Device and method for processing filter material for cigarette filters or similar

A filter material and pre-processing technology, applied in the direction of e-liquid filter elements, applications, tobacco, etc., can solve the problems of uncertain length, uncertain filter material strip broken, etc., to achieve the effect of ensuring leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

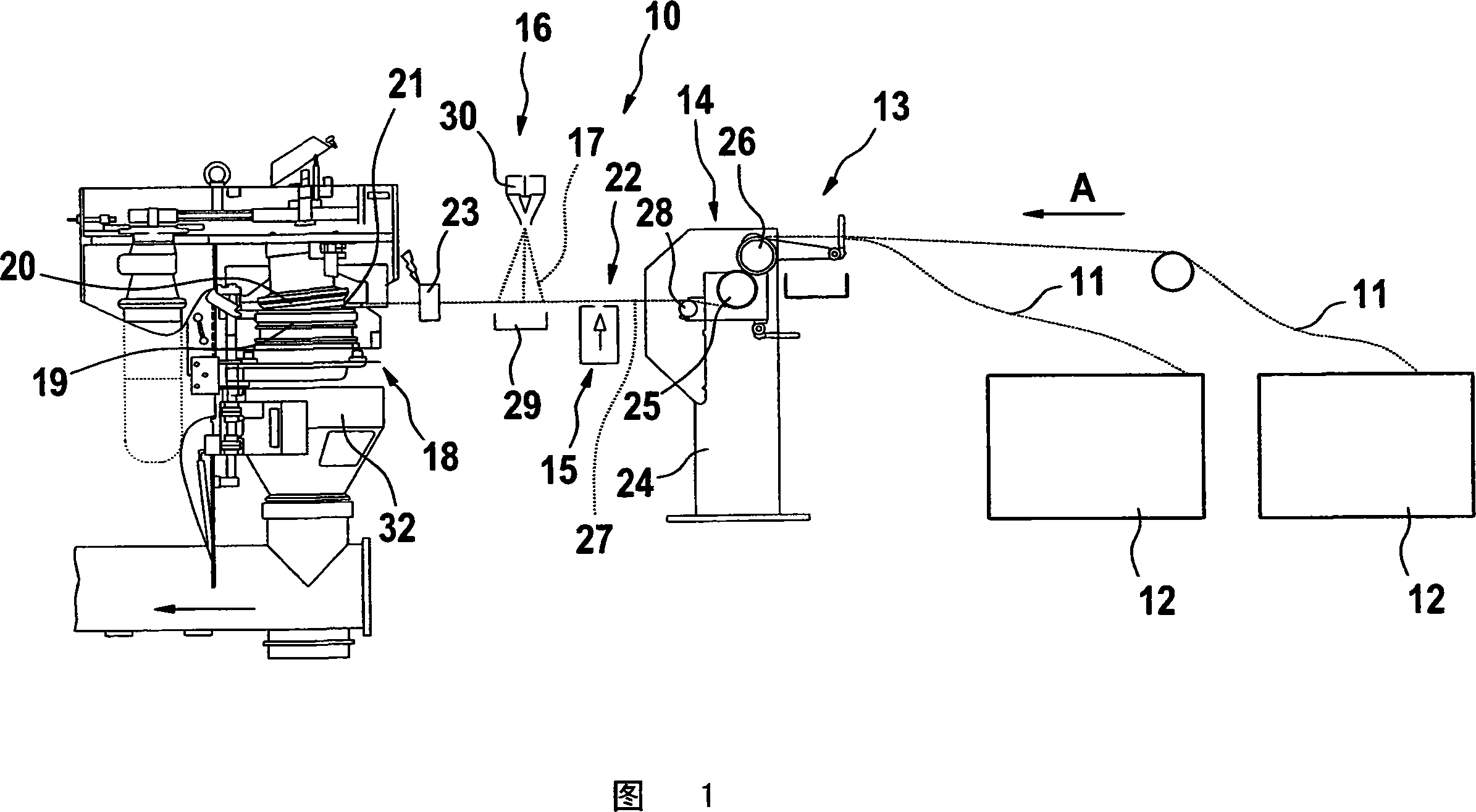

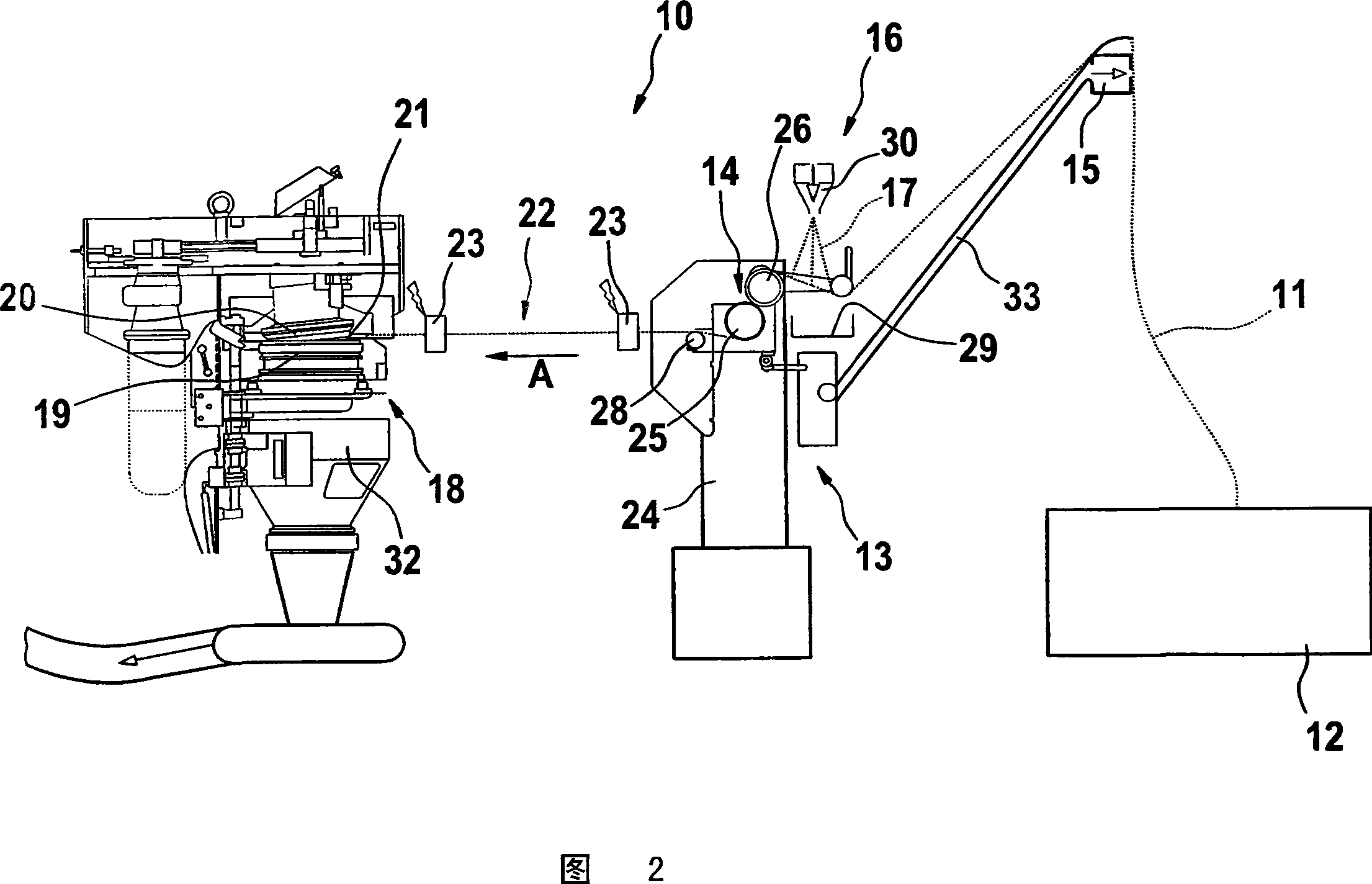

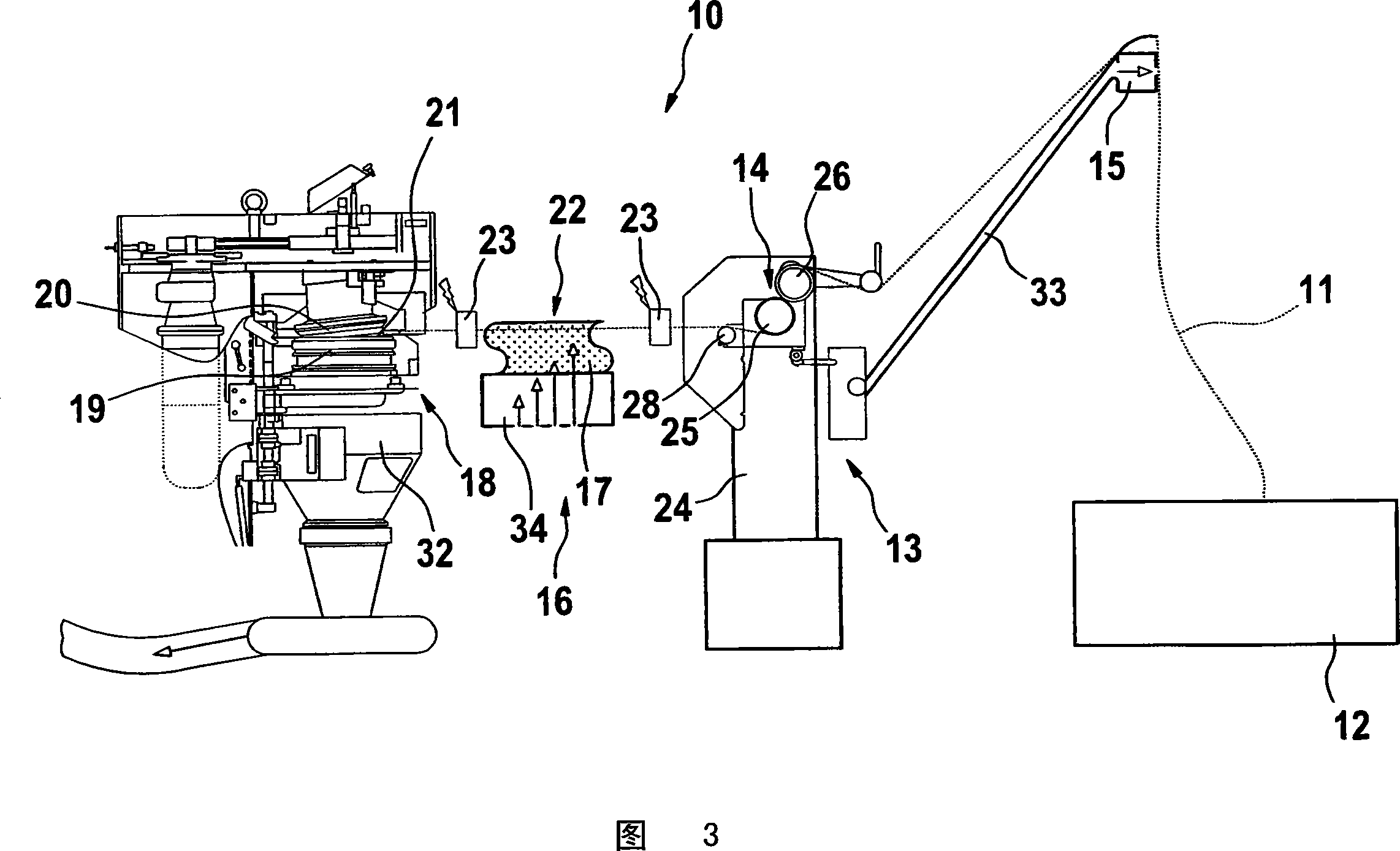

[0017] The equipment shown is used to pre-process filter material consisting of continuous fibers and / or final fibers used to make cigarette filters or the like.

[0018] The equipment 10 for pre-processing filter material (the material as a continuous strip of filter material 11 is preferably used in the form of a bundle 12) includes: a pull-out device 13 (the pull-out device includes a device for use at a speed V A A pair of rollers 14 for pulling out the filter material strip 11 from the material bundle 12); at least one nozzle 15 for spreading the filter material strip or each filter material strip 11; for applying water as a softener 17 to the filter material An application device 16 on the or each filter material strip 11; and a device 18 for breaking the filter material or each filter material strip 11 into individual material strips.

[0019] The applying device 16 is provided and formed for applying water as a softening agent 17 to the filter material strip or each filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com