Method for preparing chemical aluminum oxide by using andalusite as raw material

A technology of andalusite and alumina, which is applied in the field of producing chemical alumina, can solve the problem of unusable tailings and achieve low cost, simple process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

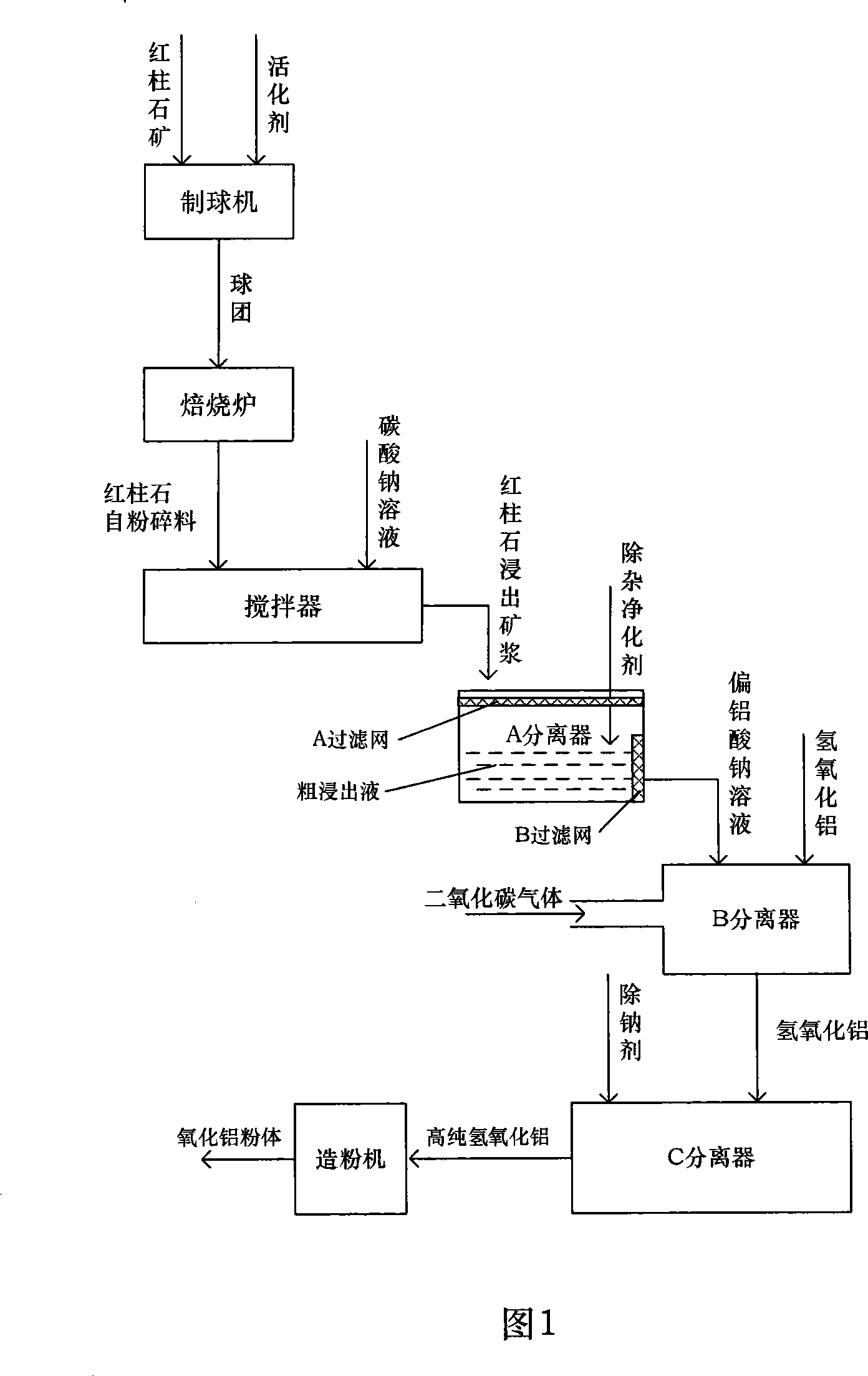

Method used

Image

Examples

Embodiment 1

[0045] The grade of alumina contained in the andalusite tailings is 45wt%, containing 46wt% of silicon oxide, 2wt% of ferric oxide, and the balance is other impurities.

[0046] The first step: crushing andalusite tailings into balls

[0047] After uniformly mixing 45 parts by weight of andalusite ore with a particle size less than 0.5 mm and 55 parts by weight of an activator with a particle size less than 0.5 mm, pellets with a particle size of 10 mm are obtained through a pelletizing machine;

[0048] Described activator is added the calcium fluoride CaF of 5 weight parts by the calcium oxide CaO of 100 weight parts 2 composition;

[0049] The second step: roasting andalusite self-grinding material

[0050] Roast the pellets prepared in the first step at a temperature of 1300°C for 60 minutes to obtain a calcined material;

[0051] Then the calcined material is moved out of the roasting furnace along with the crucible, and when the temperature of the calcined material in...

Embodiment 2

[0073] The grade of alumina contained in the andalusite tailings is 35wt%, containing 50wt% of silicon oxide, 8wt% of ferric oxide, and the balance is other impurities.

[0074] The first step: crushing andalusite tailings into balls

[0075] After uniformly mixing 50 parts by weight of andalusite ore with a particle size less than 0.5 mm and 50 parts by weight of an activator with a particle size less than 0.5 mm, pellets with a particle size of 60 mm are obtained through a pelletizing machine;

[0076] Described activator is added the calcium fluoride CaF of 1 weight part by the calcium oxide CaO of 100 weight parts 2 composition;

[0077] The second step: roasting andalusite self-grinding material

[0078] Roast the pellets prepared in the first step at a temperature of 1100°C for 90 minutes to obtain a calcined material;

[0079] Then the calcined material is moved out of the roasting furnace along with the crucible. When the temperature of the calcined material in the ...

Embodiment 3

[0103] The grade of alumina contained in the andalusite tailings is 52wt%, containing 38wt% of silicon oxide, 4wt% of ferric oxide, and the balance is other impurities.

[0104] The first step: crushing andalusite tailings into balls

[0105] After uniformly mixing 40 parts by weight of andalusite ore with a particle size less than 0.5 mm and 60 parts by weight of an activator with a particle size less than 0.5 mm, pellets with a particle size of 30 mm are obtained through a pelletizing machine;

[0106] Described activator is added the calcium fluoride CaF of 3 weight parts by the calcium oxide CaO of 100 weight parts 2 composition;

[0107] The second step: roasting andalusite self-grinding material

[0108] Roasting the pellets prepared in the first step at a temperature of 1200°C for 90 minutes to obtain a calcined material;

[0109] Then the calcined material is moved out of the roasting furnace along with the crucible. When the temperature of the calcined material in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com