High-efficiency oxidation ditch biological sewage treatment method and system

A sewage biological treatment and oxidation ditch technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve sludge deposition, affect the performance of oxidation ditch sewage biological treatment system, and fully Low oxygen efficiency and other issues, to achieve the effect of high channel flow velocity, good mixing effect and reduced total energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

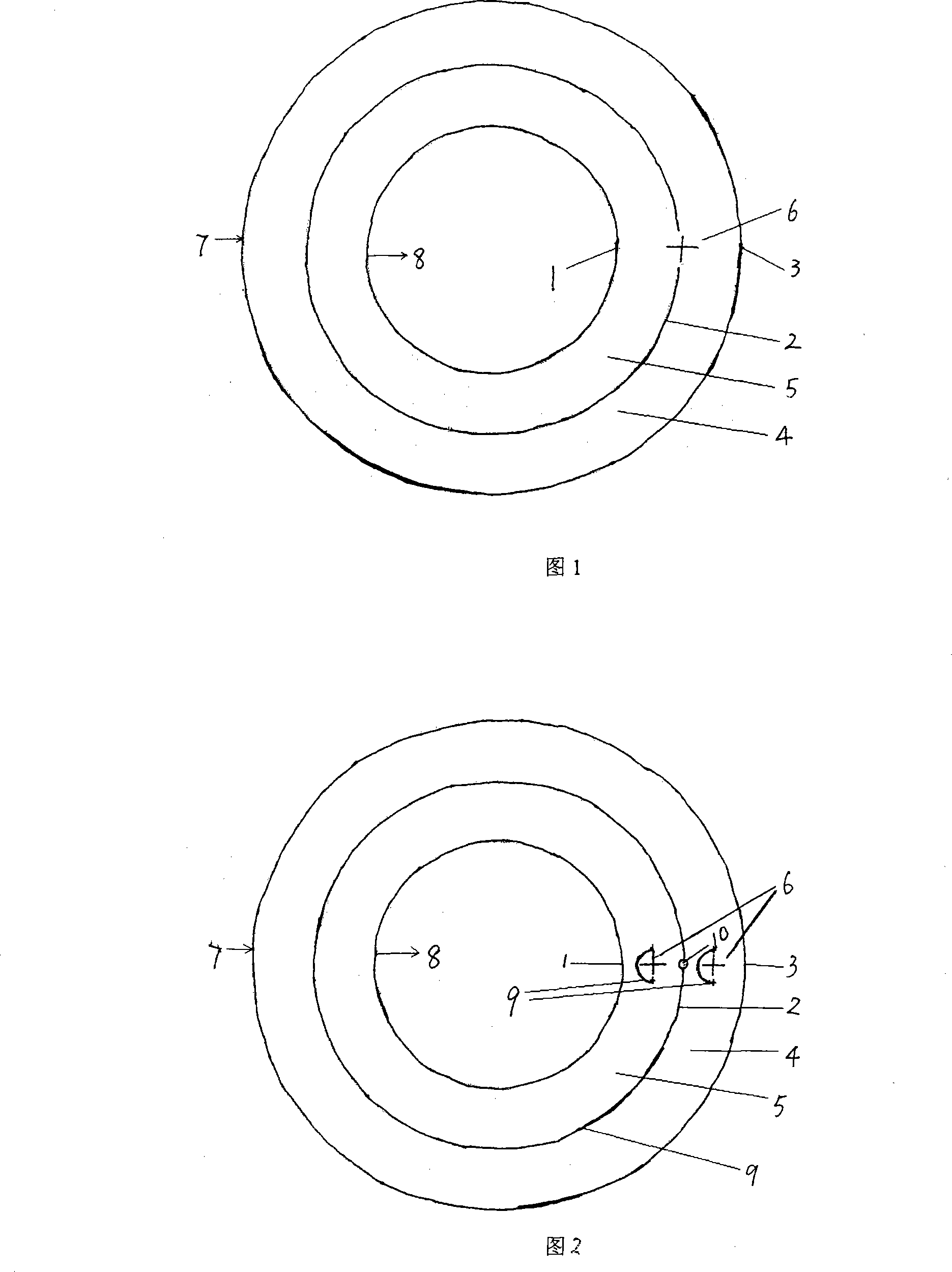

[0022] Embodiment 1: As shown in Figure 1, the annular oxidation ditch 4 and 5 surrounded by walls 1, 2 and 3, the low-speed surface aerator 6 is installed on the middle wall 2, and the mixed liquid of sewage and sludge passes through the water inlet 7 Enter the oxidation ditch 4, enter the oxidation ditch 5 through the aerator 6, and discharge through the water outlet 8. When the aerator is working, it rotates clockwise to provide dissolved oxygen, and at the same time pushes the water in the oxidation ditch 4 to flow clockwise. The water flows counterclockwise. Complete the sewage aerobic treatment process.

Embodiment 2

[0023] Embodiment 2: as shown in Figure 2, the ring-shaped oxidation ditch 4 and 5 that are surrounded by wall 1, 2 and 3, aerator 6 is installed in the middle of oxidation ditch 4 and 5, deflector 9 is equipped with on the periphery, sewage and The sludge mixture enters the oxidation ditch 4 through the water inlet 7, enters the oxidation ditch 5 through the hole 10 in the middle partition wall, and is sent out through the water outlet 8. When the aerator 6 is working, it rotates clockwise to provide dissolved oxygen and promote the oxidation ditch The water flow in 4 and 5 flows clockwise, and the sewage aerobic treatment process is completed in the oxidation ditch.

example example 3

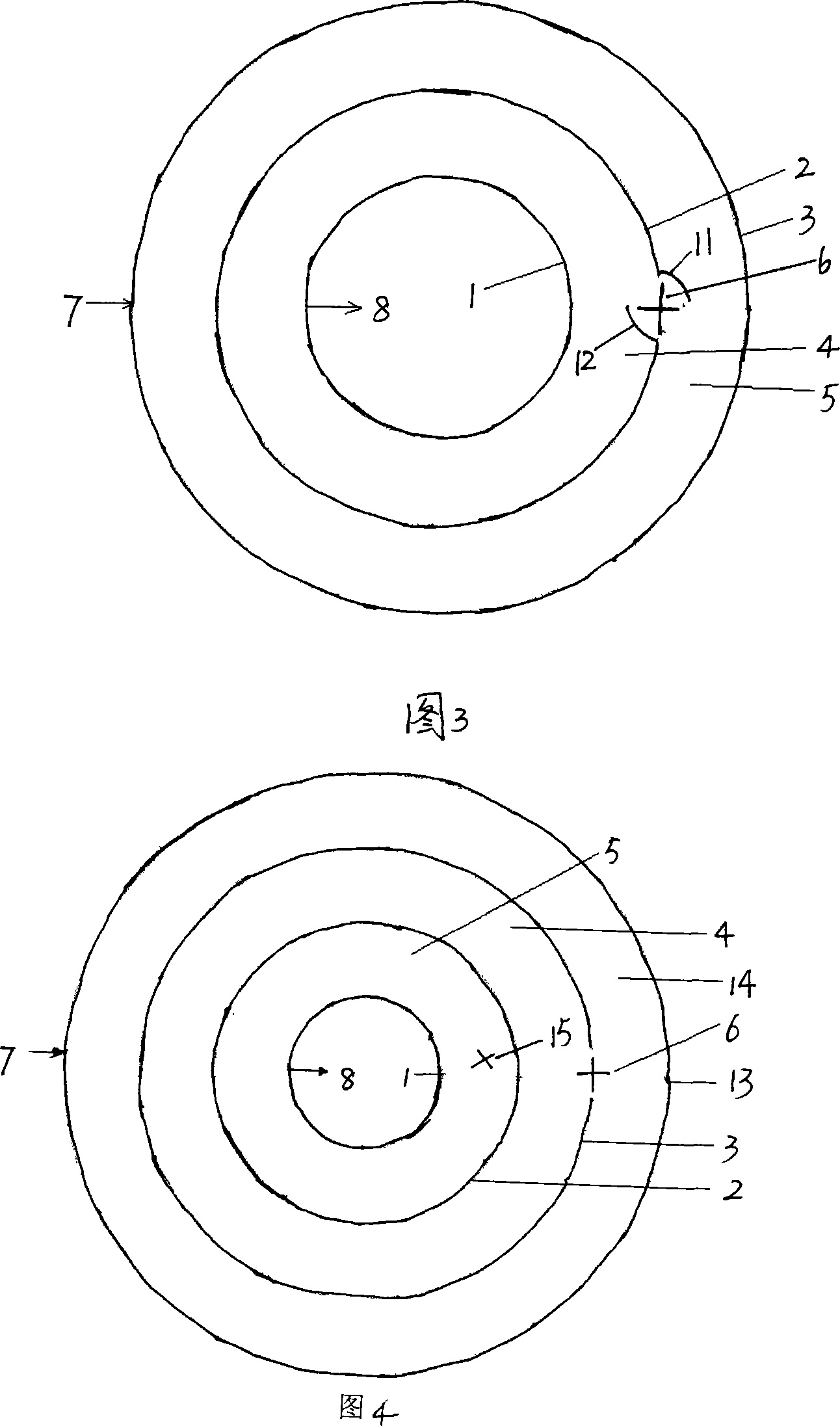

[0024] Example 3: As shown in Figure 3 and Figure 4, the ring-shaped oxidation ditch 4 and 5 surrounded by walls 1, 2 and 3, the aerator 6 is installed on the middle wall 2, and the mixed liquid of sewage and sludge passes through the water inlet 7 enters the oxidation ditch 4, enters the oxidation ditch 5 through the aerator 6, and sends out through the water outlet 8. When the aerator is working, it rotates clockwise to provide dissolved oxygen, and at the same time promotes the water flow in the oxidation ditch 5 to flow clockwise, and the oxidation ditch 4 The inner water flows counterclockwise. There are two 90-degree arc deflectors 11 and 12 installed around the aerator, which are respectively installed on the two oxidation ditch. The height of the deflector is equal to the height of the impeller of the aerator. level with the water. Add two so that when the water flow leaves the aerator, the flow direction is directed to the flow direction of the channel, increasing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com