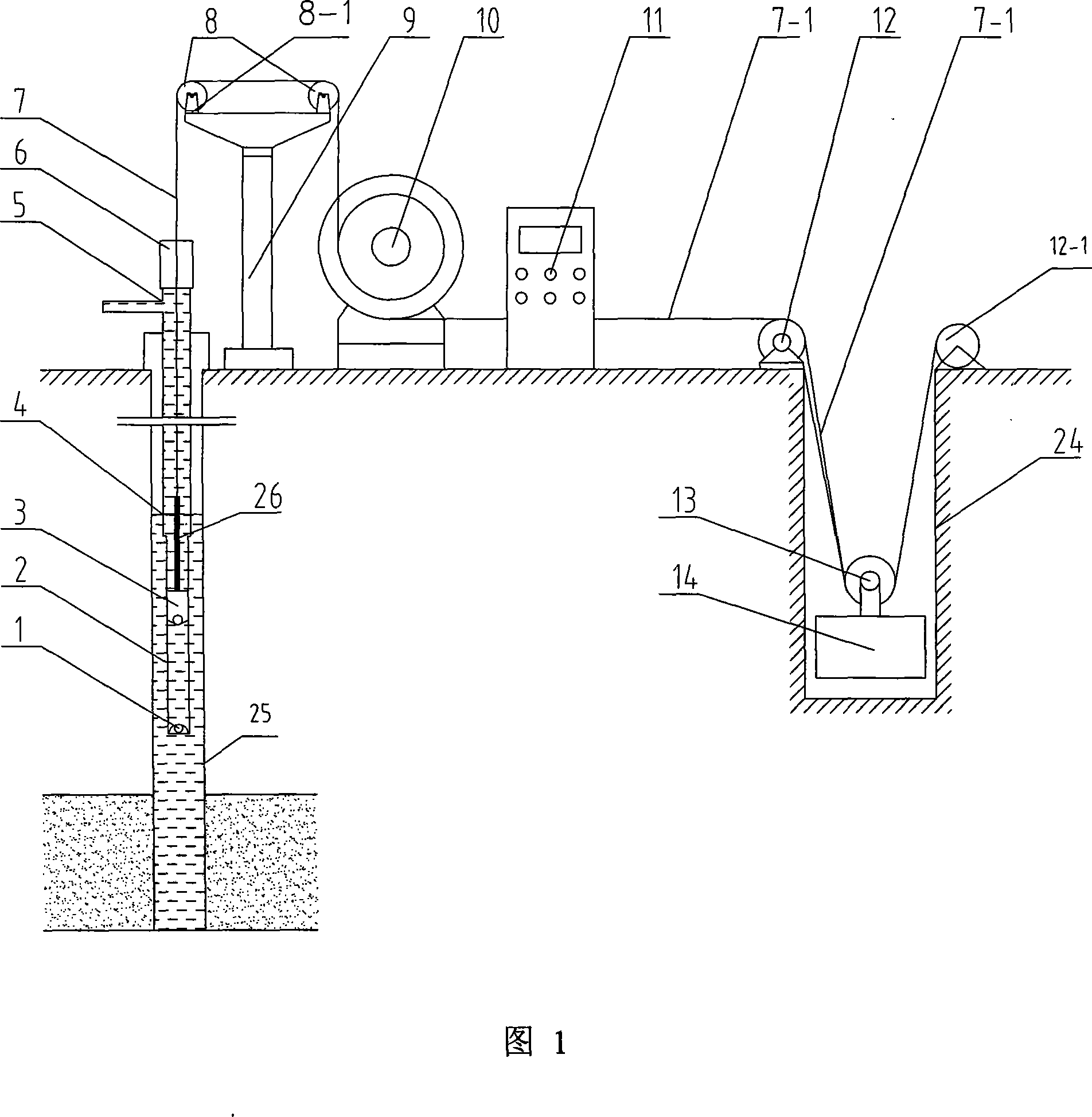

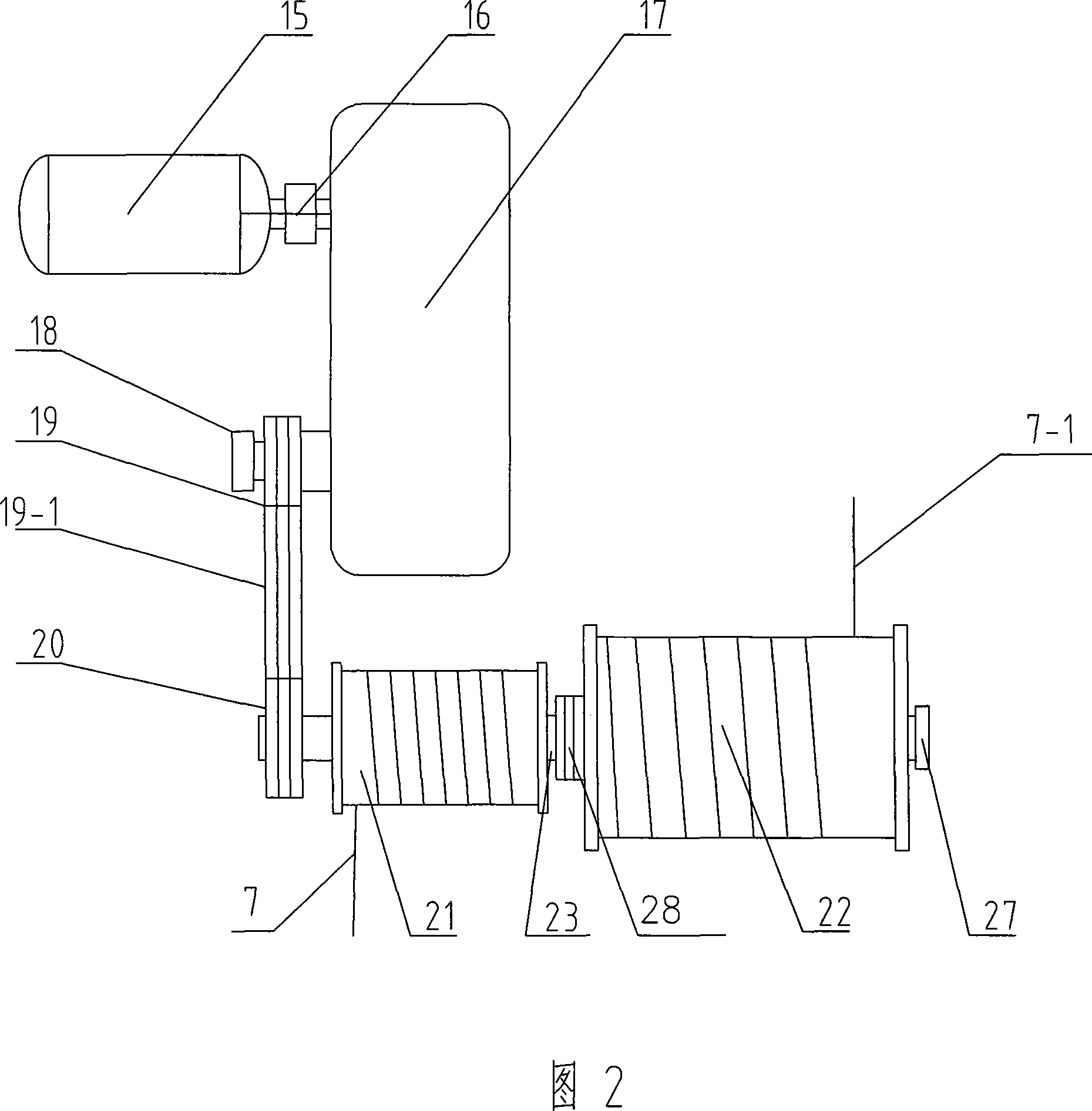

[0020] Embodiment 1: Referring to Figures 1 to 4, a rod pumping device includes a reducer 17 connected to a motor 15 via a coupling 16, an in-well pumping mechanism, and an electric control cabinet 11, characterized in that: Between the speed reducer 17 and the well pumping mechanism, a drum lifting mechanism connecting the two is added.

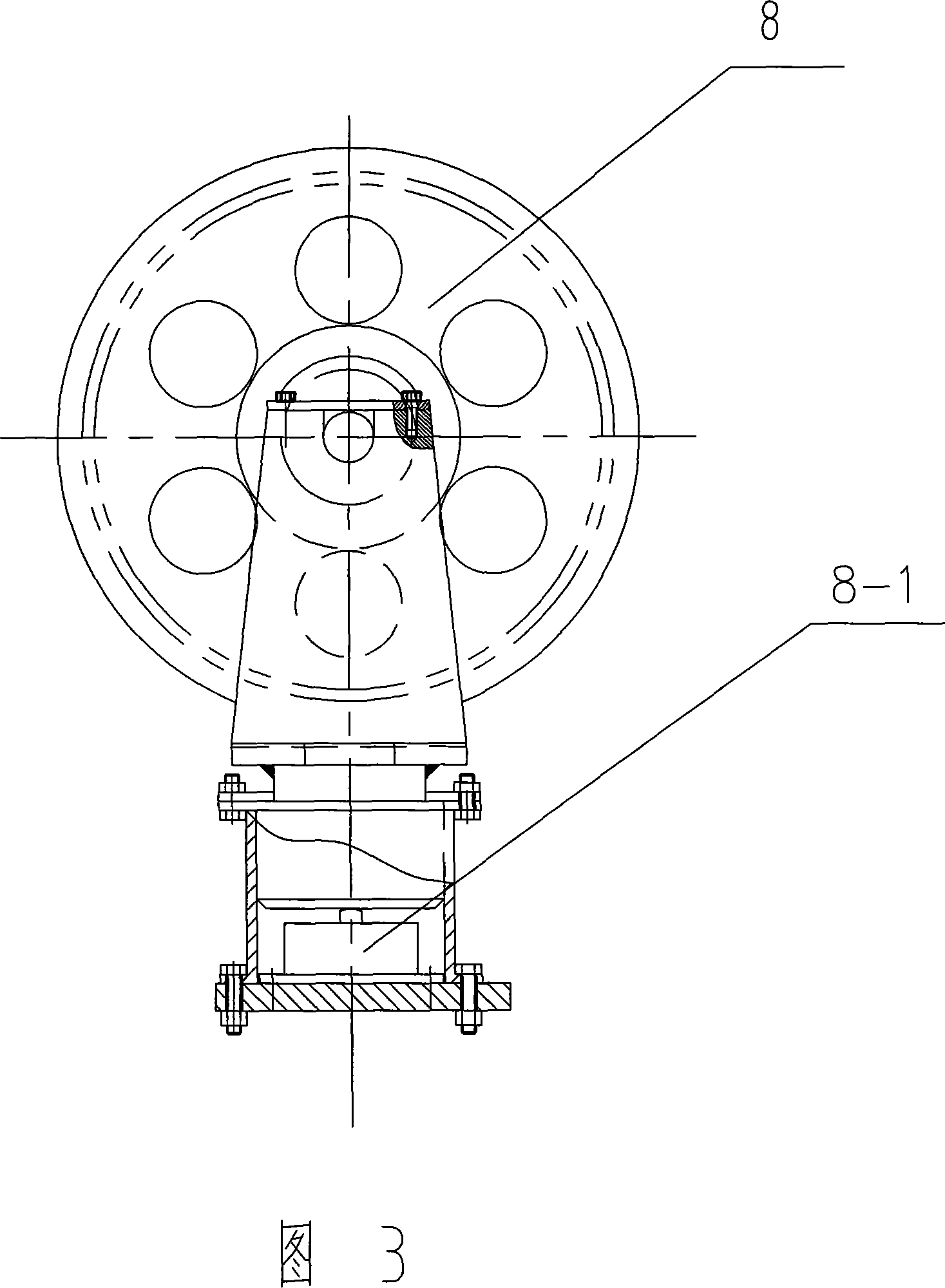

[0021]The drum lifting mechanism includes a double-drum winch 10, a steel wire rope 7 at the pumping end, a steel wire rope 7-1 at the counterweight end, a pulley support 9, a wellhead pulley 8, a redirection pulley 12, a counterweight movable pulley 13, and a movable pulley (13-1) , counterweight 14 and counterweight shaft 24; wherein, one end of the oil pumping end steel wire rope 7 is connected to the production drum 21 fixedly connected to one side on the drum shaft 23 of the double drum winch 10, and the counterweight end steel wire rope One end of 7-1 is connected to the counterweight drum 22 connected by the clutch 28 on the drum shaf...

Embodiment 2

[0024] Embodiment 2: Referring to Fig. 5, a rod oil pumping device, this embodiment is the same as Embodiment 1 except for the following structures:

[0025] 1. A counterweight support frame 29 is not provided with a counterweight well, and the counterweight support frame 29 is located above the ground, and the fixed pulleys of the counterweight support frame are fixedly connected by bolts on both sides of the top of the counterweight support frame (29) 29-1, the counterweight 14 is located on one side of the counterweight support frame 29, and the redirection pulley 12 is fixed on the ground near the other side of the counterweight support frame (29); the counterweight end The other end of steel wire rope 7-1 walks around described reversing pulley 12 and described counterweight supporting frame fixed pulley 29-1, and its end is connected with the top of described counterweight 14.

[0026] 2. The diameter of the production drum 21 is the same as that of the counterweight dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com