Profibus DP and CAN bus combination communication method applied in cigarette machine

A technology of CAN bus and communication method, applied in the field of industrial control, can solve the problems such as the inability to realize the logic control function of the cigarette machine, and achieve the effect of enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

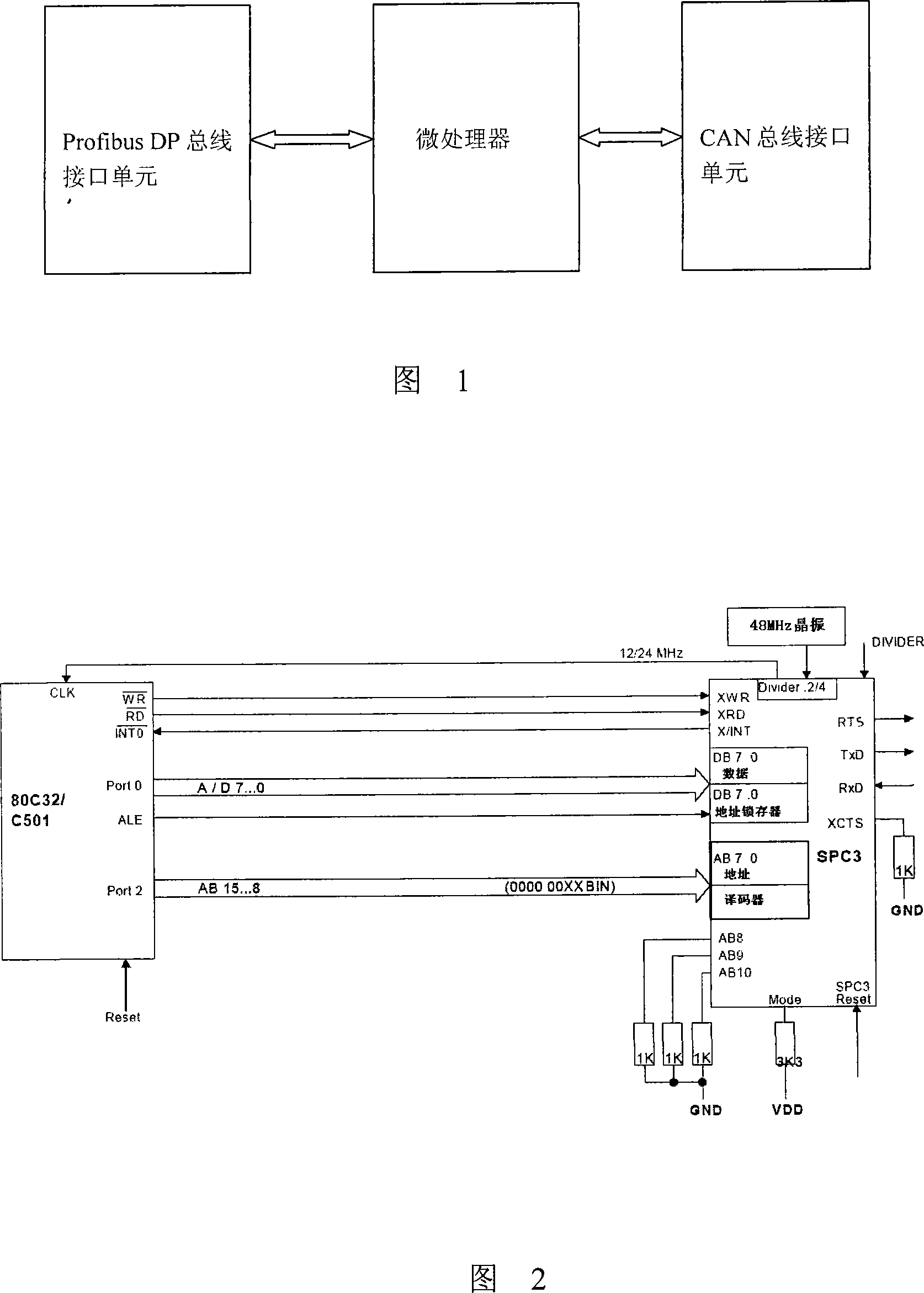

[0025] In this embodiment, as shown in FIG. 1 , the Profibus DP bus interface unit is used as a Profibus DP slave station to exchange bus data. The content of the data is directly transmitted to the microprocessor through the Profibus DP bus, and the similar CAN bus interface unit as a node on the CAN bus realizes the data exchange on the CAN bus and directly transmits the data content to the microprocessor.

[0026] In the practical application of the present invention, after the microprocessor obtains the data on both sides, it is not simply to realize the data exchange on both sides through a certain protocol, but to process and realize the data on both sides respectively and make the data on both sides can be connected. On the other hand, the microprocessor can also directly execute logic actions based on the data obtained on the two buses, or return the logic information or data on the microprocessor to both sides.

[0027] In this embodiment, the programmable logic contr...

Embodiment 2

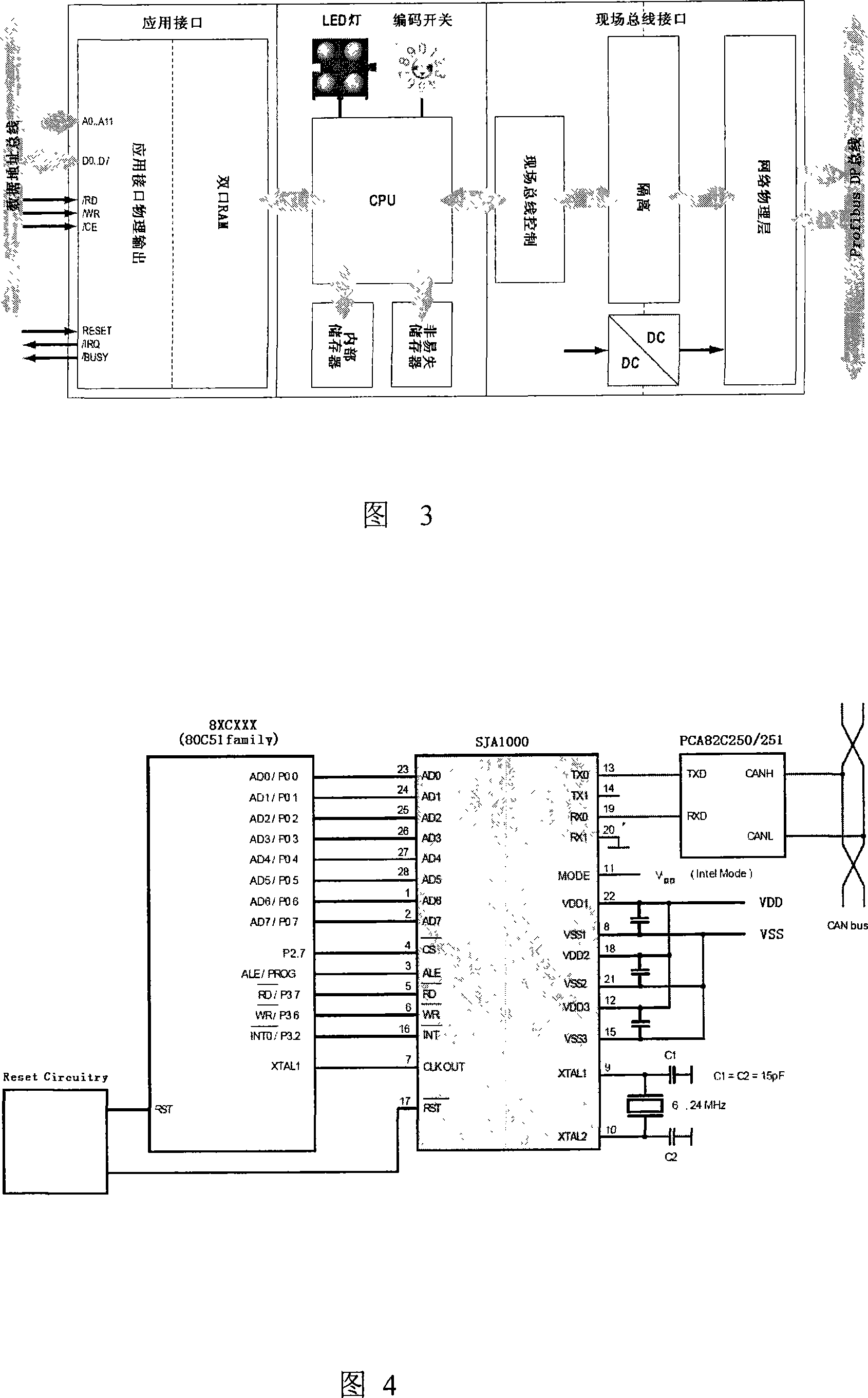

[0032]In the present embodiment, as shown in Figure 3, the connection of "Profibus DP bus interface unit" and the microprocessor can use the Profibus DP slave station module that provides the data address line interface as the connection mode, that is, the SPC3 data address line and The connection mode of the microprocessor, the box in the figure is a module integrating Profibus DP slave function, the address lines A0 to A11 and data lines D0 to D7 on one side of Anybus are connected to the address data line of the CPU They are respectively connected to the read, write and chip select pins of the CPU; the other side of the Anybus is directly connected to the Profibus DP bus.

[0033] In this embodiment, the microprocessor itself has a CAN function, and the microprocessor only needs to be simply connected to the CAN level chip, which is 82C250, and the device can be directly connected to the CAN bus. The microprocessor in this embodiment is LPC2294, and its CPU itself has inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com