Method for substituting cement kiln fuel with garbage derived overtails

A waste-derived, cement kiln technology, applied in the energy field, can solve environmental pollution and other problems, and achieve the effect of increasing calorific value and saving coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

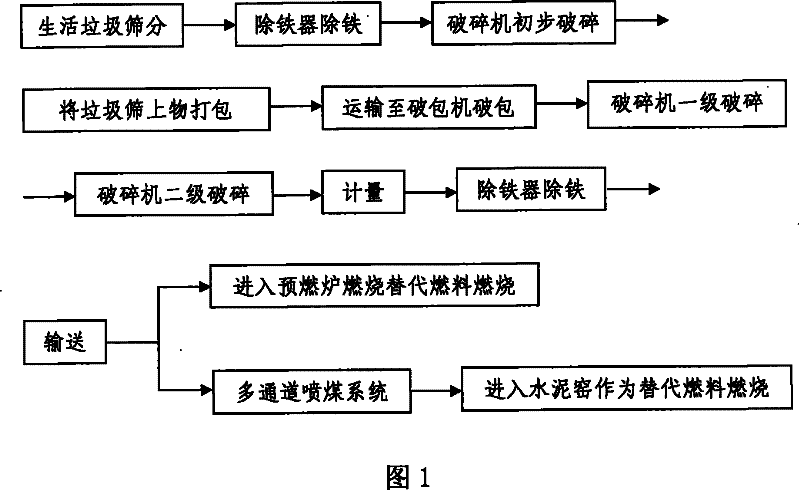

[0023] figure 1 Shown is the process flow of an embodiment of the present invention, first domestic garbage is sieved, the main components of the obtained garbage-derived oversize are: waste cotton fabrics, straw and plastics, and the garbage-derived oversize is removed Iron, primary crushed and packaged into cylindrical garbage bags weighing about 1.5 tons. After being transported to the factory area by a transport vehicle, they are lifted to the platform bag breaker in the pretreatment workshop, and then crushed by a crusher. In this embodiment, German-made The automatic crusher generally adopts two-stage or three-stage crushing. The particle size of the crushing is less than 60mm×60mm, preferably 50mm×40mm. It is stirred and mixed to make it uniform. Conveyor transport, one part is transported to the pre-combustion furnace for combustion, and the other part is sprayed into the cement kiln from the kiln head through the multi-channel coal injection pipe, so that the waste-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com