Arrangement for regulating pressure of scratch board in automatic silk screen dyeing machine

A technology of pressure regulation and scraper, which is applied to screen printing machines, printing machines, rotary printing machines, etc., and can solve problems such as motor failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

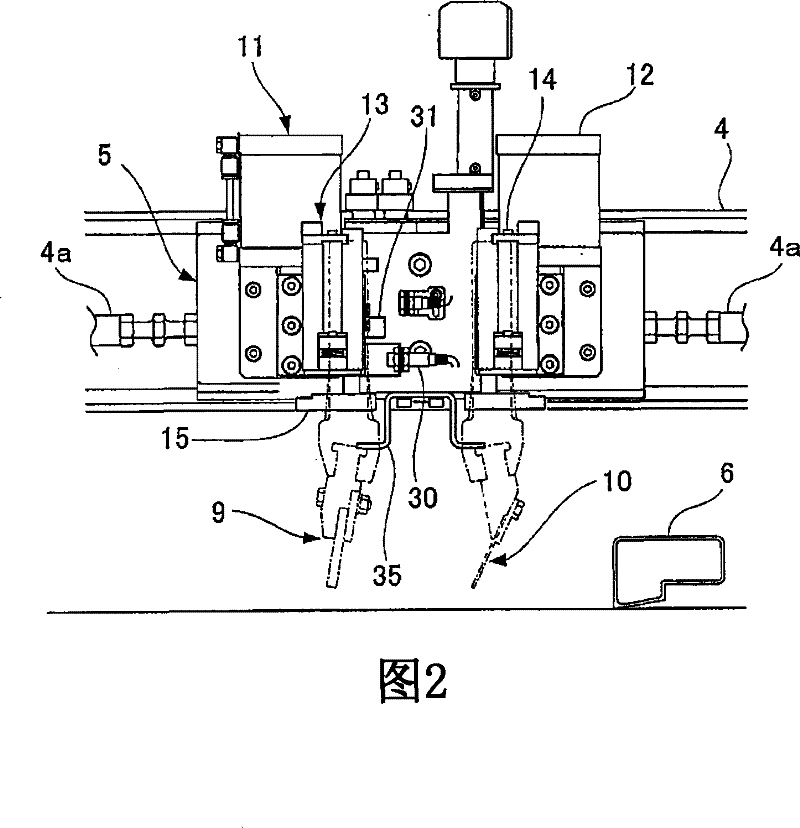

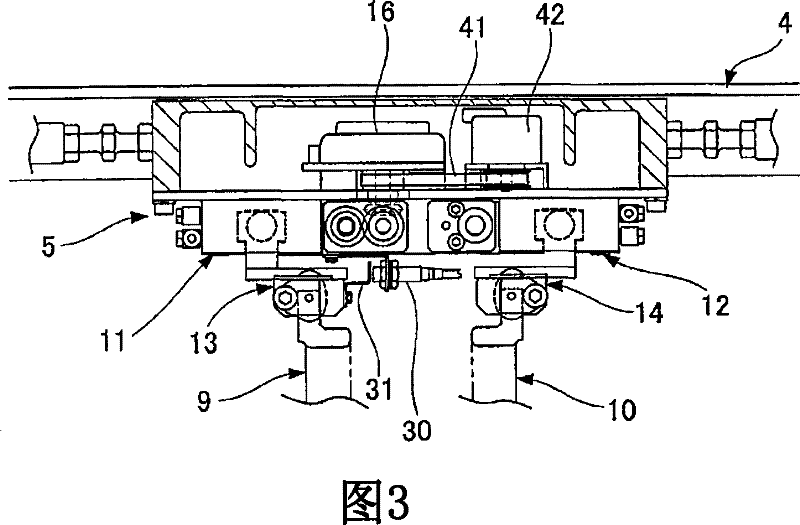

[0026] Refer to the following Figure 1-14 Embodiments of the present invention will be described.

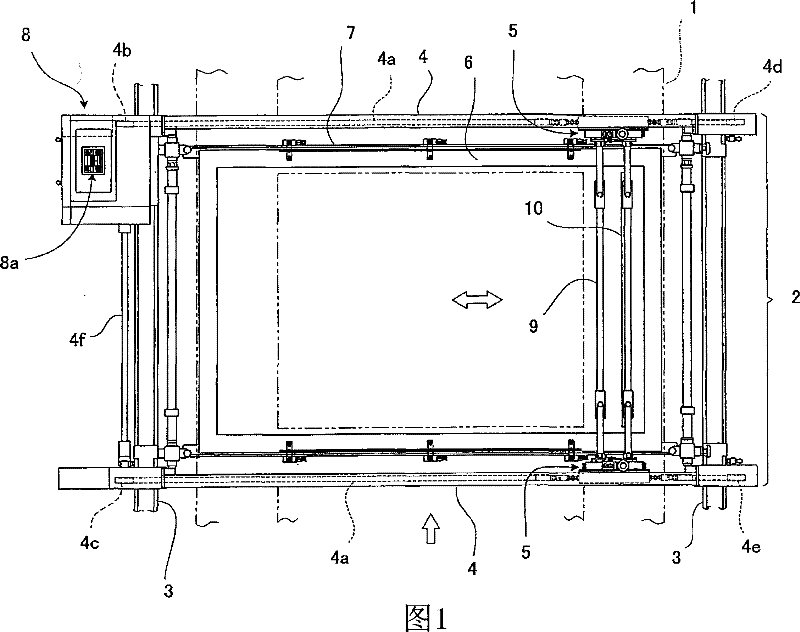

[0027] figure 1 It is a plan view showing the printing and dyeing unit of the automatic screen printing machine. The automatic screen printing and dyeing machine is equipped with a printing and dyeing unit 2 on an endless belt 1 . exist figure 1 Although only one printing and dyeing unit 2 is shown in the figure, in practice, a plurality of printing and dyeing units 2 may be arranged along the longitudinal direction of the endless belt. The printing and dyeing unit 2 includes guide frames 4 , 4 arranged on the machine table 3 and scraper supports 5 , 5 freely movable supported by the guide frames 4 , 4 . Furthermore, a fixing member 7 for supporting the screen tension frame 6 is attached to the guide frames 4 , 4 .

[0028] The scraper brackets 5, 5 are connected to the timing belts 4a, 4a arranged in the guide frames 4, 4. Timing belts 4a, 4a are wound around timing pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com