Blast furnace distributor

A technology of distributor and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of complex structure and high price, and achieve the effect of stable transmission, compact structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

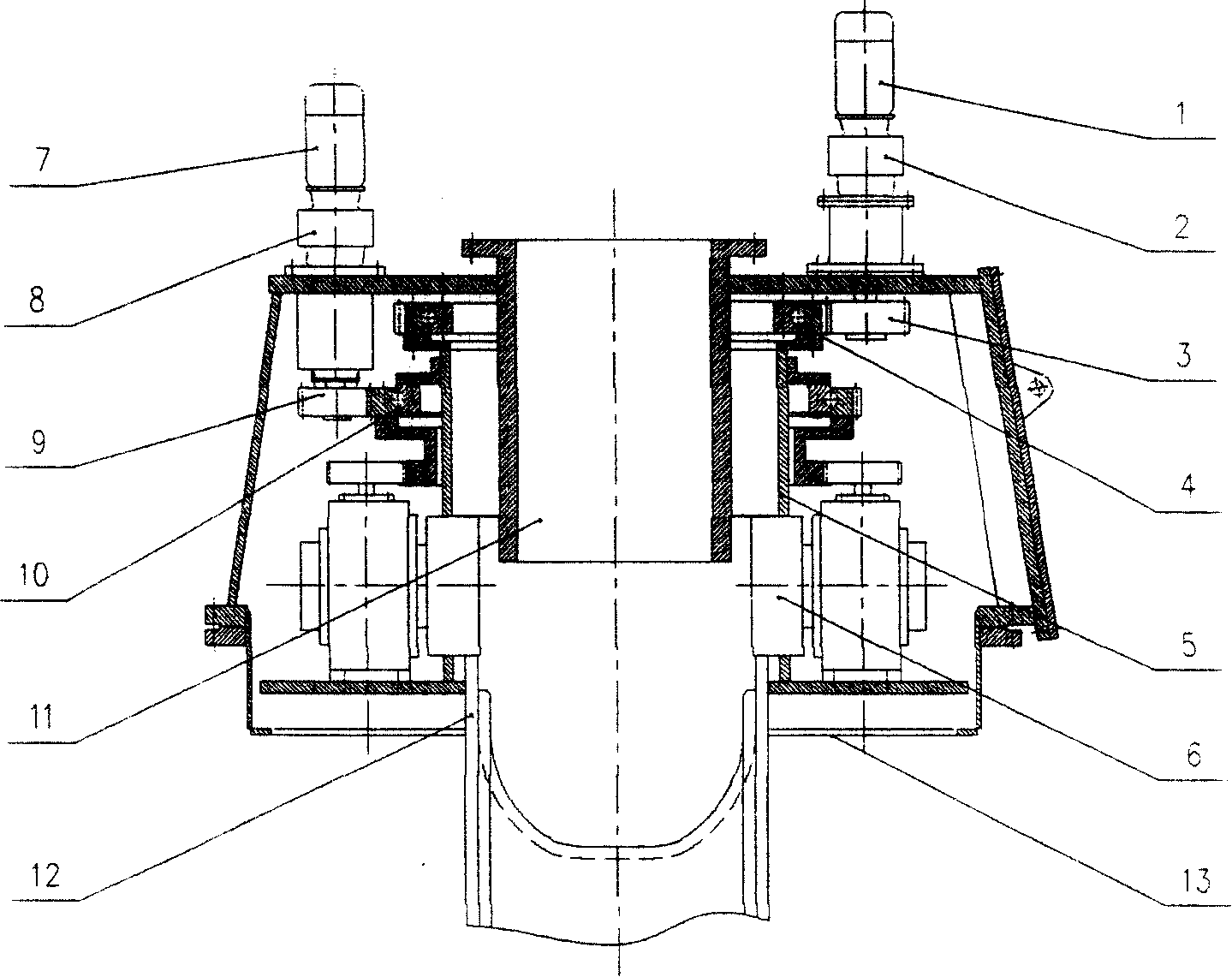

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] The distributor rotating motor 1 is supported on the casing 13 through the rotation reduction device 2, and the rotation gear 3 is sleeved on the output shaft of the reduction device 2. The inner ring of the slewing bearing 4 with the large gear is fixed on the box body 13, and the outer ring is connected with the cylinder disk 5 and meshed with the rotating gear 3. The trunnion 6 is supported on the cylinder disc 5 . The tilting motor 7 is supported on the casing 13 through the tilting deceleration device 8 , and the tilting gear 9 is sleeved on the outlet shaft of the deceleration device 8 and meshed with the large gear of the slewing support 10 . The inner ring of the slewing bearing 10 with a large gear is fixed on the cylinder plate 5, the outer ring is connected with the gear of the tilting mechanism, the gear of the tilting mechanism is sleeved on the trunnio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com