Dynamic light pressing control method

A control method and light pressing technology, applied in metal rolling and other directions, can solve the problem that the pressing area cannot be adjusted in place at one time, and achieve the effect of reducing the number of adjustments and reducing the negative impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

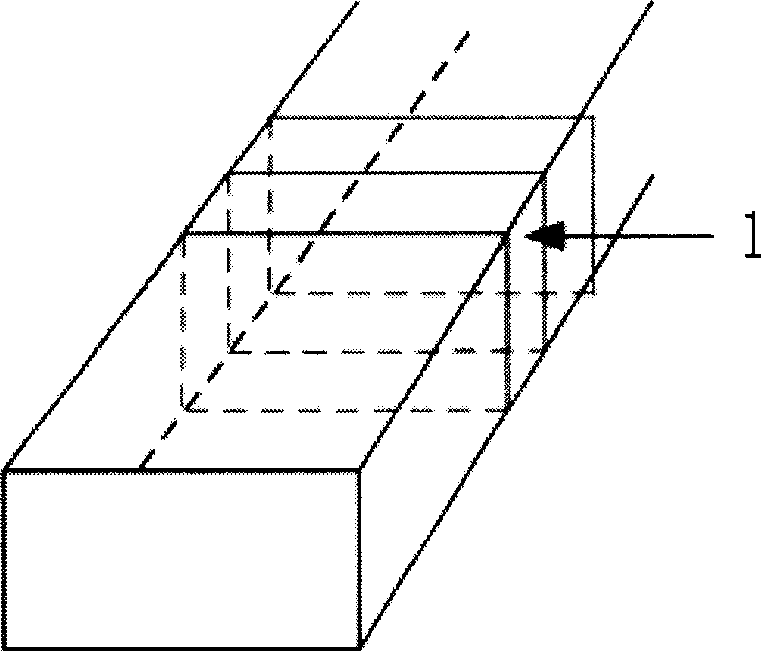

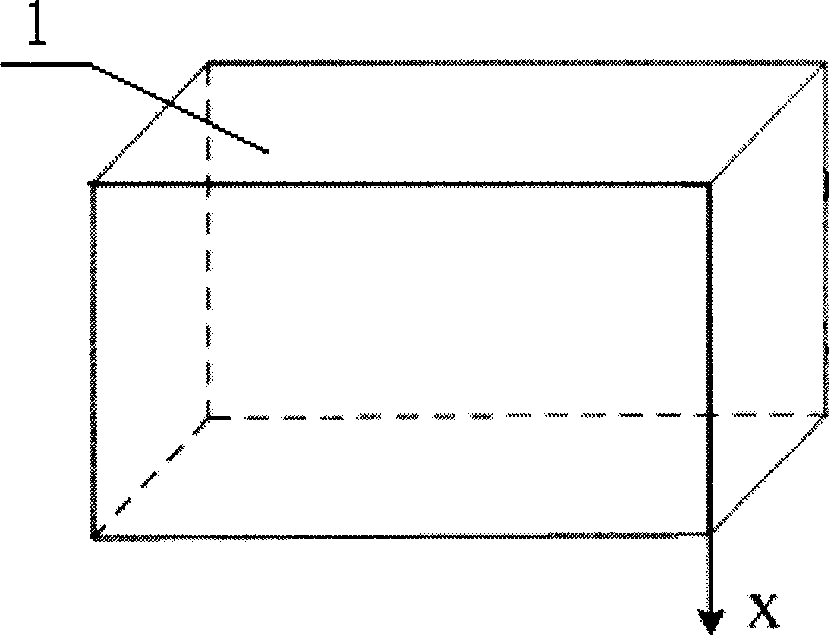

[0054]In order to set forth the content of the present invention more clearly, further description is made below with reference to the accompanying drawings and specific embodiments:

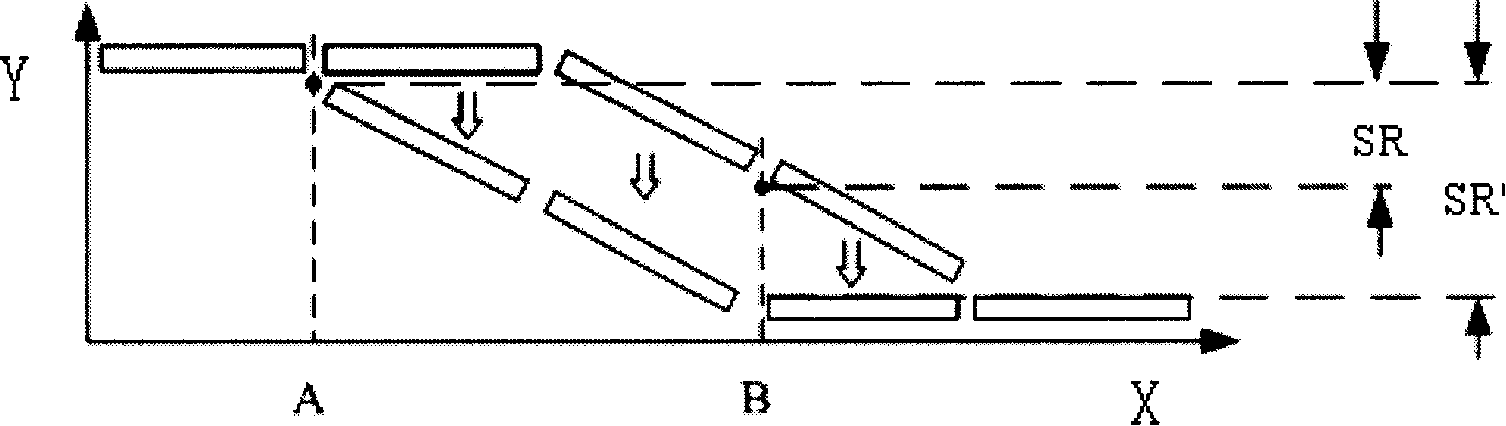

[0055] see Figure 7 , the dynamic soft reduction control method provided by the present invention adopts the following technical scheme every fixed time period (the time period can be determined according to specific equipment and site conditions, and the reference range can be selected as 2s ~ 2min). Predict the core position, and issue a new reduction command, a) First, according to the heat conduction equation, dynamically calculate the temperature distribution curve of the continuous casting slab at the current moment, and initially determine the current desired reduction state φ 1 (Assume that the actual pressing state of the current segment φ 0 );

[0056] b) If the current desired depression state φ calculated by the current control cycle 1 , and the current actual depression state φ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com