Releasing mechanism and leveling apparatus

A release mechanism and processing device technology, which is applied in the field of correction processing devices, can solve problems such as difficult opening movements, large-scale and complicated devices, and achieve the effects of improving the working environment and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

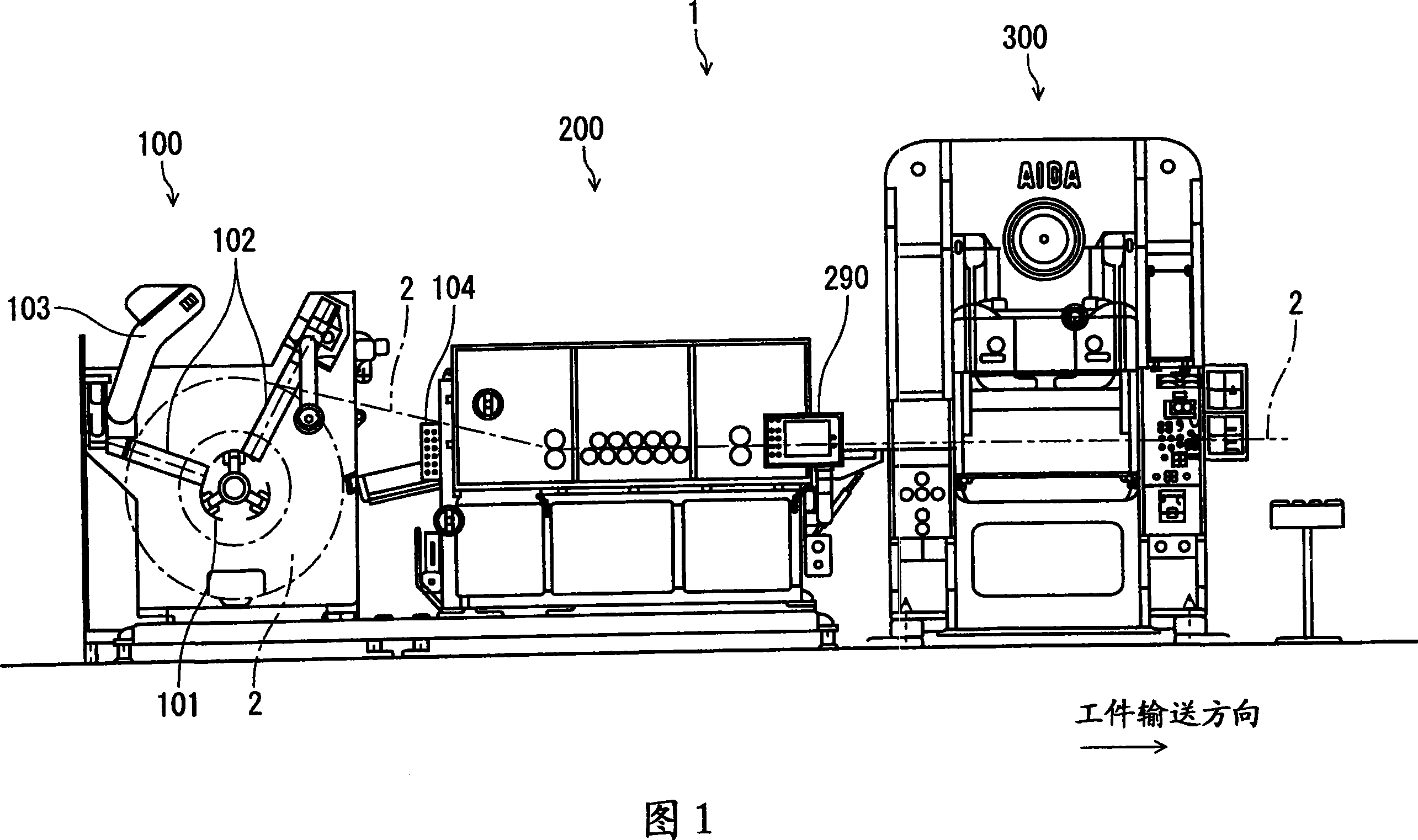

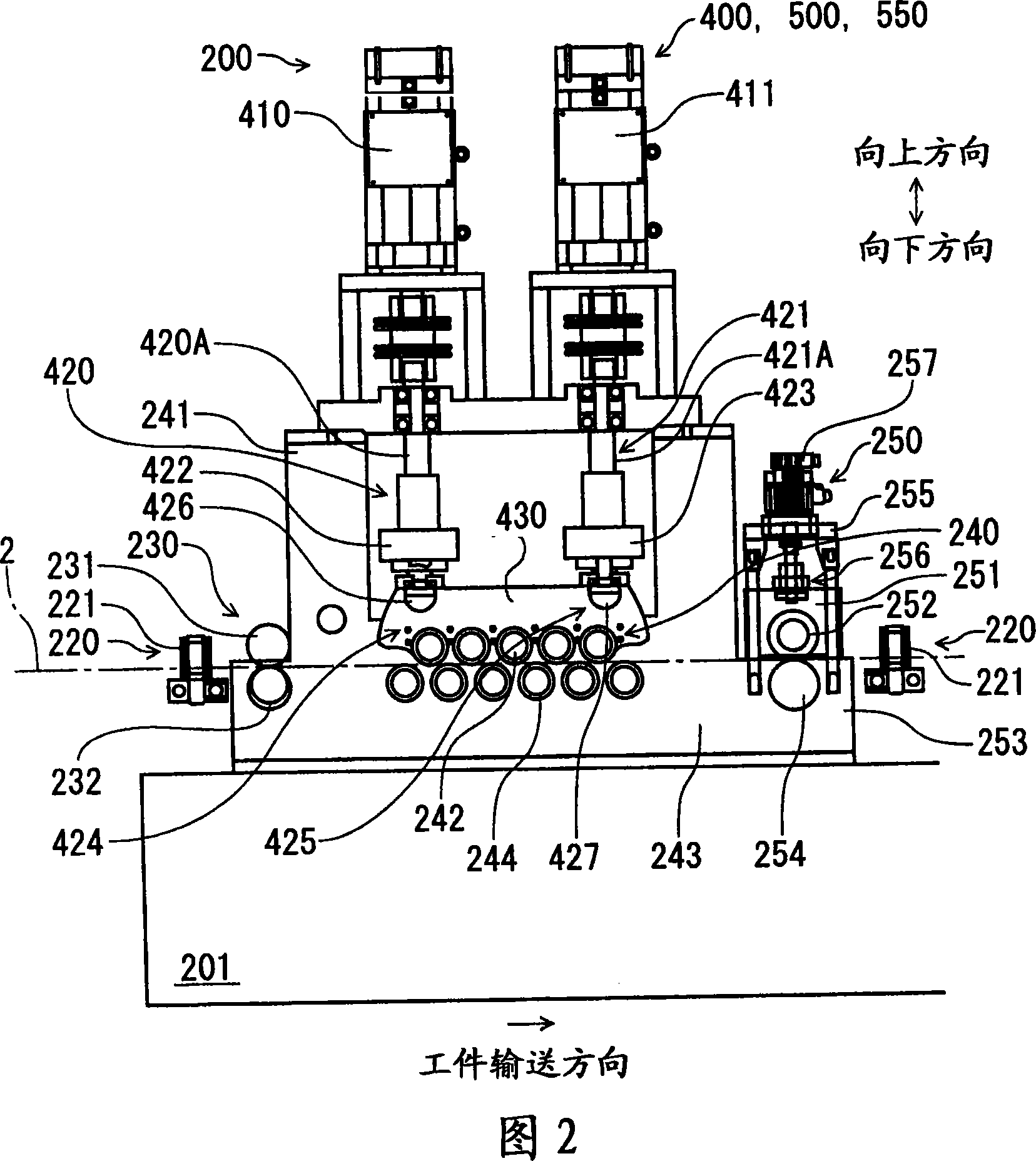

[0054] The automatic punching device 1 in the first embodiment of the present invention, as shown in FIG. The workpiece 2 sent out from the above-mentioned unwinding unit 100 is sent out to the leveling feeding unit 200 of the punching unit 300 downstream of the processing process while correcting deformation such as warping of the workpiece 2, and the above-mentioned leveling feeding unit The stamping section 300 that performs stamping on the workpiece 2 delivered from the section 200.

[0055] The above-mentioned unwinding unit 100 is configured to include: a drum 101, which supports the long workpiece 2 as a coil while being rotated by a motor or the like, and sends the workpiece 2 to the leveling and feeding unit in a predetermined amount one by one. 200; the side guide part 102, which supports the workpiece 2 wound on the drum 101 from both sides so as to prevent the coil from collapsing; and the coil pressing part 103 (holding part), which is used to prevent the And whe...

no. 2 approach

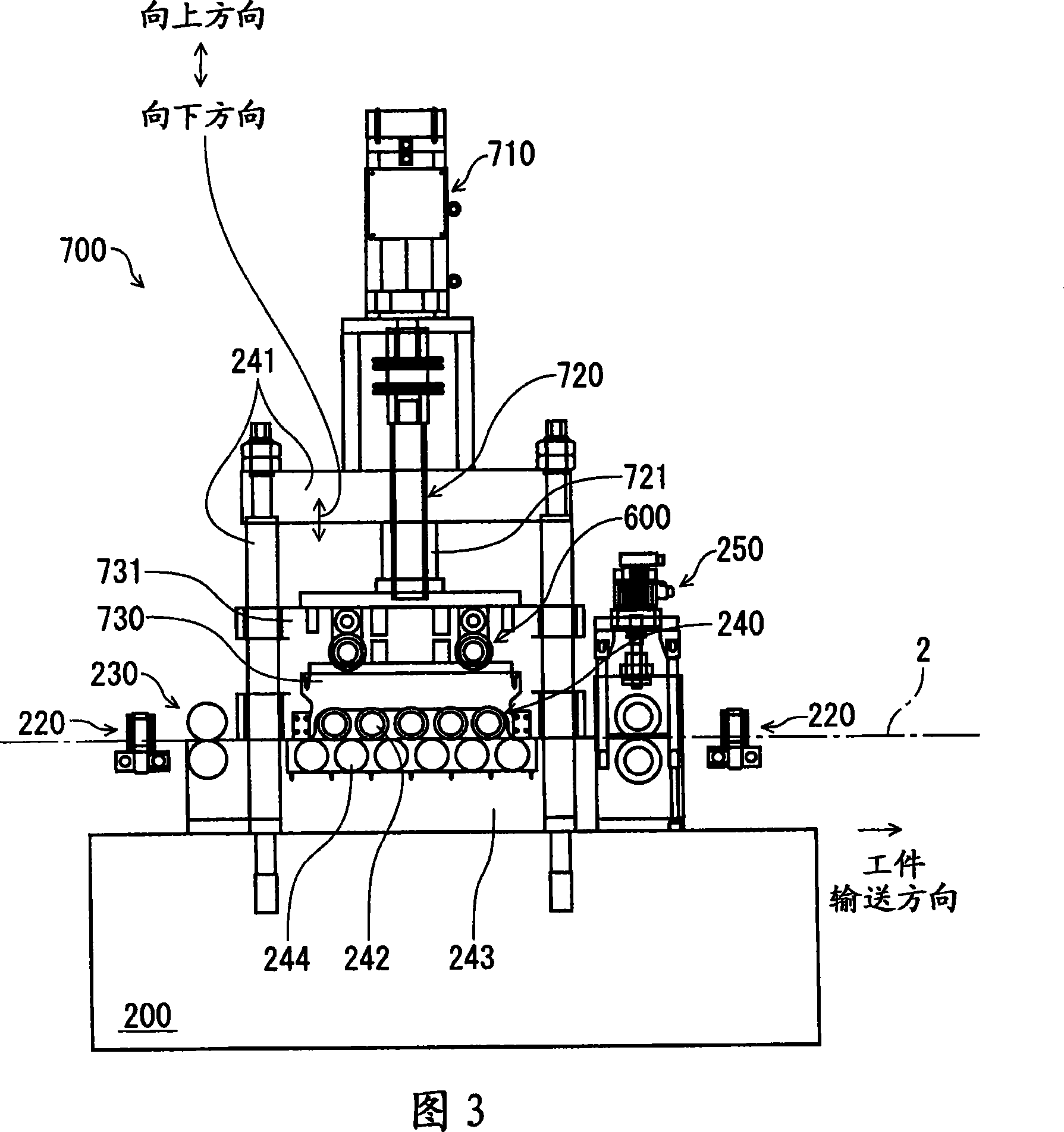

[0110] Next, a second embodiment of the present invention will be described in detail with reference to FIGS. 3 and 4 .

[0111] In addition, since the second embodiment differs from the first embodiment only in the structure of the leveling and feeding unit 700, the leveling and feeding unit 700 will be described, and the same elements will be given the same reference numerals, and detailed description will be omitted. .

[0112] The leveling feed unit 700 of this embodiment is configured to include: a servo motor 710 , a ball screw unit 720 connected to the servo motor 710 , and an upper work roll support member supported by the ball screw unit 720 via a support member 731 . (surface-side work roll support member) 730 .

[0113] The ball screw unit 720 converts the rotational motion of the servo motor 710 mounted on the upper frame 241 substantially integrally with the main body frame 201 into the reciprocating motion of the output member 721 mounted on the on the support ...

no. 3 approach

[0143] Next, a third embodiment of the present invention will be described in detail with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same element as 1st, 2nd embodiment, and detailed description is abbreviate|omitted.

[0144] As shown in FIG. 6 , the automatic punching device 1 of this embodiment is configured to include: an unwinding section 100 that feeds a coiled workpiece 2 to a leveling and feeding section 200 downstream of the processing process; The workpiece 2 sent out from 100, the workpiece 2 is sent out to the leveling feeding part 1200 of the punching part 300 downstream of the processing process while correcting the deformation such as warping of the workpiece 2, and the workpiece sent out from the above-mentioned leveling feeding part 200 2. A press part 300 for performing press work.

[0145] The above-mentioned unwinding unit 100 includes: while supporting the long workpiece 2 wound into a coil shape, the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com