Method for manufacturing glass-ceramics

A manufacturing method and technology of glass-ceramics, applied in glass production, etc., can solve the problems of secondary pollution and high production costs, and achieve the effects of eliminating pollution, shortening processing time, and reducing taxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

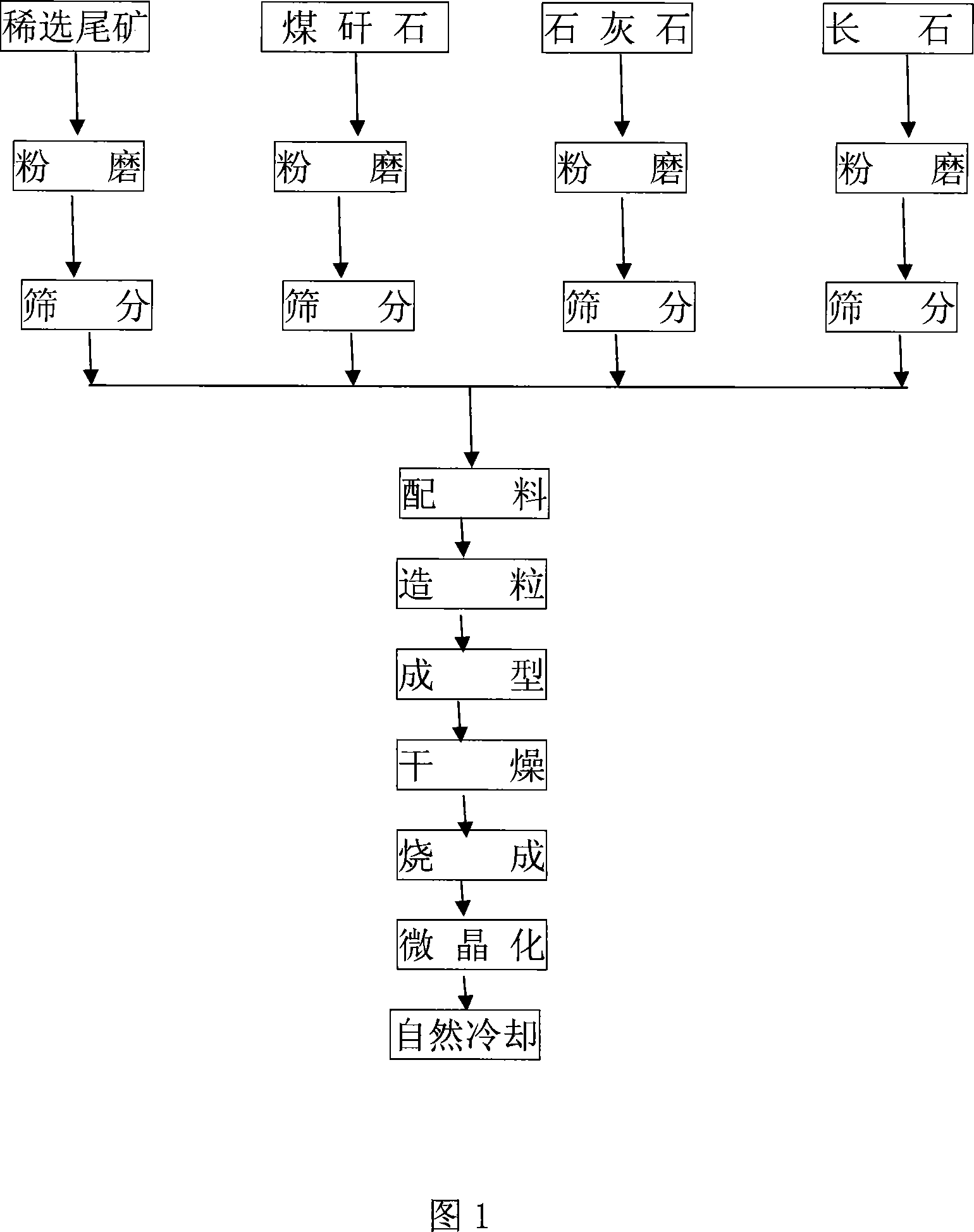

[0025] The process flow is shown in Figure 1,

[0026] 1. Powder preparation

[0027] The rare earth tailings used are taken from Baotou Iron and Steel Rare Earth Plant. The chemical composition of rare earth tailings is shown in Table 1; the chemical composition of coal gangue is shown in Table 2; the chemical composition of feldspar is shown in Table 3. Weigh the rare earth tailings, coal gangue and feldspar according to the ratio of raw materials: balls of 1:2, and put them into the ball mill tank (the total volume of the charge should be less than 2 / 3 of the ball mill tank volume), and ball mill for 24 hours.

[0028] 2. Screening

[0029] The ball-milled rare earth tailings powder, coal gangue, and feldspar powdered raw materials are respectively passed through a 325-mesh sieve, and the prepared powder is placed in a powder bag for later use.

[0030] 3. Ingredients

[0031] The rare earth tailings powder: feldspar: coal gangue are respectively weighed in a weight ratio of 10...

Embodiment 2

[0042] The process flow is shown in Figure 1,

[0043] 1. Powder preparation

[0044] The rare earth tailings used are taken from Baotou Iron and Steel Rare Earth Plant. The chemical composition of rare earth tailings is shown in Table 1; the chemical composition of coal gangue is shown in Table 2; the chemical composition of feldspar is shown in Table 3. Weigh the rare earth tailings, coal gangue and feldspar according to the ratio of raw materials: balls of 1:2, and put them into the ball mill tank (the total volume of the charge should be less than 2 / 3 of the ball mill tank volume), and ball mill for 24 hours.

[0045] 2. Screening

[0046] The ball-milled rare earth tailings powder, coal gangue, and feldspar powdered raw materials are respectively passed through a 325-mesh sieve, and the prepared powder is placed in a powder bag for later use.

[0047] 3. Ingredients

[0048] The rare earth tailings powder: feldspar: coal gangue are respectively weighed in a weight ratio of 10...

Embodiment 3

[0059] The process flow is shown in Figure 1,

[0060] 1. Powder preparation

[0061] The rare earth tailings used are taken from Baotou Iron and Steel Rare Earth Plant. The chemical composition of rare earth tailings is shown in Table 1; the chemical composition of coal gangue is shown in Table 2; the chemical composition of feldspar is shown in Table 3; and the chemical composition of limestone is shown in Table 4. Weigh the rare earth tailings, coal gangue, feldspar, and limestone according to the ratio of raw materials: balls of 1:2, and put them into the ball mill tank (the total volume of the material should be less than 2 / 3 of the ball mill tank volume), and ball mill for 24 hours.

[0062] 2. Screening

[0063] The ball-milled rare earth tailings powder and limestone, coal gangue, and feldspar powdery raw materials are respectively passed through a 325-mesh sieve, and the prepared powder is put into a powder bag for use.

[0064] 3. Ingredients

[0065] The rare earth tail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com