Valve moving device for internal combustion engine

A transmission device and internal combustion engine technology, applied in the direction of valve drive devices, internal combustion piston engines, valve devices, etc., can solve the problems of limited degrees of freedom, difficulty in stopping, etc., and achieve the effect of improving the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 3

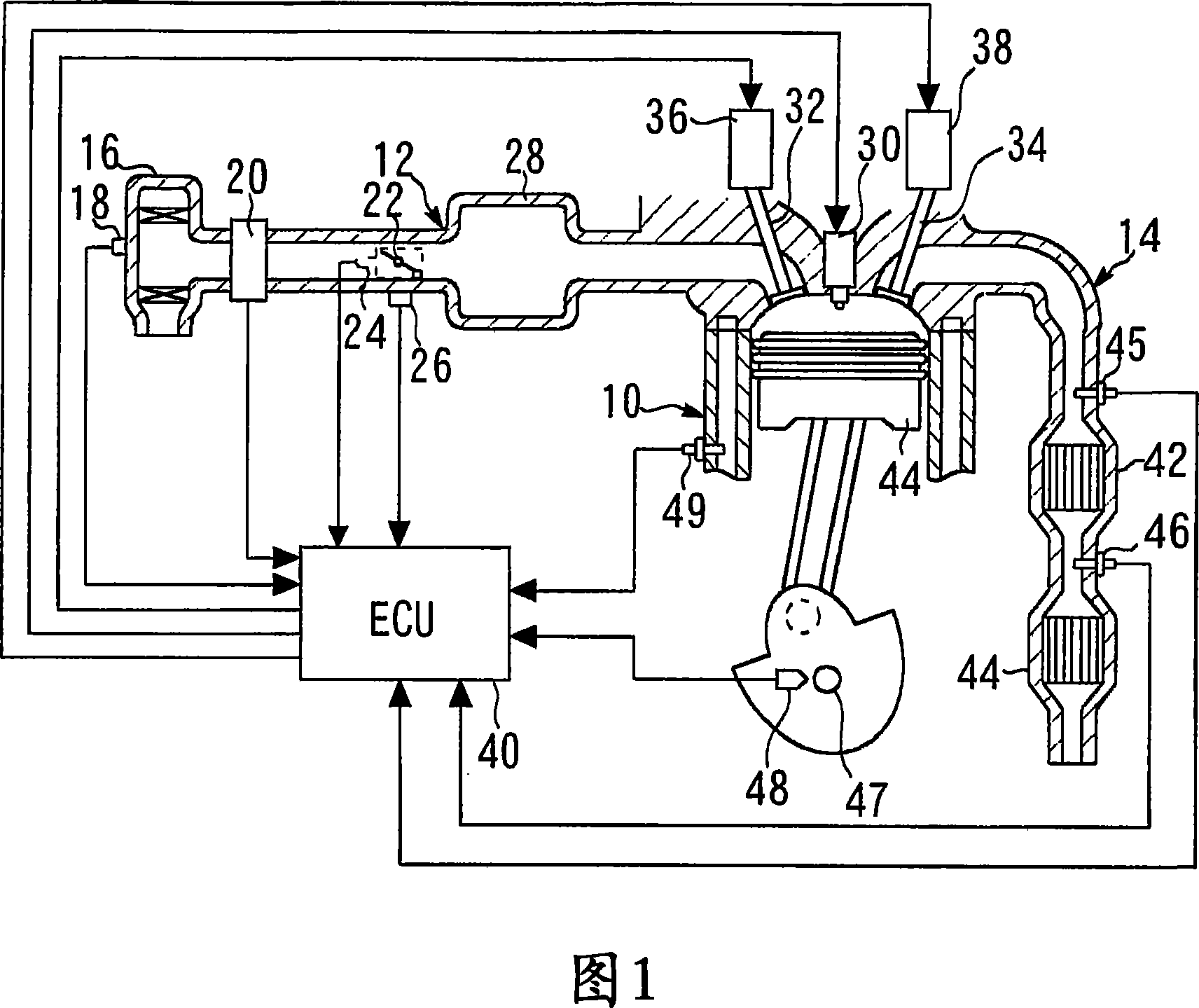

[0199] Next, Embodiment 3 of the present invention will be described. In Embodiment 3, the oxygen storage amounts of the catalysts 42 and 44 are reasonably controlled during the fuel-cut operation according to the driving of the intake valve 32 and the exhaust valve 34 .

[0200] In the system shown in FIG. 1 , the amount of oxygen stored in the catalysts 42 , 44 varies depending on the operating state of the internal combustion engine 10 . For example, when the air-fuel ratio is controlled to be lean, the oxygen storage amount of the catalysts 42 and 44 increases because the amount of oxygen in the exhaust gas increases. On the other hand, when the control to make the air-fuel ratio rich is performed, reducing components in the exhaust gas increase, and since oxygen is released from the downstream side catalysts 42 and 44, the oxygen storage amount decreases.

[0201] In particular, when the fuel increase control such as power increase is performed, the exhaust air-fuel rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com