Producing technique for forging and rolling manganese metal

A technology for metal manganese and metal manganese pellets is applied in the field of new production technology for producing metal manganese by forging and rolling, and can solve the problems of irregular shape, limitation of metal manganese blocks, and many impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Use 5 tons of electrolytic manganese metal (DJM997), (quality index: Mn: 99.71%, C: 0.032%, S: 0.029%, P: 0.0064%, Si: 0.05%), it is broken into 60 mesh metal manganese powders, The material is then put into the silo.

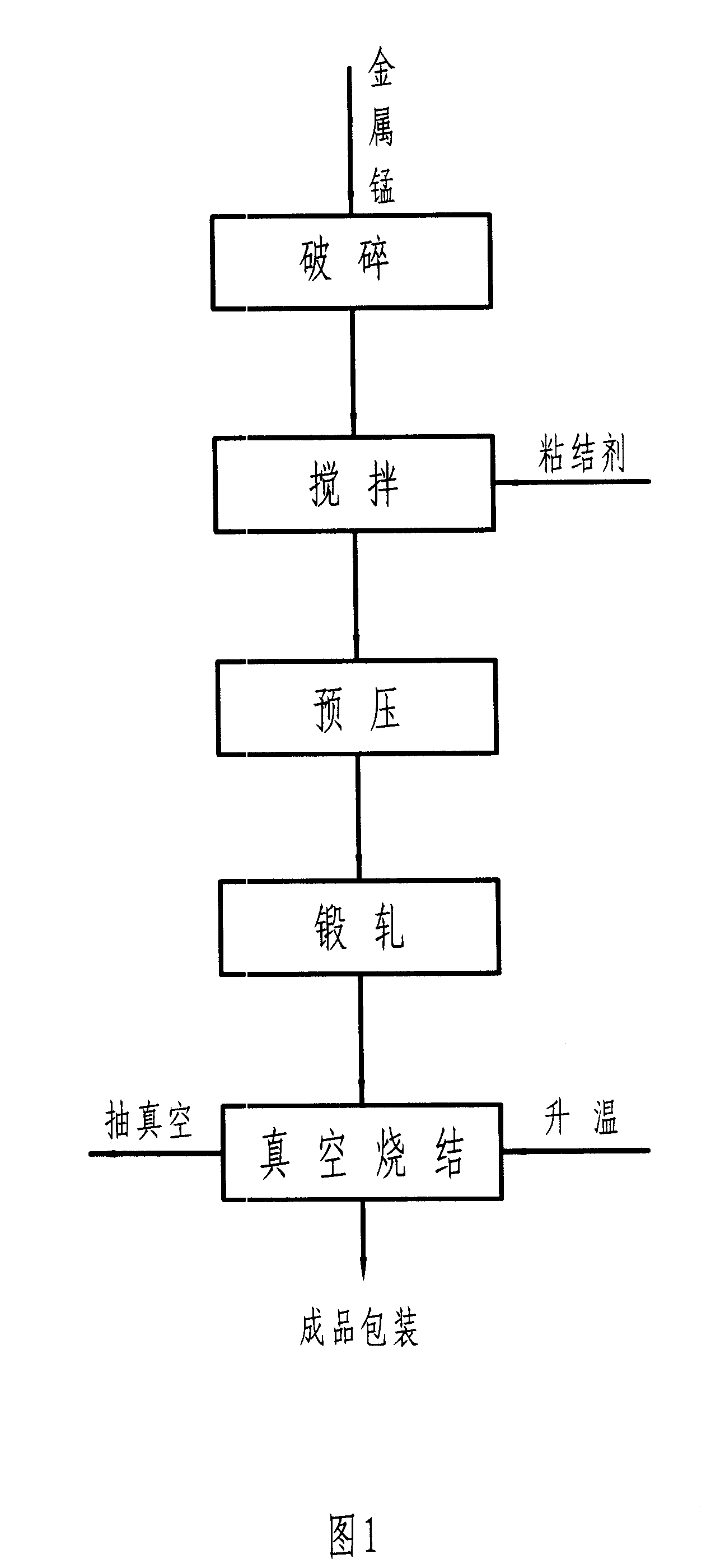

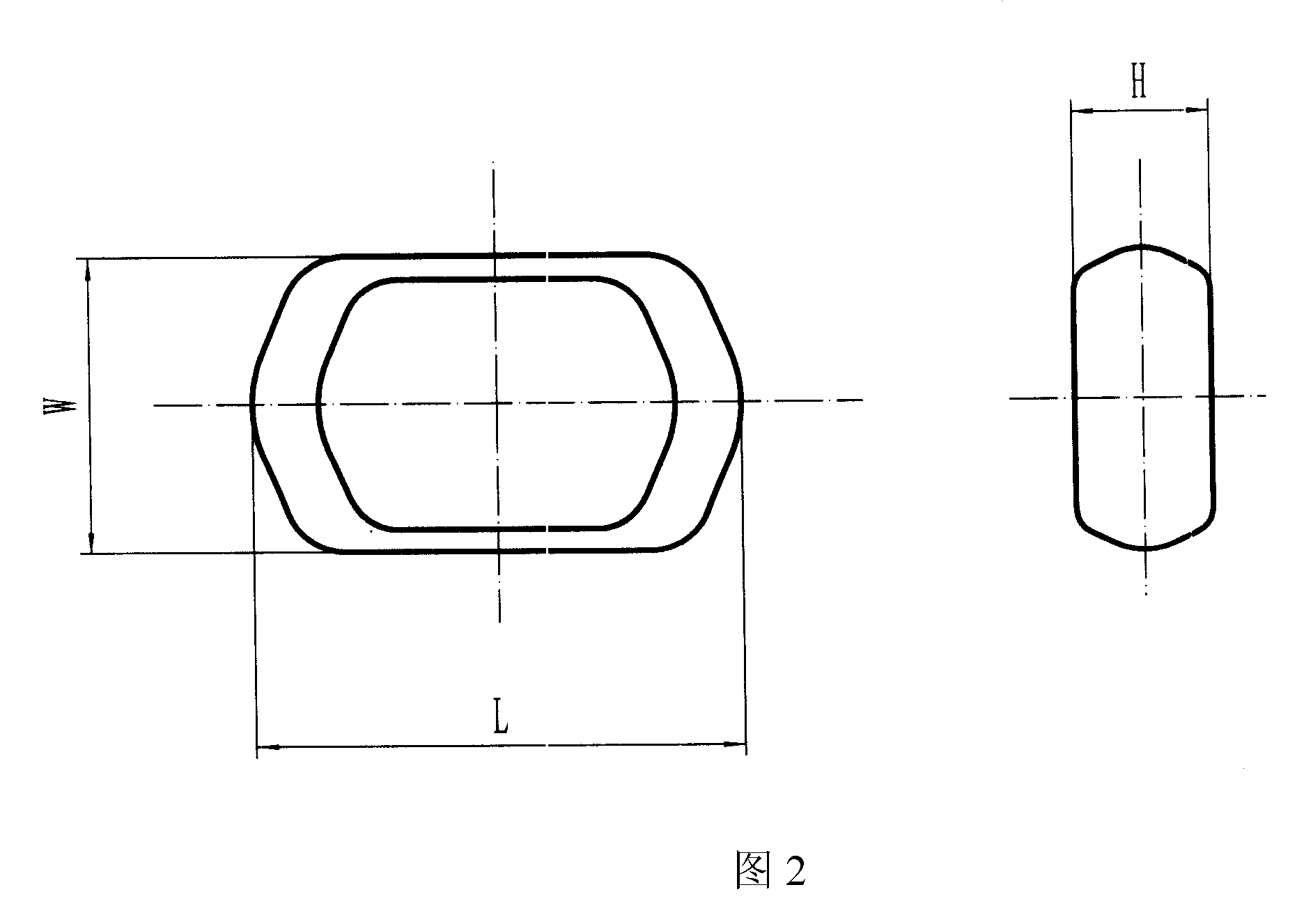

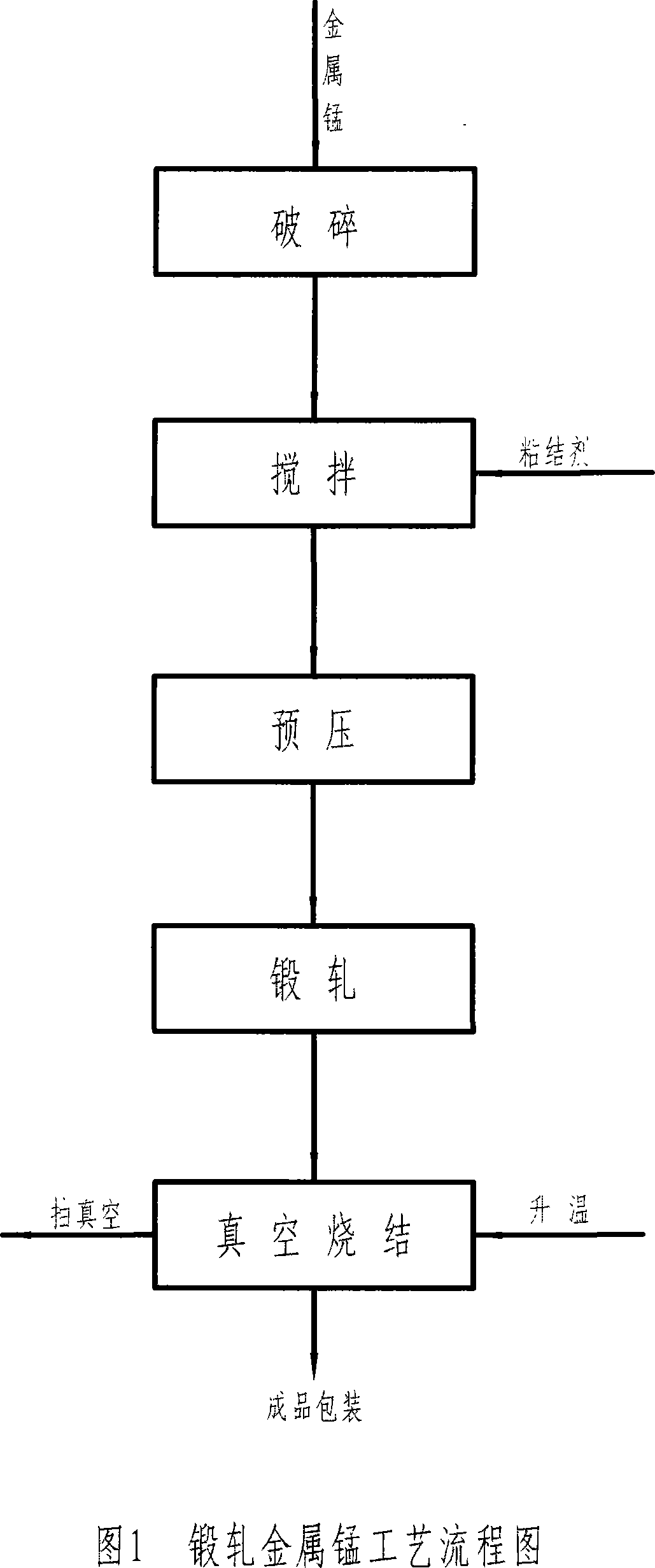

[0017] Put the metal manganese powder placed in the material bag into the airtight mixing equipment through the automatic metering and conveying device, input 1.25 tons for the first time, add binder----20 kg of water glass and 2.5 kg of curing agent, stir and mix After uniformity, the metal manganese powder is conveyed evenly and continuously to the pair-roll forging and rolling equipment through the belt conveying equipment. The pressing die of this forging equipment is ellipsoidal, and the size (L*W*H, see attached drawing 2) is 48mm*38mm*25mm. The pellets are put into a track car, and one car just holds 1.25 tons of materials. Repeat above-mentioned stirring, forging and rolling process, all remaining materials are forged and rolled and placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com