W flame boiler primary air waste-steam replacement method and apparatus for

A secondary air and boiler technology, which is applied in combustion methods, non-flammable liquid/gas transportation, lighting and heating equipment, etc., can solve the problems of reduced main air flow rate, insufficient air jet stroke, and reduced airflow rigidity, so as to strengthen supplementary The effect of mixing with, reducing the carbon content of fly ash and improving the degree of burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

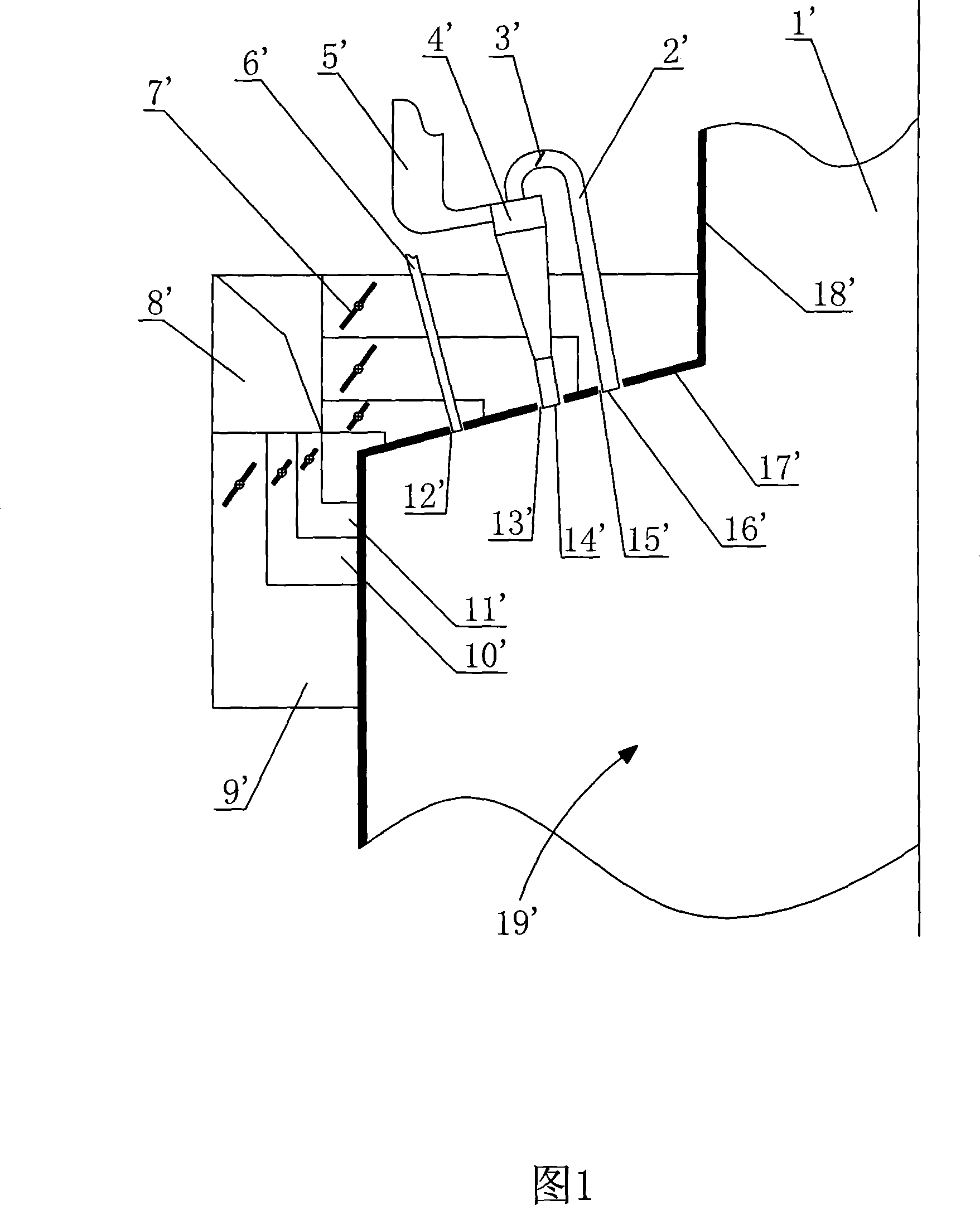

[0035] See Figures 2 and 3,

[0036] A method for replacing the primary air exhaust air of a W flame boiler according to the present invention: disconnect the primary air exhaust air pipe 31 of the cyclone separation type pulverized coal thick-lean burner 3 on the front and rear furnace arches 10 of the existing W flame boiler, and cancel the access to the combustion chamber. The exhaust air duct of the room; using the original primary air exhaust nozzle 32 and the position, 5% to 30% of the total amount of secondary air is transferred from this position at an angle of 0° to 60° to the vertical direction and The speed of 10-50m / s is injected downward into the combustion chamber.

[0037]The present invention is a W-flame boiler primary air depleted gas replacement device, which includes a combustion chamber 1 at the lower part of the boiler body, a burnout chamber 2 at the upper part of the boiler body, and a cyclone separation type pulverized coal thick-lean burner 3. The dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com