Wave soldering bath

A welding bath and molten solder technology, which is used in welding equipment, tin feeding devices, electrical components, etc., can solve the problems of burns and charring of automatic brazing device wiring or workplace floors, and removal of labor and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

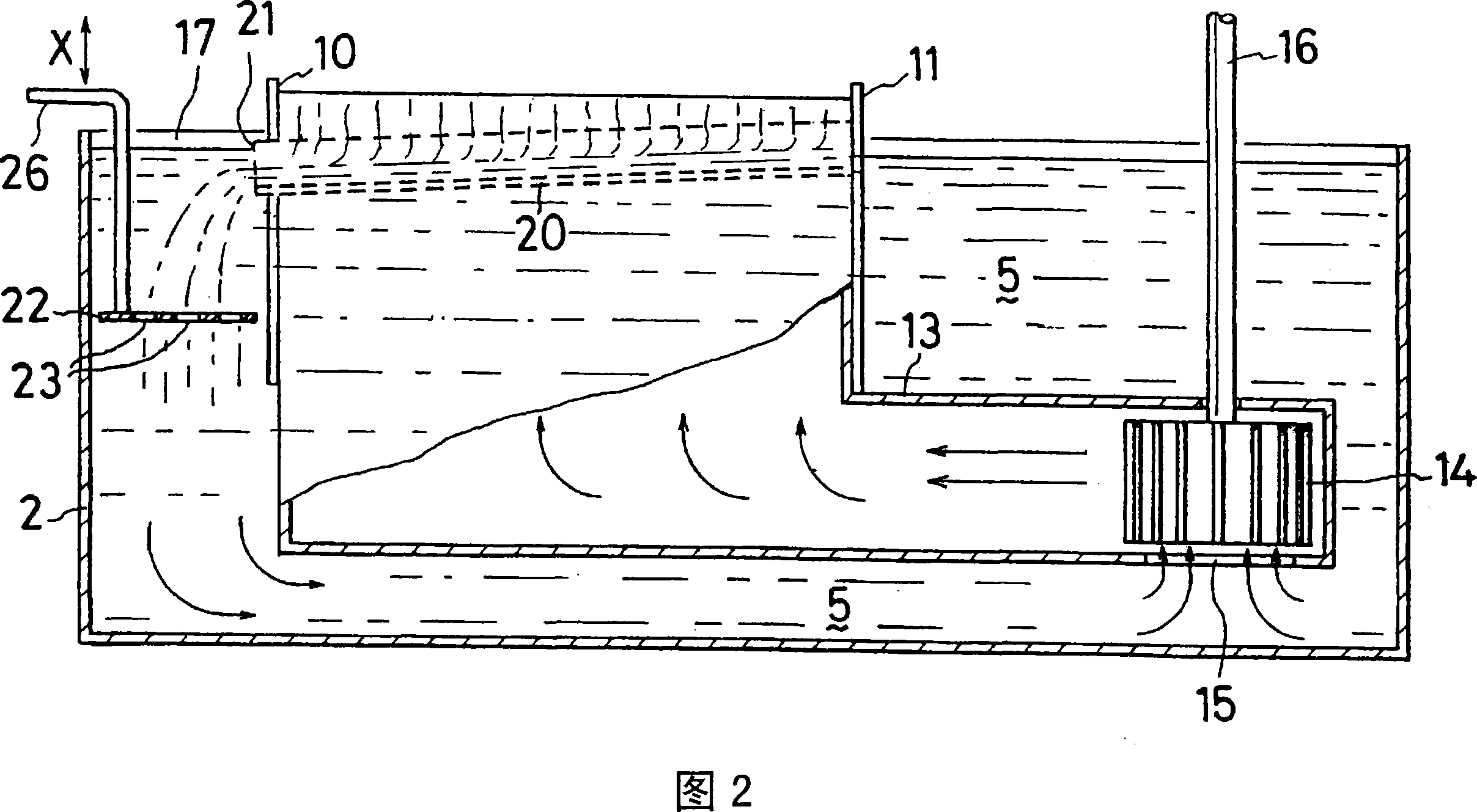

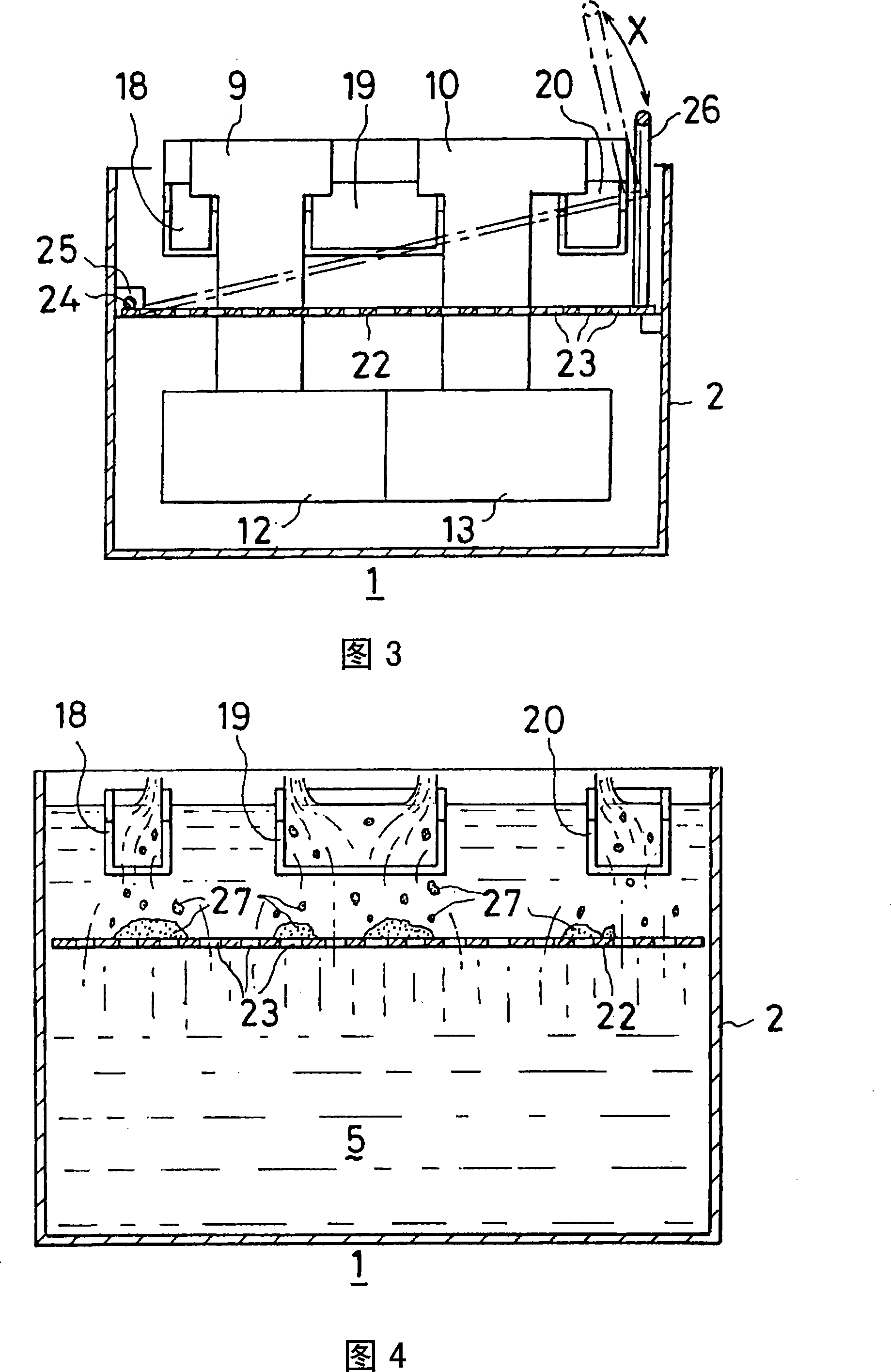

[0034]The installation position of the porous plate in the wave solder bath of the present invention, that is, the installation position from the liquid surface of molten solder is preferably 10 to 200 mm. When the distance between the installation position of the porous plate and the liquid surface of the molten solder is less than 10 mm, the molten solder flowing down from the groove is bounced by the porous plate to produce oxides, and the molten solder flowing down from the groove passes through the porous plate in a state of potential energy. The holes, together with the oxides, sink down and are sucked in by the jet pump. On the other hand, when the distance from the installation position of the perforated plate to the liquid surface is greater than 200 mm, the molten solder flowing down from the groove moves to the jet pump side before reaching the perforated plate, causing oxides to be sucked by the jet pump.

[0035] In addition, the hole diameter of the perforated pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com