Double sealings high-pressure grease pouring valve

A grease injection valve and double-sealing technology, which is applied to engine components, engine lubrication, lubricating parts, etc., to achieve the effects of preventing medium leakage, long service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

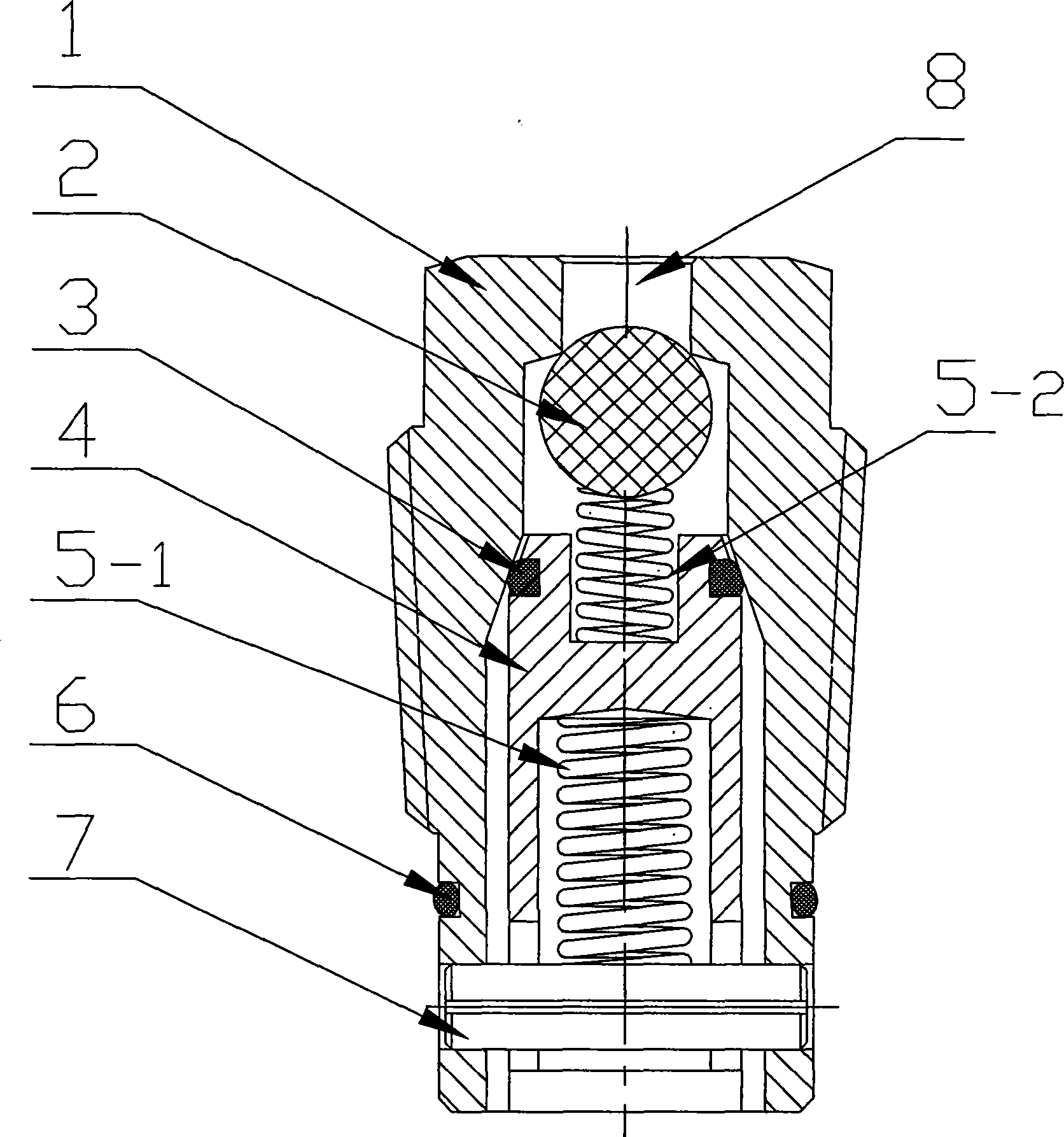

[0009] As the embodiment shown in the drawings, the double-seal high-pressure grease injection valve of the present invention includes a valve body 1 and a valve tip 4. The valve tip 4 is placed in the inner cavity of the valve body 1 and supported on the valve body by the first spring (5-1). body (1); the upper part of the valve tip 4 is provided with a movable hard-sealed ball 2, and the hard-sealed ball 2 is supported on the upper part of the valve tip by the second spring 5-2, and the movable hard-sealed ball 2 and the grease injection hole 8 in the inner cavity of the valve form a Spherical line seal, the hard seal ball 2 can be a steel ball; the conical surface of the valve tip 4 is provided with an elastic sealing ring 3, and the elastic sealing ring 3 contacts and seals with the conical surface in the grease injection hole 8 of the valve inner cavity, and the elastic sealing ring 3. It is best to use fluorine rubber O-ring to adapt to the harsh environment. Grease is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com