Wall thermal insulation structure and construction method thereof

A technology for walls and thermal insulation blocks, applied to walls, building components, building structures, etc., can solve problems such as delamination, hollowing, cracking, etc., and achieve the effect of strong comprehensive technical advantages and simple and practical construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

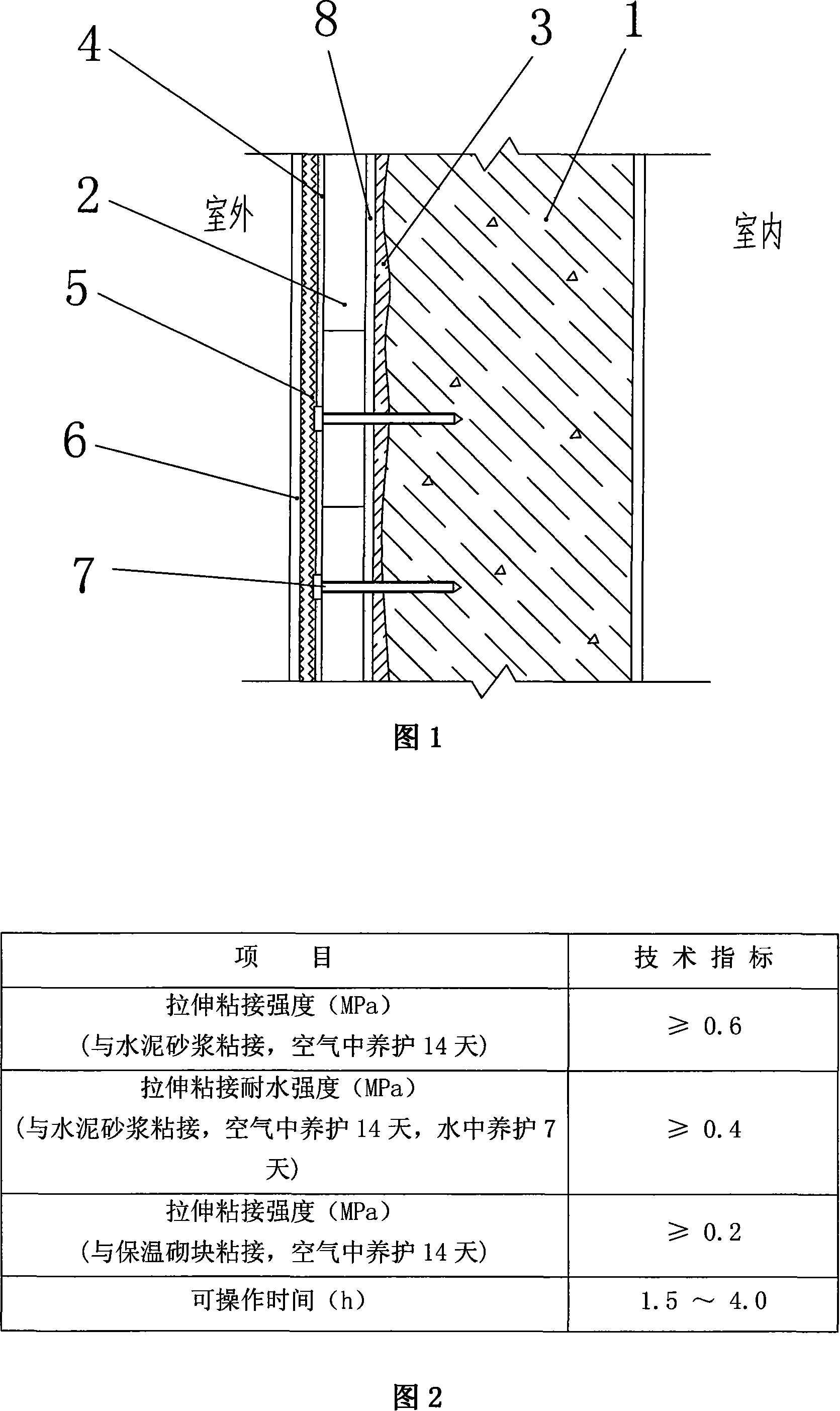

[0015] The wall thermal insulation structure of the present invention comprises a base wall 1, an air-entraining thermal insulation layer 2 is pasted on the outer surface of the base wall 1, and an anti-crack protective layer 5 is compounded on the outer surface of the air-entraining thermal insulation layer.

[0016] In order to ensure the smoothness of the surface after pasting the air-entraining thermal insulation layer, the base wall includes a cement mortar leveling layer 3 .

[0017] In order to enhance the strength of the anti-crack protection layer 5, the anti-crack protection layer 5 is composed of mesh cloth, anti-crack mortar or is composed of mesh cloth and plastering putty, and an anti-crack protection layer is provided between the thermal insulation layer 2 and the anti-crack protection layer 5. The interface agent layer 4 with the function of bonding and isolating, the interface agent layer 4 is an air-entrained concrete interface agent layer, which is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com