Granule graininess, concentration and density measuring method and device

A technology for density measurement and particles, which is applied in measuring devices, particle and sedimentation analysis, particle size analysis, etc. It can solve problems such as difficulty in ensuring accurate results, inability to obtain particle size distribution, and poor versatility of measurement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

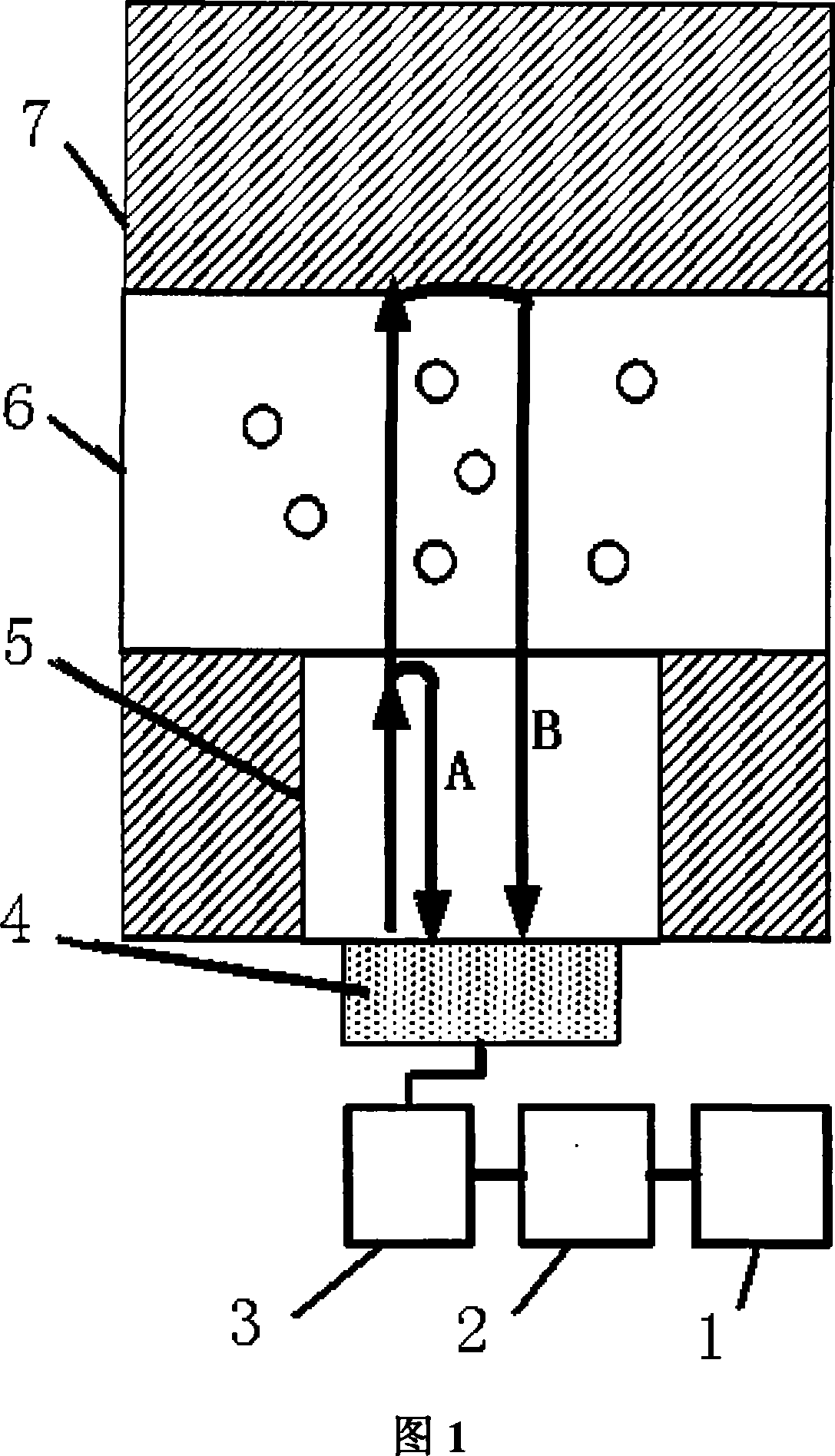

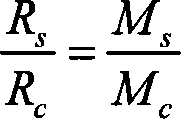

[0042] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods, structures and similar changes of the present invention should be included in the scope of protection of the present invention.

[0043] The working principle of particle size, concentration and density measurement (method) of the embodiment of the present invention:

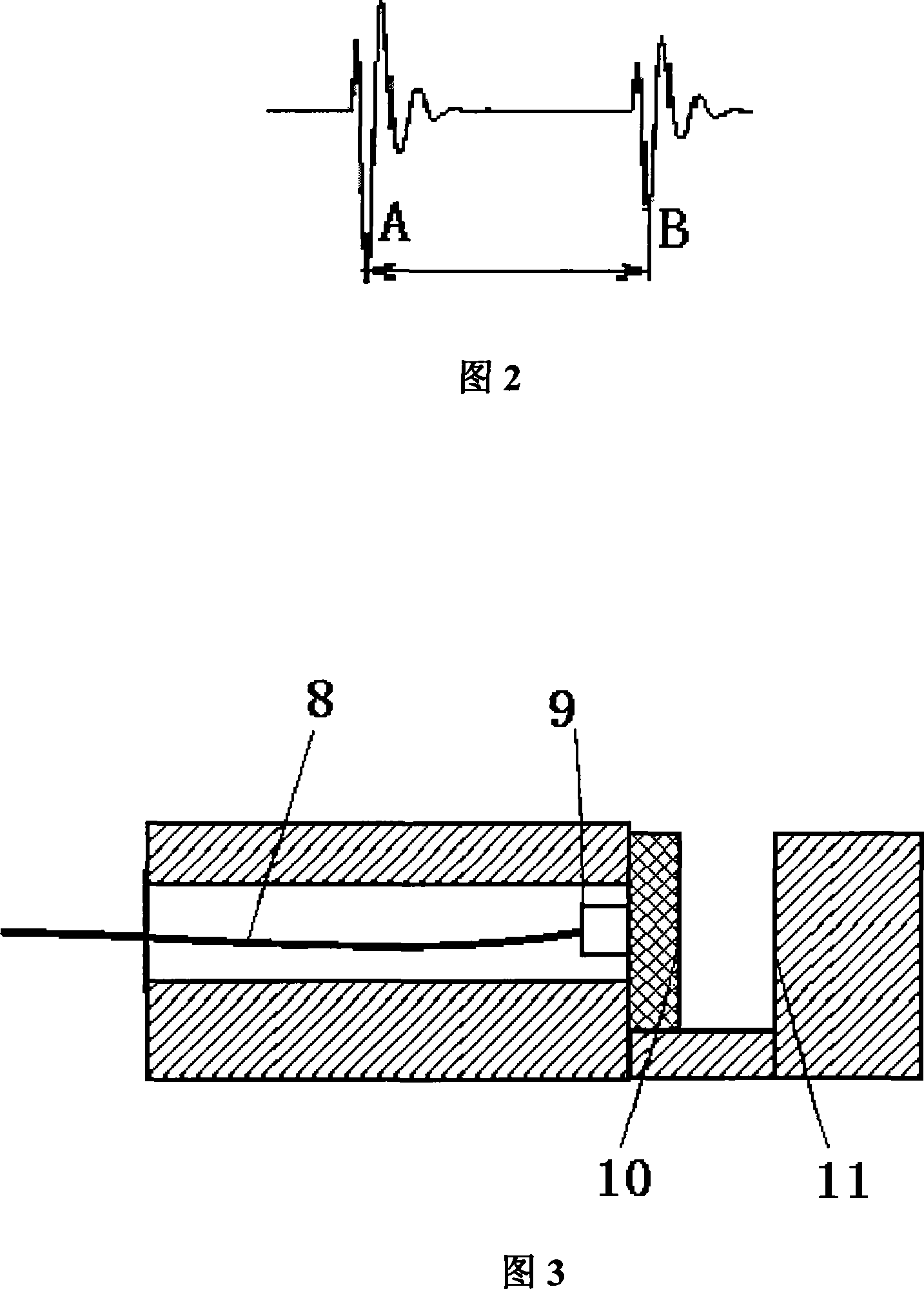

[0044] ①Measurement of reflection coefficient and acoustic characteristic impedance: By comparing the reflection signals of the sample to be tested and the calibration material, when samples or calibration materials are placed in the measurement areas, there are different reflection coefficients between the buffer plate and the interface of the measurement area. Comparing this with the following relationship:

[0045] R s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com