Novel technique for preparing tea saponin by solvent extraction and selectively separating integration

A technology of tea saponin and selectivity, which is applied in the field of integrated preparation of tea saponin by solvent extraction and selective separation, can solve the problems of cumbersome steps, no consideration of cake utilization, and large reagent consumption, so as to improve extraction efficiency and save The effect of consumption and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

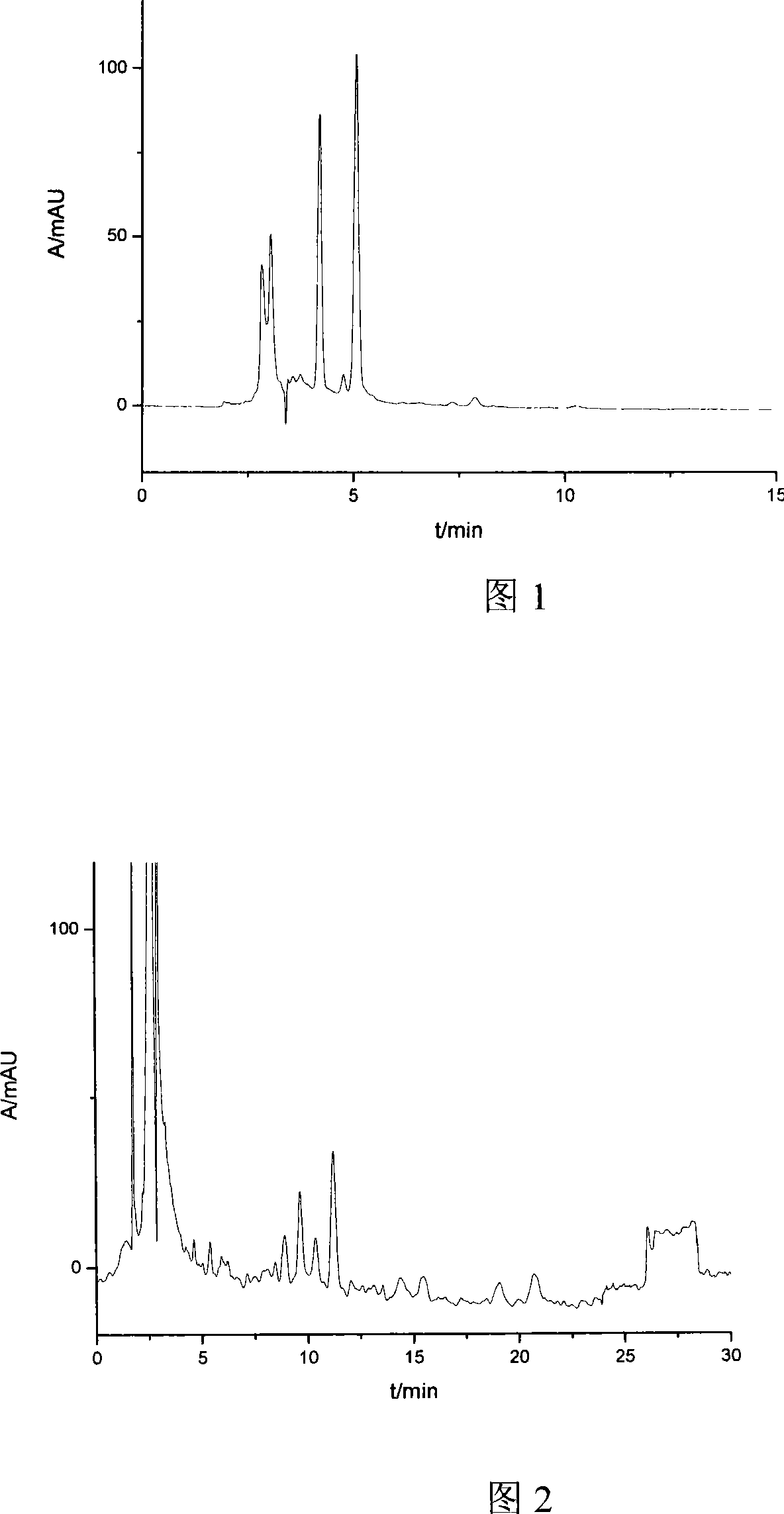

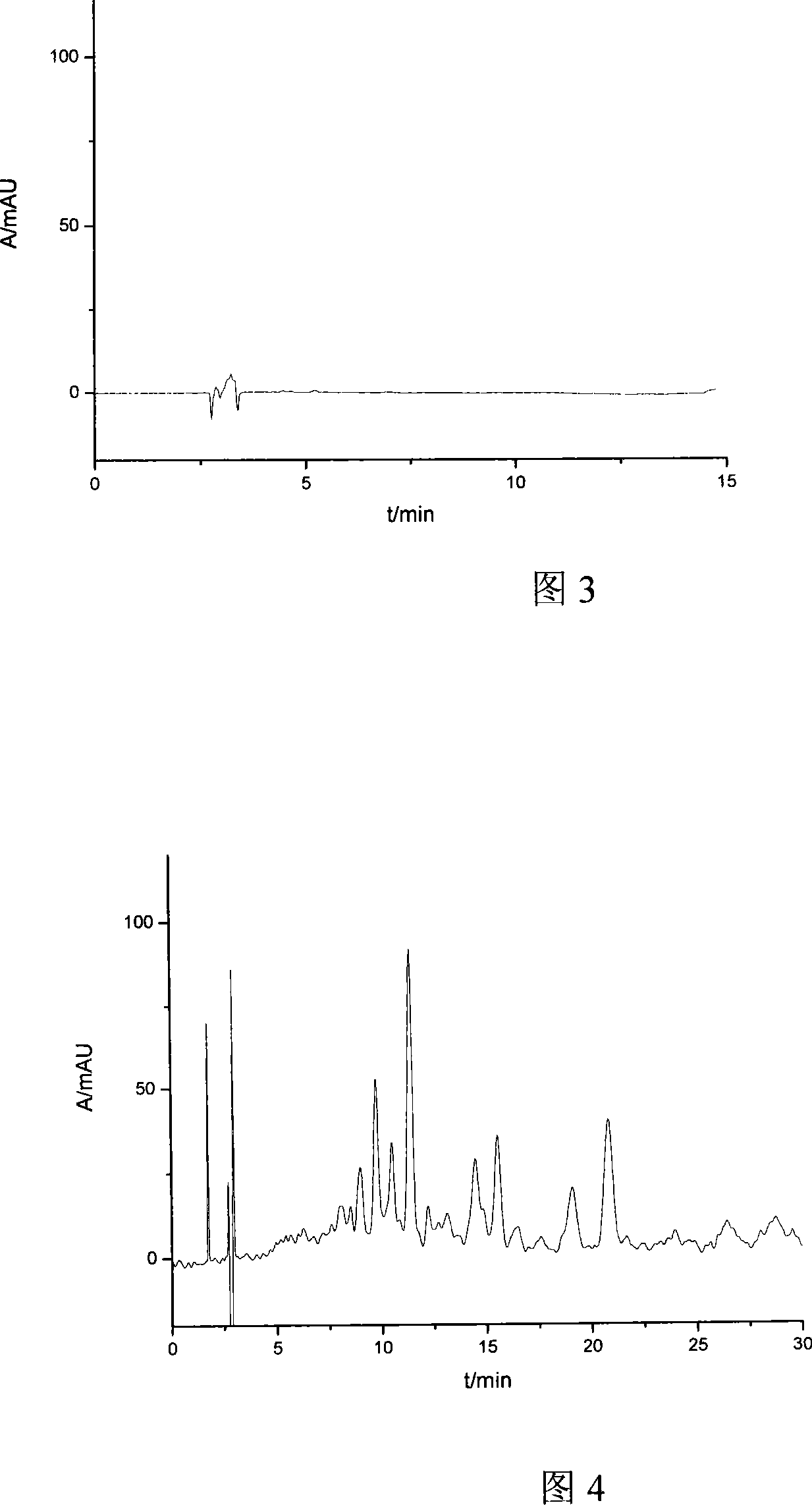

[0018] Pulverize the camellia cake with a pulverizer and pass it through an 80-mesh sieve. Take 20.000g of Camellia oleifera cake powder (paper package), 300ml of petroleum ether, degreasing by Soxhlet extraction, the temperature is 70 ℃, the heating time is 9h, and finally 18.3817g of degreasing powder is obtained (its chromatogram is shown in Figures 1 and 1). figure 2). Take 10g of defatted camellia oleifera cake and wrap it in paper and put it in a Soxhlet extractor; 1.5g of AB-8 macroporous adsorption resin, 200ml of 40% ethanol solution are placed in a round bottom flask, the heating temperature is 90 ℃, heating 6h. The macroporous adsorption resin was filtered, and the macroporous adsorption resin was placed in 45 ml of 60% ethanol solution at a temperature of 50° C., heated to reflux, and the reflux time was 7 h. 1.4354 g of tea saponin with a purity of 95.32% was obtained by spray drying (see Chromatograms 3 and 4).

[0019] The condition of the high performance li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com