Mounting device, plasma processing apparatus and plasma processing method

A plasma and carrier technology, applied in the directions of plasma, chemical instruments and methods, cleaning methods and utensils, etc., to achieve the effects of increased durability and high plasma resistance

Inactive Publication Date: 2008-05-14

TOKYO ELECTRON LTD

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Regarding these problems, nothing is described in Patent Document 2

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0066] Experiments performed to confirm the effects of the present invention will be described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

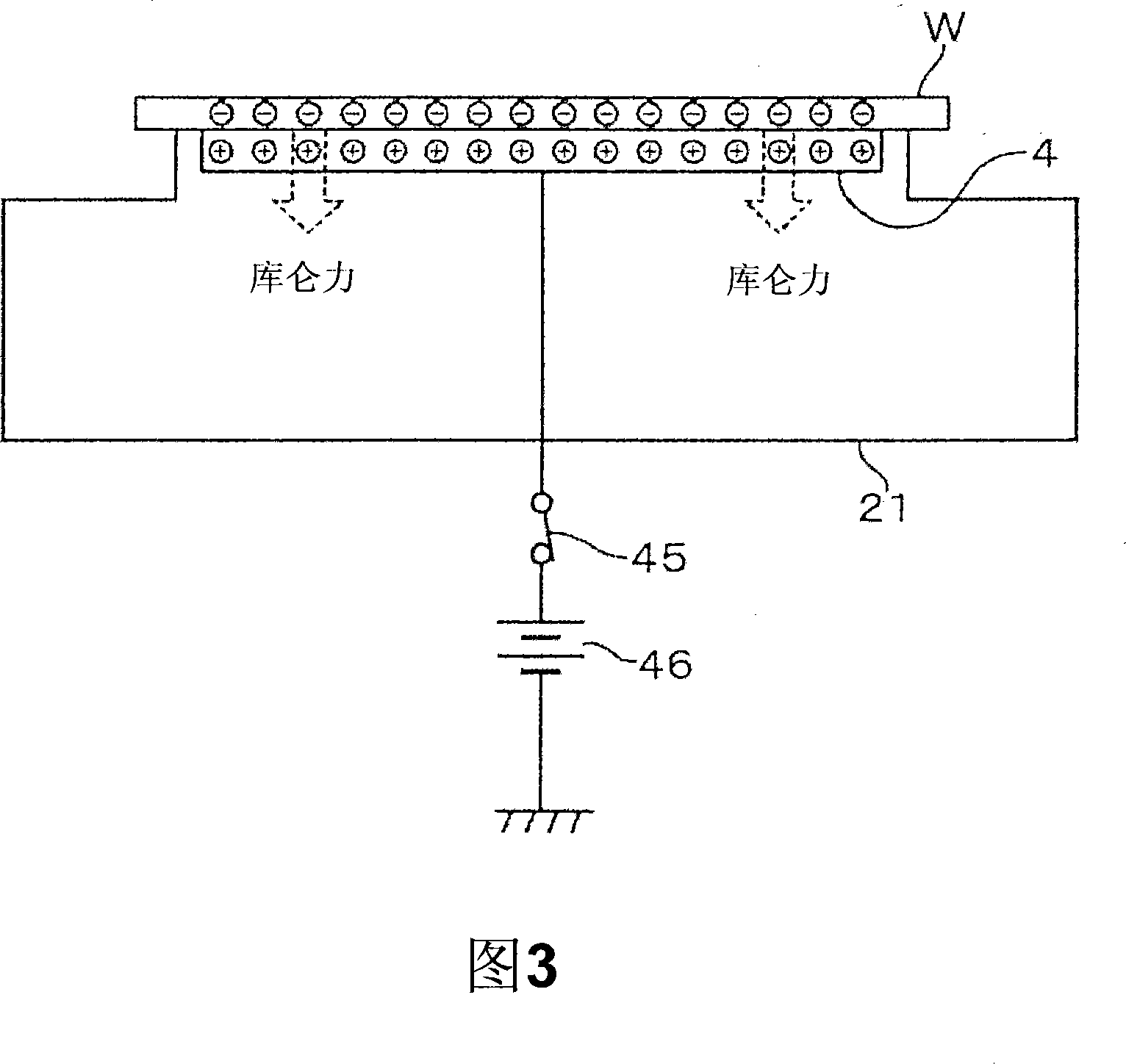

The invention provides a mounting device which has no heavy metallic pollution on the processed object, and is unable to cause insulation damage after a long-time static chuck. The invention is made by adopting the static chuck which is used as the insulation layer of the surface of the electrode layer through plasma spray plating, consisting of an yttria spray plating layer whose thickness is 200um to 280um. The surface of the invention is formed with a structure depending on the surface rough degree of the grain diameter of the spray plated yttria. The structure can increase the durability of the plasma without causing any heavy metallic pollution.

Description

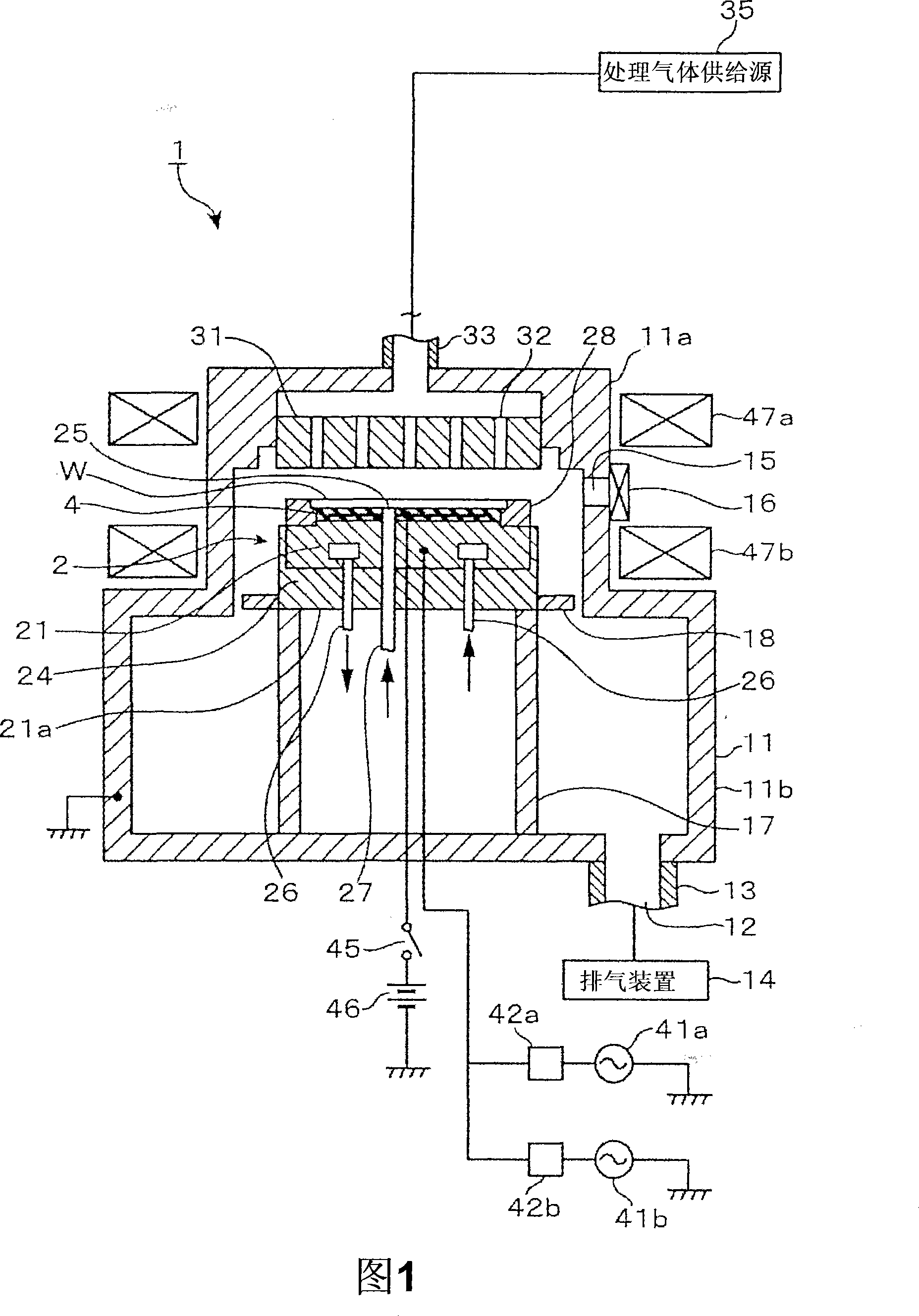

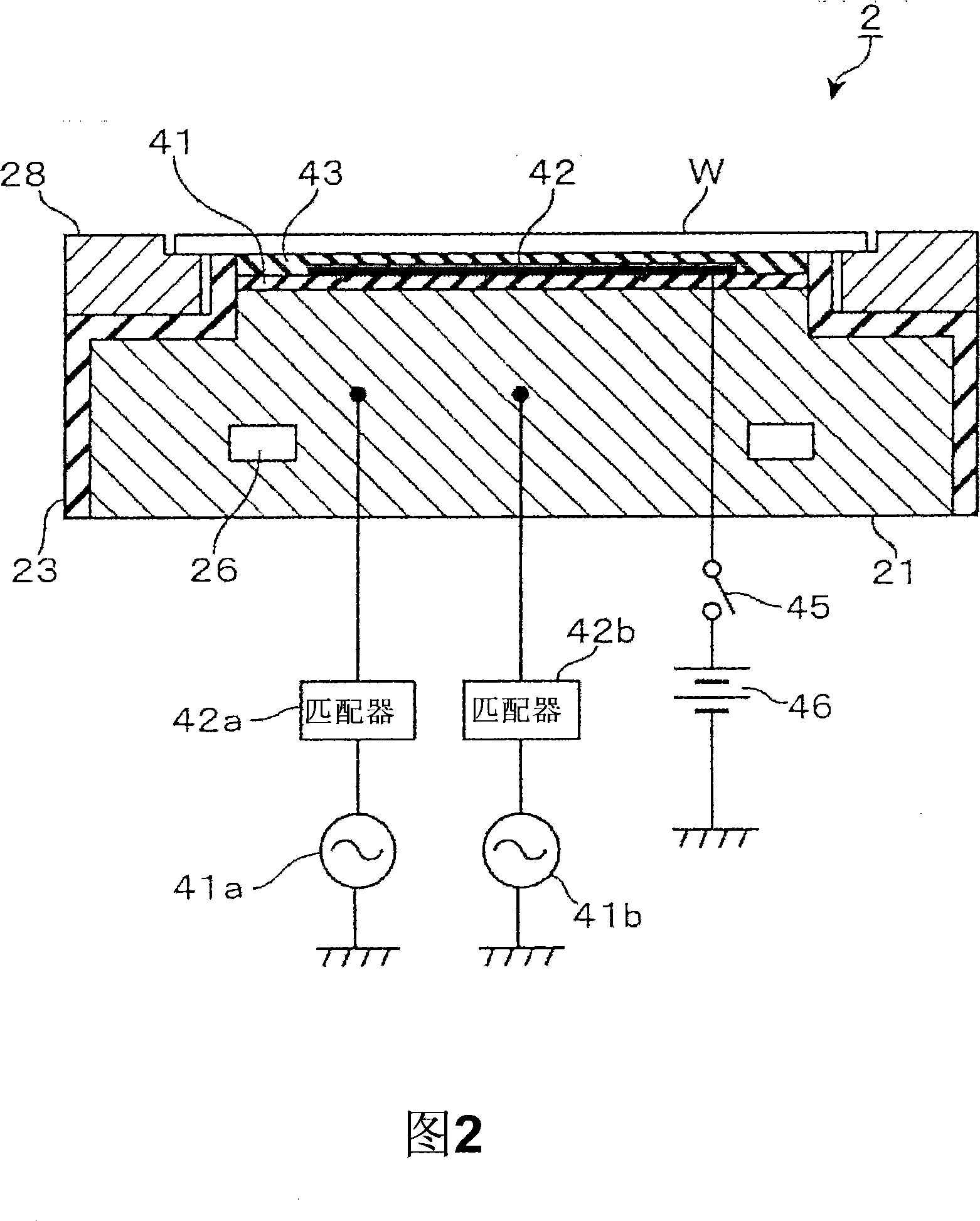

technical field [0001] The present invention relates to a mounting device provided with an electrostatic chuck layer that electrostatically adsorbs an object to be processed such as a semiconductor wafer, a plasma processing apparatus provided with the mounting device, and a plasma processing method. Background technique [0002] Mounting device used in a plasma processing device that performs plasma processing such as etching and CVD (Chemical Vapor Deposition), because a vacuum chuck cannot be used as a unit for holding a substrate on a mounting device , so use a general electrostatic chuck. [0003] An electrostatic chuck is placed on the surface of a carrier in a thin plate shape, a foil-shaped electrode is buried in an insulating layer, and the substrate is attracted to the electrostatic chuck by electrostatic force generated by applying, for example, a DC voltage to the electrode. function on the surface. [0004] When vacuum processing, such as plasma processing, is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/683H01L21/67H01L21/3065H01L21/311H01L21/3213H01L21/02H01L21/00H01J37/32H05H1/00B08B7/00C23F4/00C23C16/44

CPCH01J37/32862H01L21/6833

Inventor 伊藤弘治加藤健一上田雄大

Owner TOKYO ELECTRON LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com