Montmorillonite/Ymolecular sieve composite material and preparation method thereof

A composite material and molecular sieve technology, which is applied in the field of montmorillonite/Y molecular sieve composite material and its preparation, can solve the problems of affecting catalytic performance, prone to sintering, etc., and achieves good hydrothermal stability, low cost, high thermal stability and high thermal stability. The effect of hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

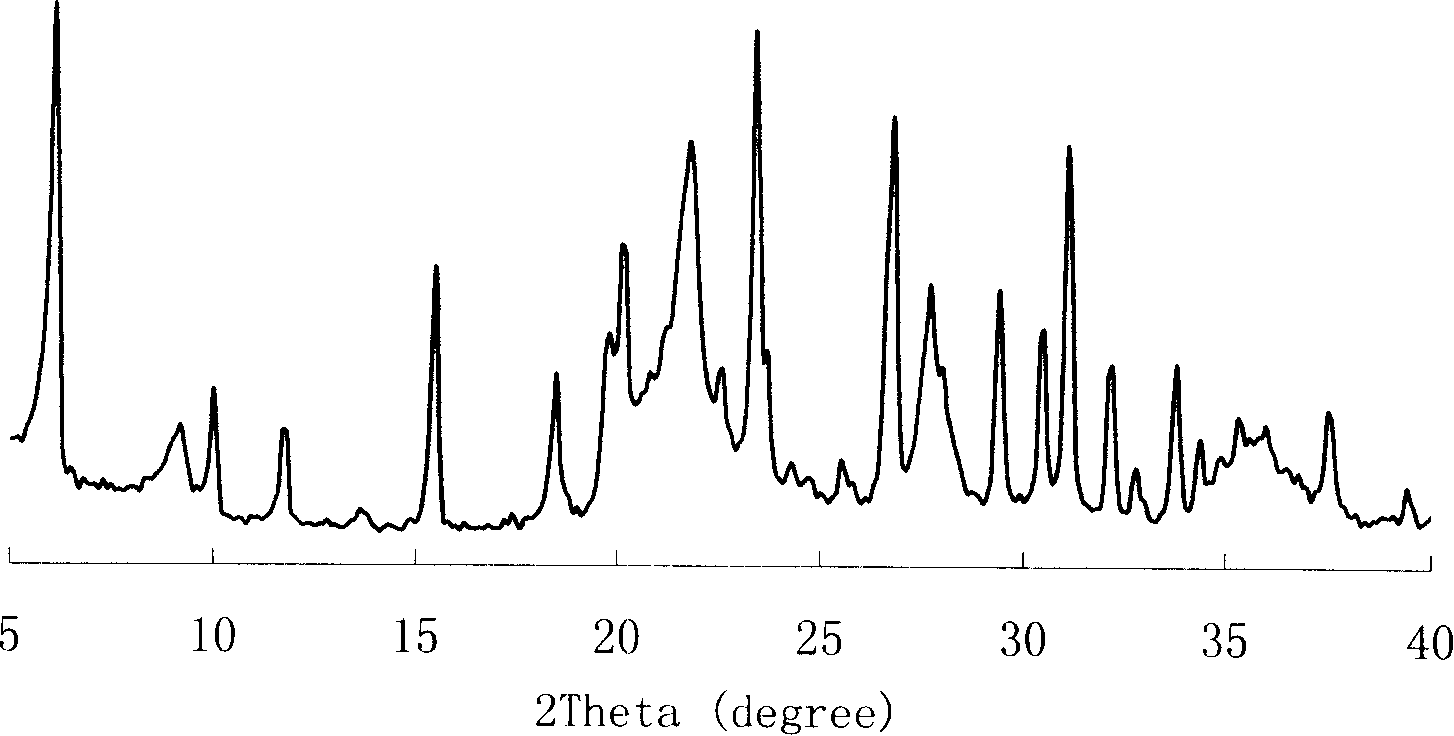

Image

Examples

preparation example Construction

[0023] (2) The preparation of Y molecular sieve gel can specifically take the following methods:

[0024] Silicon source, aluminum source, sodium hydroxide and water according to (2 ~ 10) SiO 2 :Al 2 o 3 : (1~3)Na 2 O:(100~600)H 2 The molar ratio of O is mixed at room temperature and under mechanical stirring conditions, and the stirring is continued until the raw materials are evenly mixed to obtain a molecular sieve gel; the silicon source is white carbon black or silica sol; the aluminum source is sodium metaaluminate or hydroxide Aluminum, preferably sodium metaaluminate.

[0025] (3) Add the directing agent to the molecular sieve gel prepared in step (2), the amount of the directing agent accounts for 2 to 10v% of the volume of the molecular sieve gel, stir to obtain a reaction gel, then add montmorillonite microspheres , the weight ratio of montmorillonite microspheres and reaction gel is (30~70): (70~30), preferably (50~60): (50~40), stirring at room temperature fo...

Embodiment 1

[0036] (1) Preparation of the guiding agent: 1) Weigh 4.07g of sodium hydroxide and 2.09g of sodium aluminate, dissolve them in 19.95g of distilled water, and mix them evenly with electromagnetic stirring. 2) Mix the above solution with 22.72 g of sodium silicate solution. 3) After the above solution was magnetically stirred for 0.5 hours, it was put into an Erlenmeyer flask, sealed and aged at 35° C. for 96 hours to make a directing agent.

[0037] (2) Synthesis of Y molecular sieve and its growth on montmorillonite microspheres. 1) Take 130.97g of distilled water, dissolve 0.14g of sodium hydroxide and 13.09g of sodium aluminate, and stir until completely dissolved. 2) Mix the above solution with 142.43g of sodium silicate and stir vigorously until the gel is uniformly formed to obtain silica-alumina gel. 3) Add 40ml of directing agent to the silica-alumina gel, then add 30g of montmorillonite microspheres, and stir at room temperature for 0.5 hours. Hydrothermal crystall...

Embodiment 2

[0040] (1) Preparation of the guiding agent: 1) Weigh 4.07g of sodium hydroxide and 2.09g of sodium aluminate, dissolve them in 19.95g of distilled water, and mix them evenly with electromagnetic stirring. 2) Mix the above solution with 22.72 g of sodium silicate solution. 3) After the above solution was magnetically stirred for 0.5 hours, it was put into an Erlenmeyer flask, sealed and aged at 35° C. for 72 hours to make a directing agent.

[0041] (2) Synthesis of Y molecular sieve and its growth on montmorillonite microspheres. 1) Take 130.97g of distilled water, dissolve 0.14g of sodium hydroxide and 13.09g of sodium aluminate, and stir until completely dissolved. 2) Mix the above solution with 142.43g of sodium silicate and stir vigorously until the gel is uniformly formed to obtain silica-alumina gel. 3) Add 40ml of directing agent to the above-mentioned silica-alumina gel, then add 60g of montmorillonite microspheres, stir at room temperature for 0.5 hours, and conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com