Chlorinated polyvinyl chloride DN400 conduction through pipe fitting once injection moulding technique and device thereof

An injection molding process, a technology of chlorinated polyvinyl chloride, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of long pre-molding time, difficult to control the friction heat of the screw, instability, etc., to improve the friction temperature High speed, stable rotation speed, and the effect of reducing frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

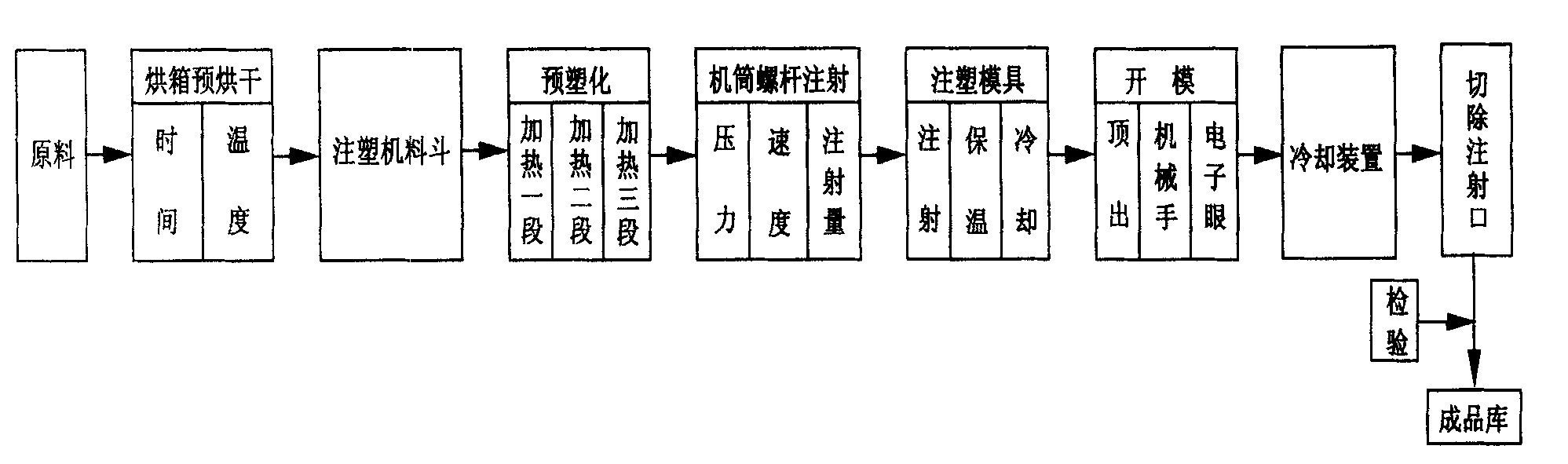

[0025] The one-time injection molding process of chlorinated polyvinyl chloride DN400 straight-through pipe fittings includes the following process:

[0026] 1. PVC-C (chlorinated polyvinyl chloride) raw material

[0027] 2. Drying box, the drying time of raw materials is 4 hours, and the temperature is 80-90°C

[0028] 3. Injection molding

[0029] 4. Pressure holding

[0030] 5. Cooling

[0031] 6. Mold opening

[0032] 7. Inspection

[0033] 8. Storage

[0034] The process parameters involved in the method are as follows:

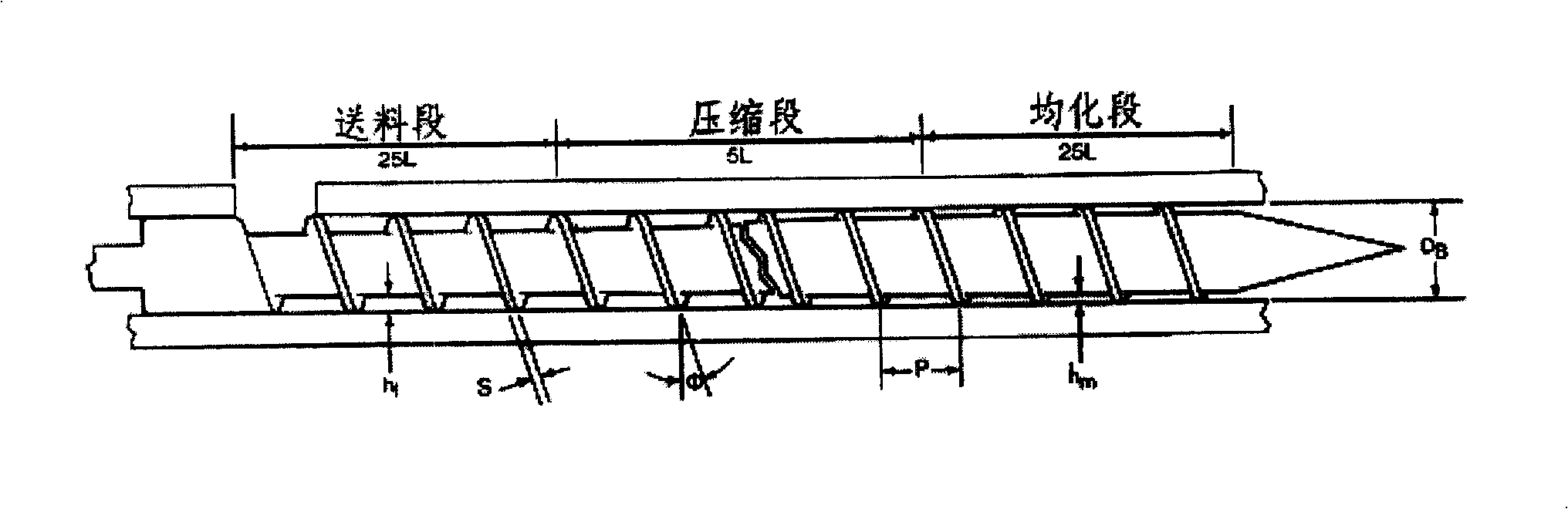

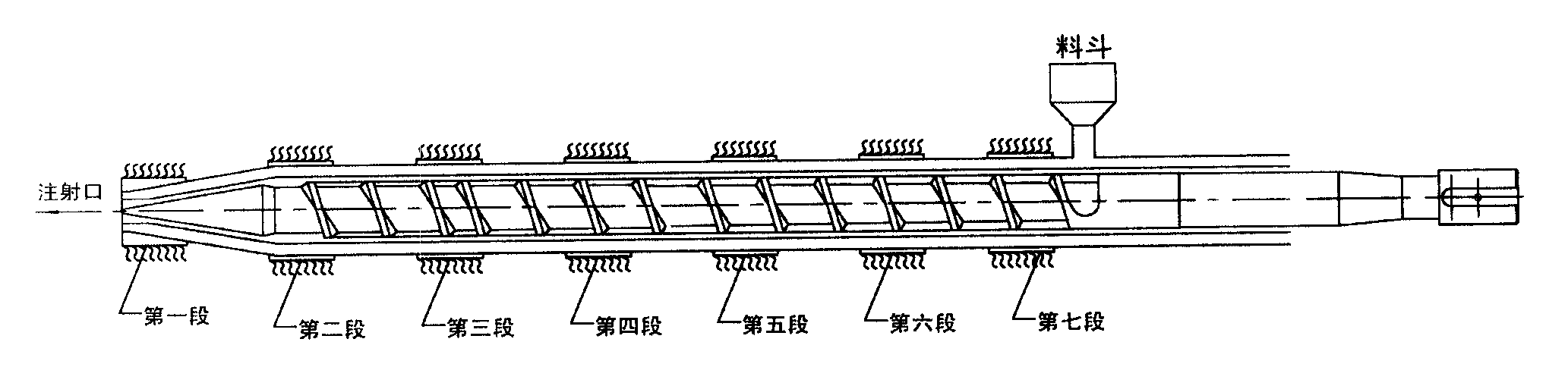

[0035] When selecting the temperature of the barrel, it should be ensured that the plastic is well plasticized, and the material can be successfully injected without causing the material to decompose. During the injection molding process, the heating part of the barrel of the injection molding machine is divided into seven sections, and the positions are evenly arranged. Each section is heated by The ring is heated separately, and the selected cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com