Method and special-purpose equipment for electric wire and cable increasing operation of clipping and signal

A technology for wire and cable and special equipment, applied in the field of wire and cable cutting and marking, can solve the problems of wasted material cost, warehouse management manpower and material cost, unnecessarily increased procurement cost, difficult operation cost, etc., and achieves time-saving and labor-saving work efficiency and correctness, eliminate the phenomenon of residual material loss, and reduce the effect of material inventory management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

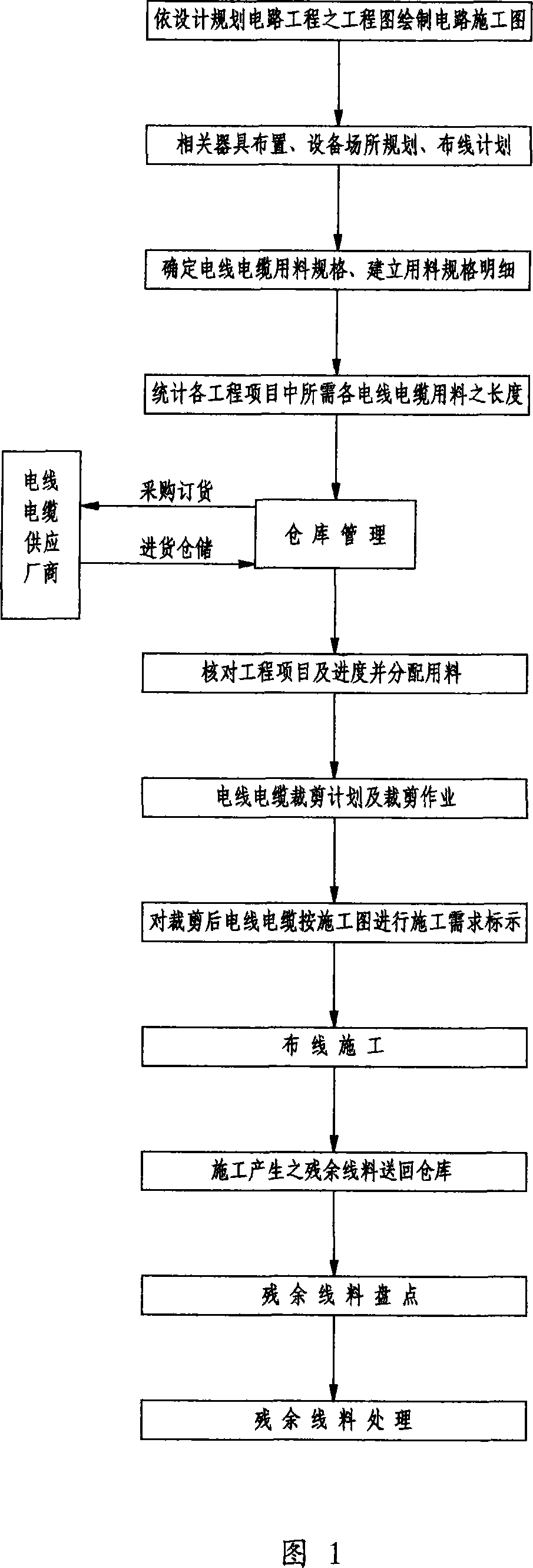

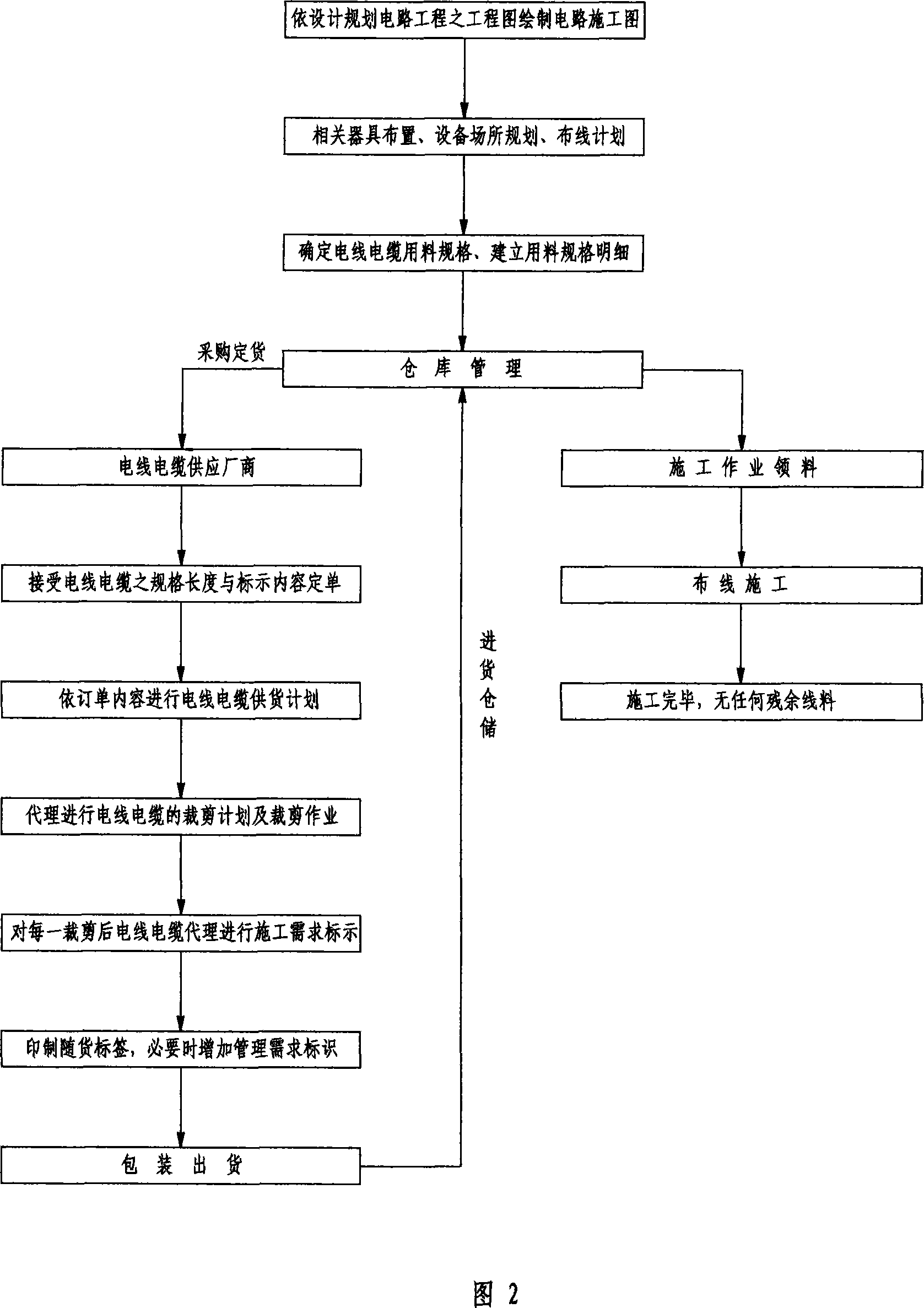

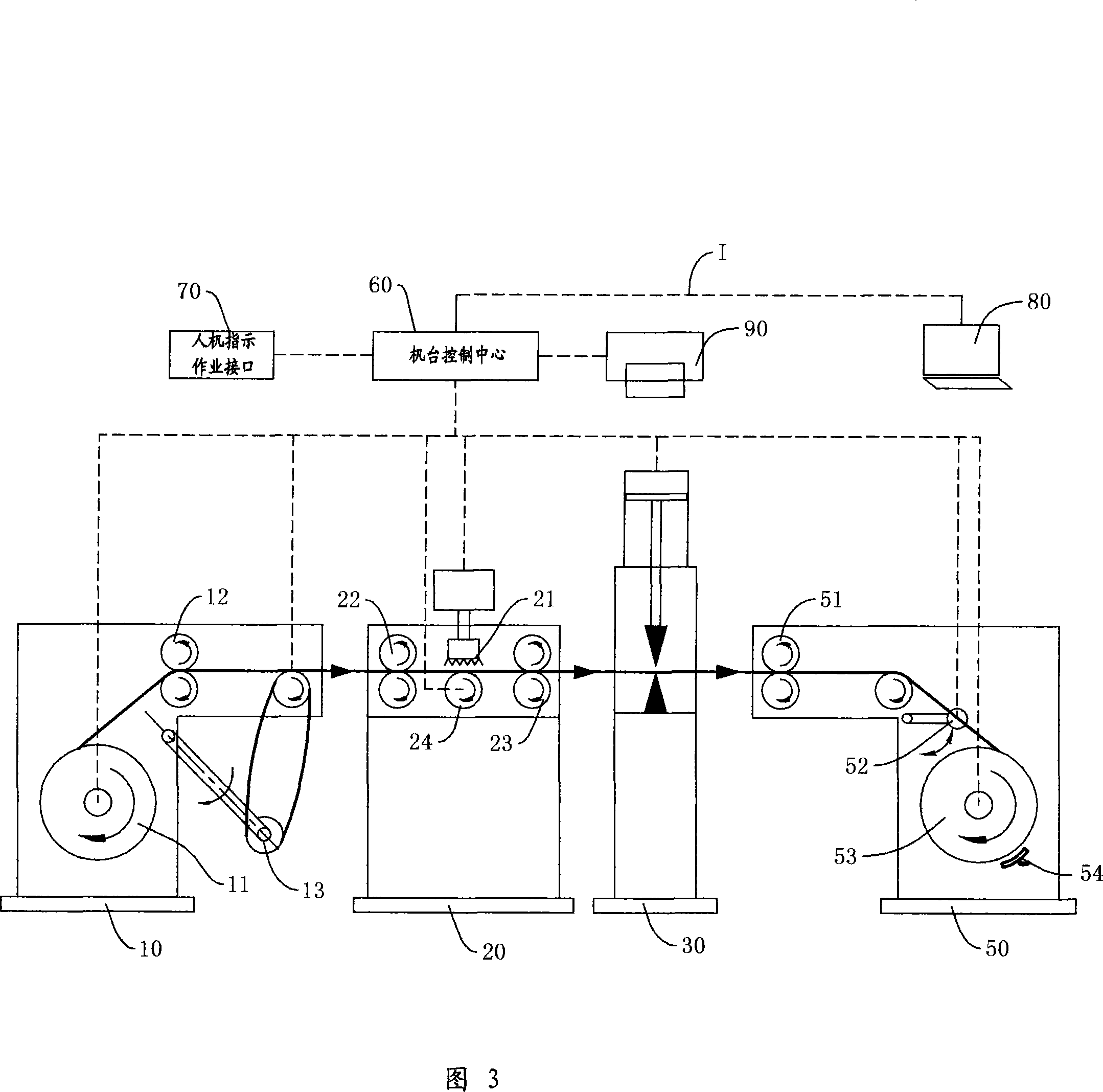

[0062] Here, the detailed operation and the construction process step diagram of the accompanying drawings are described in detail, so as to facilitate a further understanding of the present invention.

[0063] As shown in Figure 2, the operation method of adding cutting and labeling to the wire and cable of the present invention is:

[0064] The wire and cable supplier accepts the order from the consumer to provide statistics on the specifications, lengths, and labeling content of each wire and cable material used in various engineering projects; the information in the order is for the consumer to first plan according to the design. For circuit engineering projects, draw the circuit design and construction drawings; then make the installation and layout of related appliances, equipment site planning, and wiring (wire and cable) plans; then confirm the specifications of wire and cable materials, and establish detailed management of material specifications; The cable supplier p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com