Crane for handling of chains, wires, etc., and tools for same

A crane and cable technology, which is used in cranes, transportation and packaging, anchoring processing/bundling, etc., can solve the problems of high risk and heavy manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

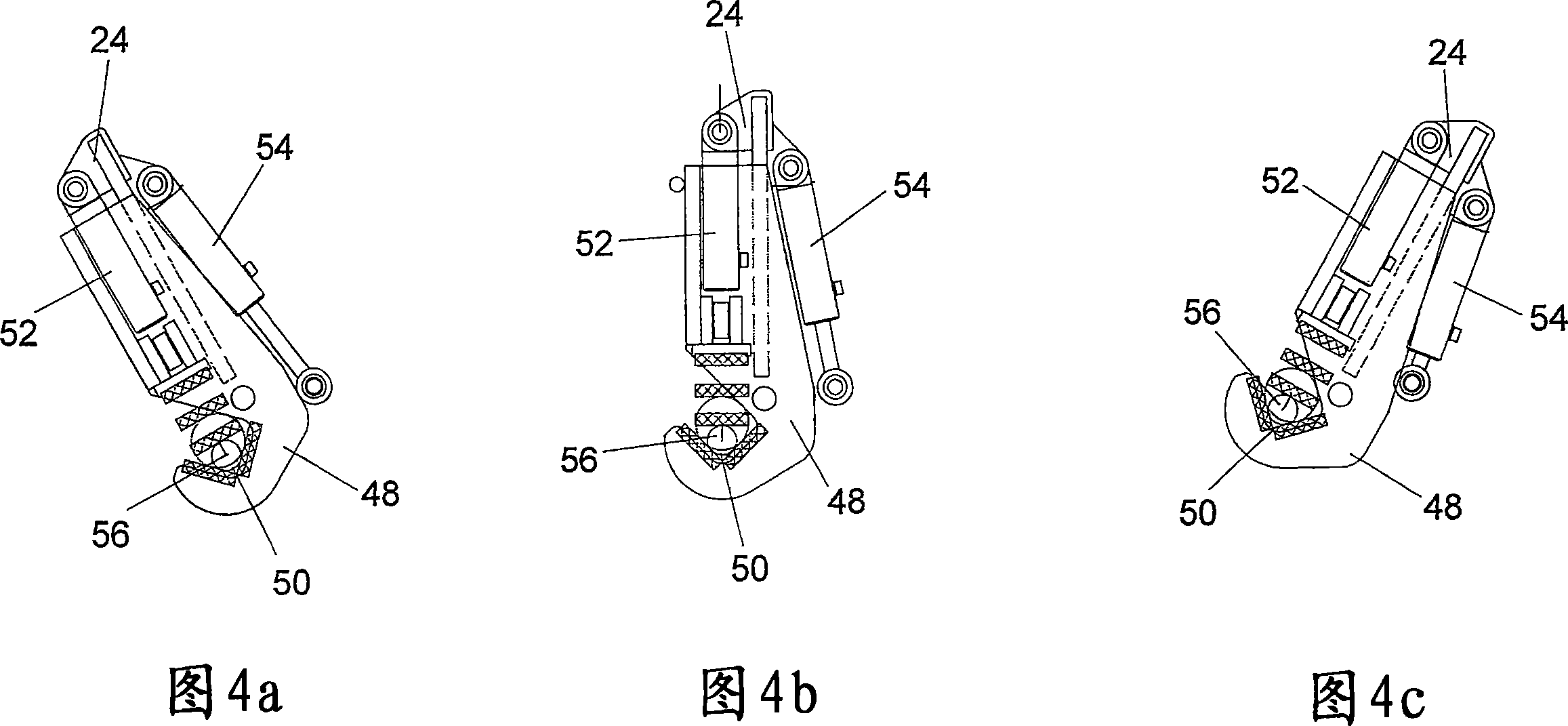

[0024] Figure 1 shows a crane 10 for installation on or adjacent to a working deck of a ship, a so called anchor working crane. The crane 10 includes a base 12 and a main boom 14 driven in a conventional manner by one or more pressure cylinders 26, such as hydraulic cylinders. As mentioned above, the anchor working crane 10 according to the present invention can be installed on each side of the working deck of the ship. The crane can move along the ship on rails, for example on top of the cargo rails, and the base 12 may therefore include means to enable such movement. The crane can rotate 360 degrees and thus has access to the entire working deck, behind the stern drum, outboard of the ship's side and to the winches located in front of the working deck. It should be noted that even if the expression "anchor-handling crane" is used, the crane is not limited to handling anchors only, but can also be used for other work operations on board the ship.

[0025] At least two wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com