Method for synthesizing cationic starch

A technology of cationic starch and cationic etherification agent, which is applied in the field of synthesis of cationic starch, can solve the problems of difficult sewage treatment, low reaction efficiency, low degree of substitution, etc., and achieve the effect of moderate viscosity, high purity and moderate degree of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

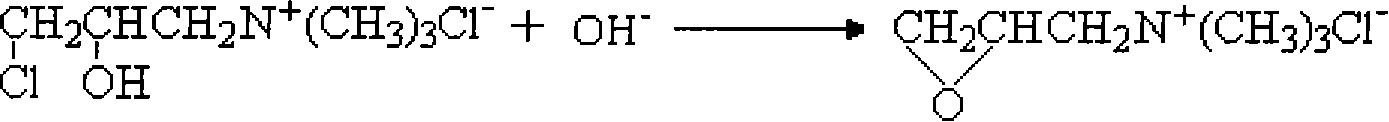

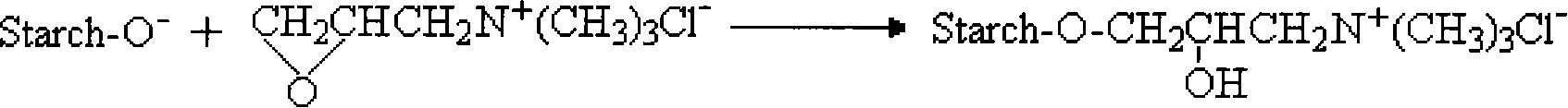

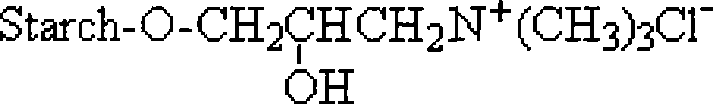

Method used

Image

Examples

Embodiment 1

[0029] In a 250ml three-neck round bottom flask equipped with an electric stirrer, add 25g of sweet potato starch and 58ml of water to form a starch suspension. After mixing evenly, slowly add 25ml of 3% NaOH solution dropwise, and alkalize at 40°C for 15 minutes. Slowly add a cationic etherification agent of 6.0% starch mass for 45 minutes, and then raise the temperature to 90° C. for 2 hours. Cool down, neutralize with 5 mole hydrochloric acid, and get the finished product after treatment. The 3% gelatinized solution was placed at room temperature for 100 hours without stratification. The degree of substitution of the finished product synthesized in this embodiment is 0.039.

Embodiment 2

[0031] In a 250ml three-necked round-bottom flask, equipped with an electric stirrer, add 25g of sweet potato starch and 62.2ml of water to form a starch suspension. After mixing evenly, slowly add 20.8ml of 3% NaOH solution dropwise, and alkalize at 40°C for 15 minutes Finally, a cationic etherification agent of 6.0% by weight of the starch was slowly added dropwise for 45 minutes, and then the temperature was raised to 90° C. for 2 hours. Cool down, neutralize with 5 mole hydrochloric acid, and get the finished product after treatment. The 3% gelatinized solution was placed at room temperature for 100 hours without stratification. The degree of substitution of the finished product synthesized in this embodiment is 0.022.

Embodiment 3

[0033] In a 250ml three-neck round bottom flask equipped with an electric stirrer, add 25g of sweet potato starch and 58ml of water to form a starch suspension. After mixing evenly, slowly add 25ml of 3% NaOH solution dropwise, and alkalize at 40°C for 15 minutes. Slowly add a cationic etherification agent of 6.0% starch mass for 45 minutes, and then raise the temperature to 60° C. for 4 hours. Cool down, neutralize with 5 mole hydrochloric acid, and get the finished product after treatment. The 3% gelatinized solution was placed at room temperature for 100 hours without stratification. The degree of substitution of the finished product synthesized in this embodiment is 0.028.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com