Novel rubber magnet and method for making same

A rubber magnet and system technology, applied in the direction of organic material/organic magnetic material magnetism, etc., can solve the problems such as the inability to obtain the shape of the rubber magnet, the large molding pressure, the easy fracture and deformation of the product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

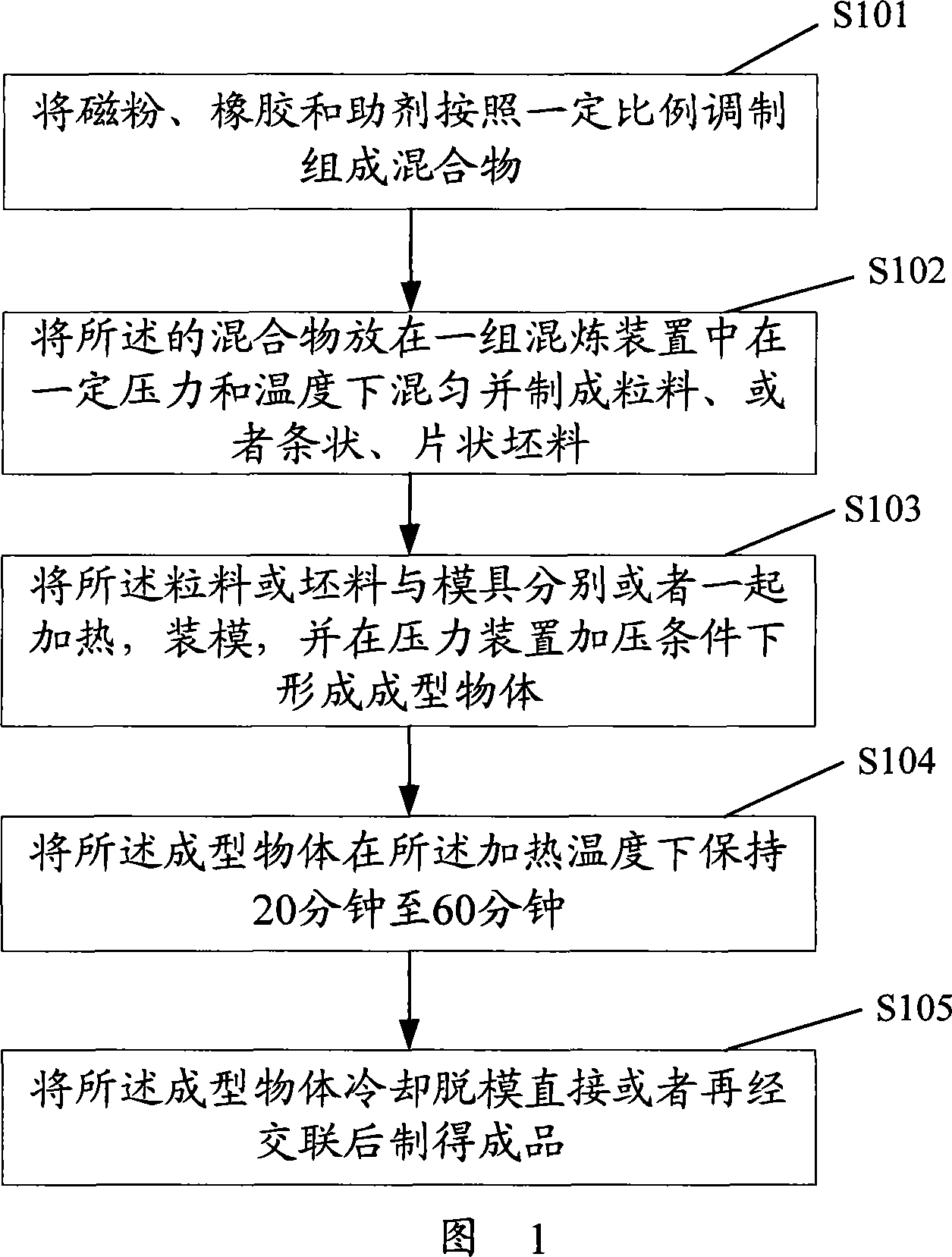

Method used

Image

Examples

Embodiment 1

[0054] The proportion (mass ratio) of the magnet formula is 95% of quick-quenched NdFeB magnetic powder (brand: XQP16-10), 3% of nitrile rubber, 0.1% of coupling agent (such as KH-550), other additives such as lubricant, Plasticizers, vulcanizing agents, etc. accounted for 1.9%. The above raw materials are uniformly mixed in a mixing device such as a mixer, a high mixer, a screw mixer, an open mill, a calender or an internal mixer to obtain a billet. Fill the billet into a Φ50mm×Φ45×50mm mold and heat it to 150°C for 30 minutes, then shape it on a hydraulic press at a pressure of 5t / cm2, keep it warm at 150°C for 20 minutes, and demould it after cooling to obtain the final product. The detected magnet density is 5.7g / cm3, and the magnetic performance is 8.5MGO.

Embodiment 2

[0056] The proportion (mass ratio) of the magnet formula is 41% of quick-quenched NdFeB magnetic powder (brand: XQP16-10), 51% of strontium ferrite magnetic powder, 6% of nitrile rubber, 0.1% of coupling agent (such as KH-550), Other additives such as lubricants, plasticizers, vulcanizing agents, etc. accounted for 1.9%. The above raw materials are uniformly mixed in a mixing device such as a mixer, a high mixer, a screw mixer, an open mill, a calender or an internal mixer to obtain a billet. Fill the billet into a mold of Φ87mm×Φ81×2mm and heat it to 180°C for 20 minutes, then shape it on a vulcanizer under a pressure of 3t / cm2, and demould it after cooling to obtain the final product. The detected magnet density is 4.67g / cm3, and the magnetic property is 4.1MGO.

Embodiment 3

[0058] The proportion (mass ratio) of the magnet formula is HDDR anisotropic NdFeB magnetic powder (brand: 4013H) 95%, nitrile rubber 3%, coupling agent 0.1% (such as KH-550), other additives such as lubricants, Plasticizers, vulcanizing agents, etc. accounted for 1.9%. The above raw materials are uniformly mixed in a mixing device such as a mixer, a high mixer, a screw mixer, an open mill, a calender or an internal mixer to obtain pellets. Fill the pellets into a Φ20mm×3mm mold and heat it to 165°C for 20 minutes, then shape it on a hydraulic press with a pressure of 1t / cm2, and apply an axially oriented electromagnetic field of 2.8T at the same time, keep it at 150°C for 20 minutes, and after cooling Demoulding to obtain the final product. The detected magnet density is 5.7g / cm3, and the magnetic property is 13MGO.

[0059] Through the novel rubber magnet and its preparation method provided by the embodiments of the present invention, a novel rubber magnet is prepared, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com