Method of welding L type aluminum alloy section agitating friction welding

An aluminum alloy profile, friction stir welding technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as special shape, uneven thickness of profiles, etc., to enhance plastic flow and improve heat deficiency , to achieve the effect of high-quality welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

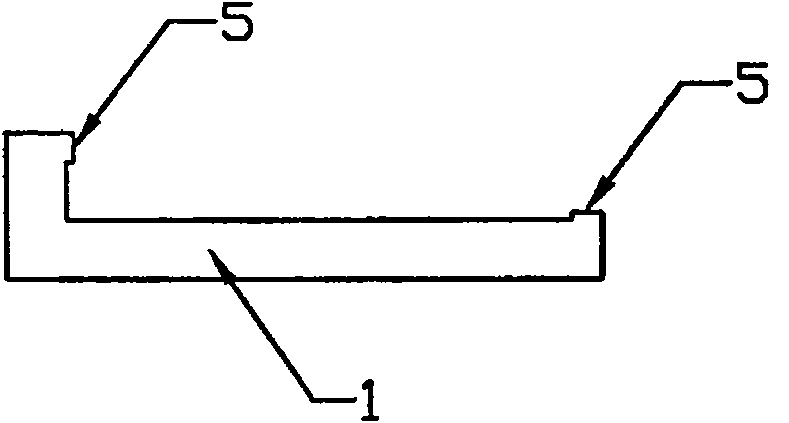

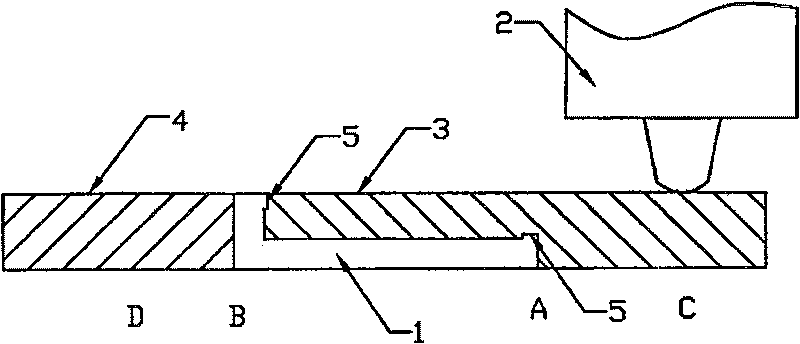

[0023] The schematic diagram of the reverse side welding work of the present invention is as figure 2 As shown, the short side of the L-shaped aluminum alloy profile 1 faces upwards, and the auxiliary block A3 is an aluminum alloy block whose shape matches the inner shape of the L-shaped aluminum alloy profile. Assembled above the inner side of the L-shaped aluminum alloy profile, on the outside of the short side of the L-shaped aluminum alloy profile 1, the auxiliary pad B4 is assembled, and the auxiliary pad A3 and two butt-connected L-shaped aluminum alloy profiles 1 ( figure 2 Only the cross-section of the first L-shaped profile 1 can be seen, and the cross-section of the second L-shaped profile 1 is covered by the cross-section of the first L-shaped profile 1 . ) and the auxiliary block B4 are laterally clamped on the welding workbench by the tooling to form a rectangular cross-sectional structure.

[0024] The length of the stirring head 2 installed on the friction st...

Embodiment 2

[0029] The working diagram of the front welding of the second embodiment of the present invention is as follows: image 3 As shown, the short side of the L-shaped aluminum alloy profile 1 is downward, the auxiliary pad A3 is assembled under the inner side of the L-shaped aluminum alloy profile 1, and the auxiliary pad B4 is assembled on the outside of the short side of the L-shaped aluminum alloy profile 1. The auxiliary block A3, two butted L-shaped aluminum alloy profiles 1 ( image 3 Only the cross-section of the first L-shaped aluminum alloy profile 1 can be seen, the cross-section of the second L-shaped aluminum alloy profile 1 is covered by the cross-section of the first L-shaped aluminum alloy profile 1) and the auxiliary block B4 , clamped horizontally on the welding workbench by the tooling to form a rectangular cross-sectional structure.

[0030] When welding the front side, the stirring head 2 starts to rotate from point A and inserts the auxiliary pad A3, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com