Dry helical lobe compressor host rotor spindle rotor spindle sealing structure

A dry-screw compressor and sealing structure technology, applied in machine/engine, sealing device of piston pump, mechanical equipment, etc., can solve the problems of easy wear of graphite sealing ring, leakage of compressor gas, reduction of air volume of unit, etc. The effect of low production cost, reduction of journal length, and reliable operation of the main engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

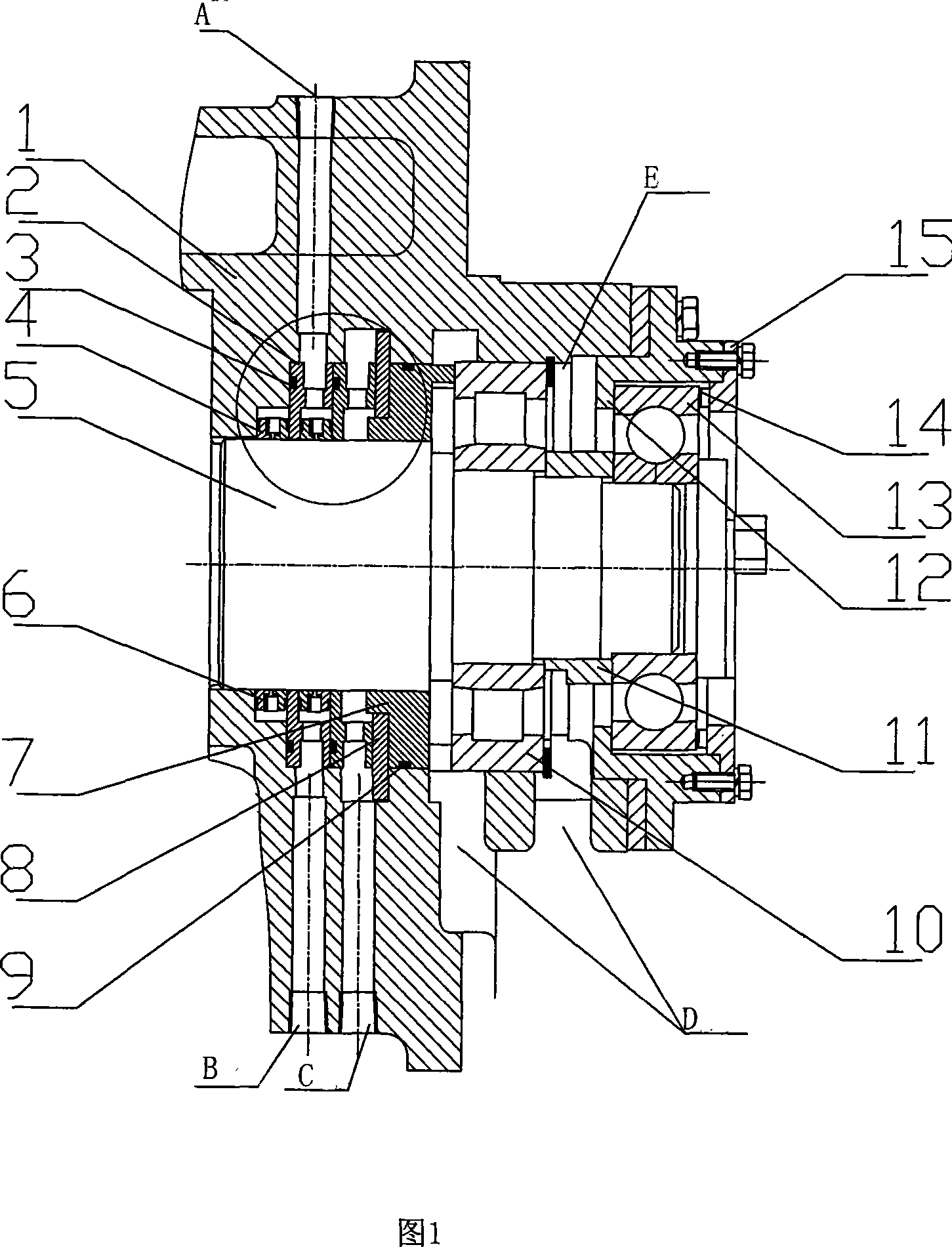

[0014] The seal of a single shaft shown in the figure includes: 1. Housing; 2. Spacer ring (2 pieces); 3. O-ring (2 pieces); 4. Stainless steel sealing ring (4 pieces); 5. Rotor; 6. Stainless steel wave Spring (2 sets); 7. Oil resistance ring (1 piece); 8. Press plate (1 piece); 9. O-ring (1 piece), etc.

[0015] On the casing 1, there are A hole, B hole-air vent hole, open to the atmosphere; D hole-oil return hole to return to the oil tank; C hole-oil drain hole, open to the atmosphere; H point-air seal; G point-resistance Cut off oil and gas communication; E - oil inlet; F - rectangular thread, effectively sealing oil.

[0016] In the present invention, the rotor shaft 5 is installed in the casing 1, the air is sealed by the stainless steel sealing ring 4, and the oil is sealed by the oil blocking ring 7.

[0017] Air seal: The gas side seal of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com