Methanol ammonoxidation explosion-proof yield increasing method

A methanol ammonia and methanol technology, which is applied in the field of methanol ammonia oxidation explosion-proof production increase, can solve the problems of short premixing time, hidden safety hazards, and long premixing time, and achieve the effects of increased production capacity, strong explosion-proof measures, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

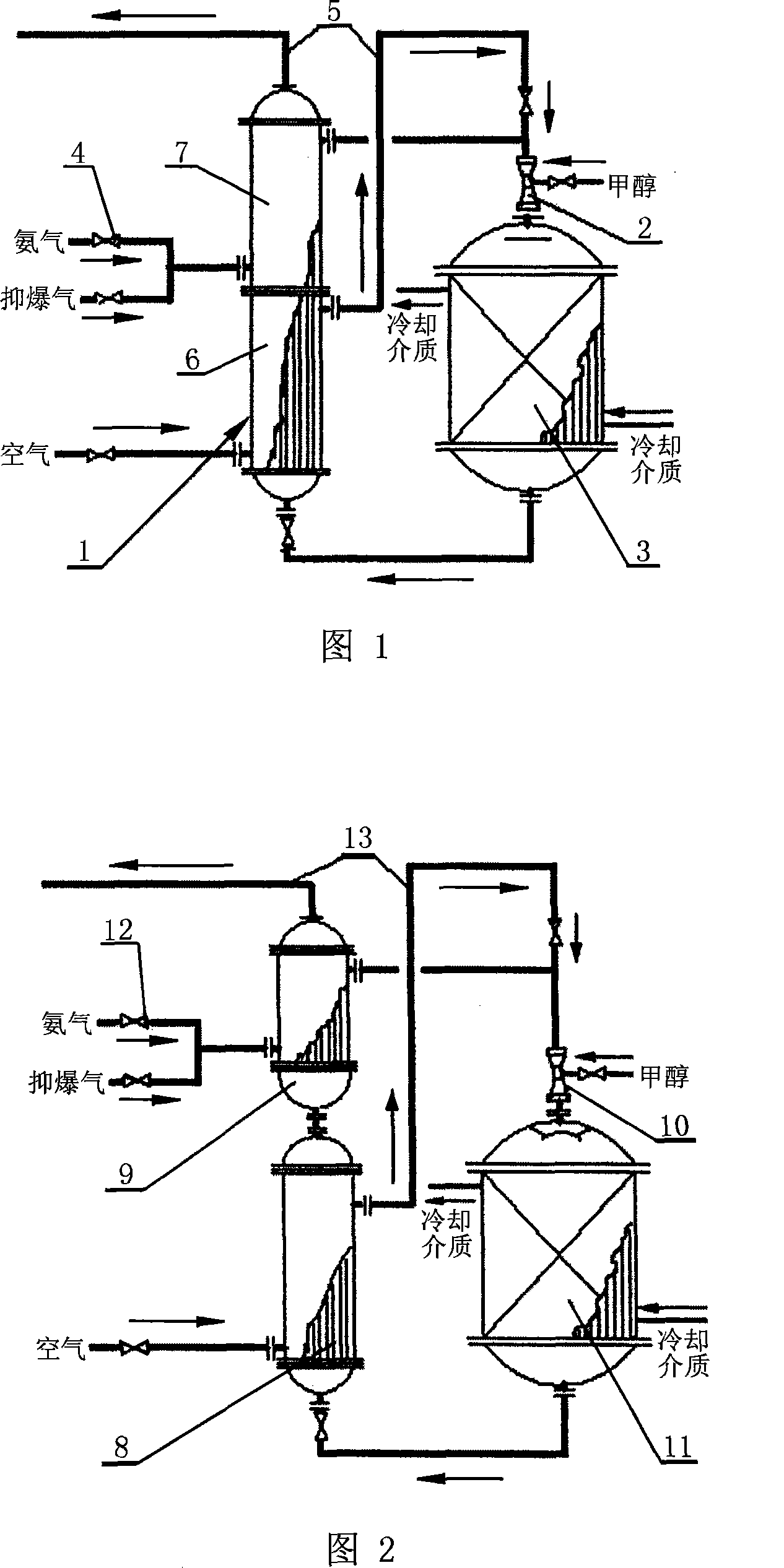

[0018] See attached figure 1 , an explosion-proof method for increasing production of methanol ammoxidation in the process of using iron / molybdenum oxide to catalyze methanol ammoxidation. It is used in new production systems that use methanol, ammonia and air as raw materials and use iron / molybdenum oxides to catalyze the ammoxidation of methanol.

[0019] Nitrogen is used as the explosion suppression gas in the methanol ammoxidation process; the heat exchanger adopts a two-stage shell and tube heat exchanger 1, so that the flammable gas methanol vapor and ammonia are heated separately from the air; the air, methanol and ammonia are heated The top of the fixed-bed catalytic reactor 3 is mixed, and the mixed gas is in a downward flow direction that is not conducive to explosion. The gas distribution process index of raw material mixed gas is: nitrogen 20-25%, methanol 7-8%, ammonia 7.7-8.8%, air 58.2-65.3%. The equipment and pipelines are designed according to ≥0.6Mpa, and ...

Embodiment 2

[0022] See attached figure 2, an explosion-proof method for increasing production of methanol ammoxidation in the process of using iron / molybdenum oxide to catalyze methanol ammoxidation. It is used in new production systems that use methanol, ammonia and air as raw materials and use iron / molybdenum oxides to catalyze the ammoxidation of methanol. Nitrogen is used as the explosion suppression gas in the methanol ammoxidation process; the heat exchanger uses two tube-and-tube heat exchangers to separate the flammable gas methanol vapor and ammonia from the air; the air, methanol and ammonia are fixed The top of the bed catalytic reactor 11 is mixed, and the mixed gas is in a downward flow direction which is not conducive to explosion. The gas distribution process index of raw material mixed gas is: nitrogen 20-25%, methanol 7-8%, ammonia 7.7-8.8%, air 58.2-65.3%. The equipment and pipelines are designed according to ≥0.6Mpa, and the piping is designed according to figure 2...

Embodiment 3

[0026] See attached figure 1 , an explosion-proof method for increasing production of methanol ammoxidation in the process of using iron / molybdenum oxide to catalyze methanol ammoxidation. It is used in new production systems that use methanol, ammonia and air as raw materials and use iron / molybdenum oxides to catalyze the ammoxidation of methanol.

[0027] Adding water vapor is used as explosion suppression gas in methanol ammoxidation process; the heat exchanger adopts two-stage tube heat exchanger 1 to separate the flammable gas methanol vapor and ammonia from air; the air, methanol and ammonia Mix at the top of the fixed-bed catalytic reactor 3, and make the mixed gas in a downward flow direction that is not conducive to explosion. The gas distribution process index of raw material mixed gas is: water vapor 16-21%, methanol 7-8%, ammonia 7.7-8.8%, air 62.2-69.3%. The equipment and pipelines are designed according to ≥0.6Mpa, and the piping is designed according to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com