Embedded digitalization multifunctional inversion type flexible switch arc-welding power supply based on ARM

An arc welding power supply and embedded technology, which is applied in the field of ARM-based embedded digital multifunctional inverter soft-switching arc welding power supply, can solve the problems of no products, and achieve saving of manufacturing materials, high-quality welding quality, precise control and The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the drawings and embodiments, but the embodiments of the present invention are not limited thereto.

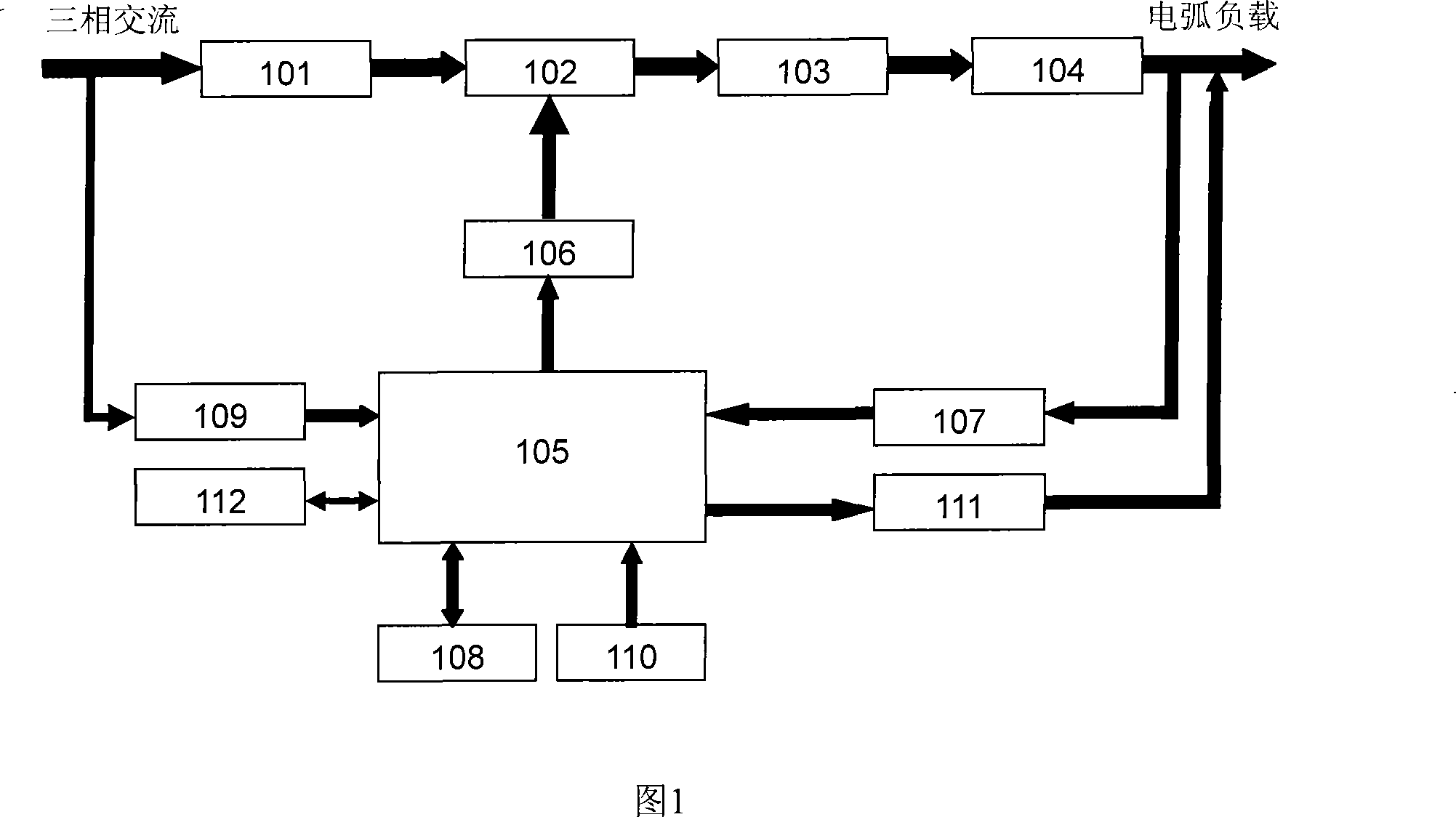

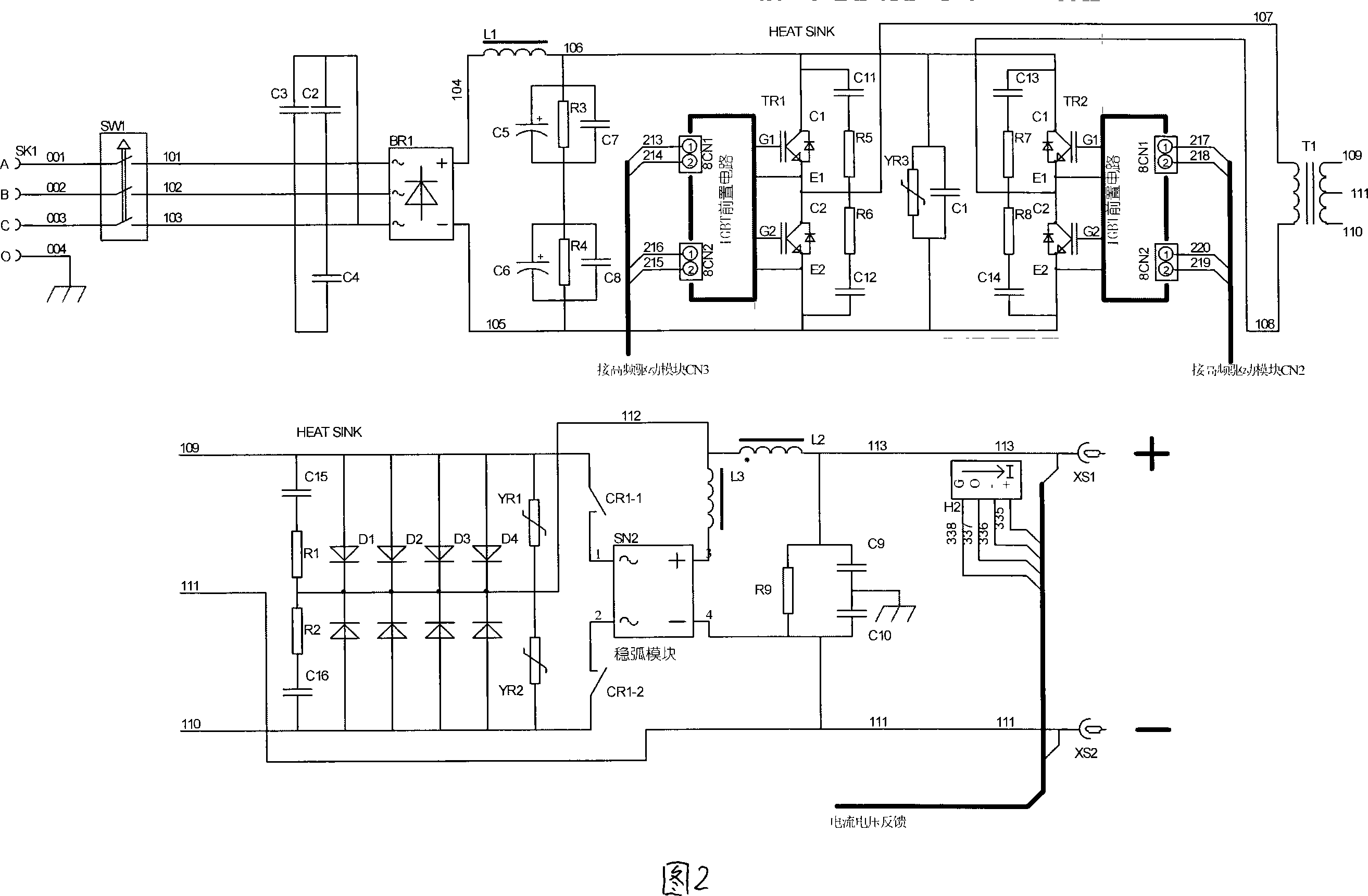

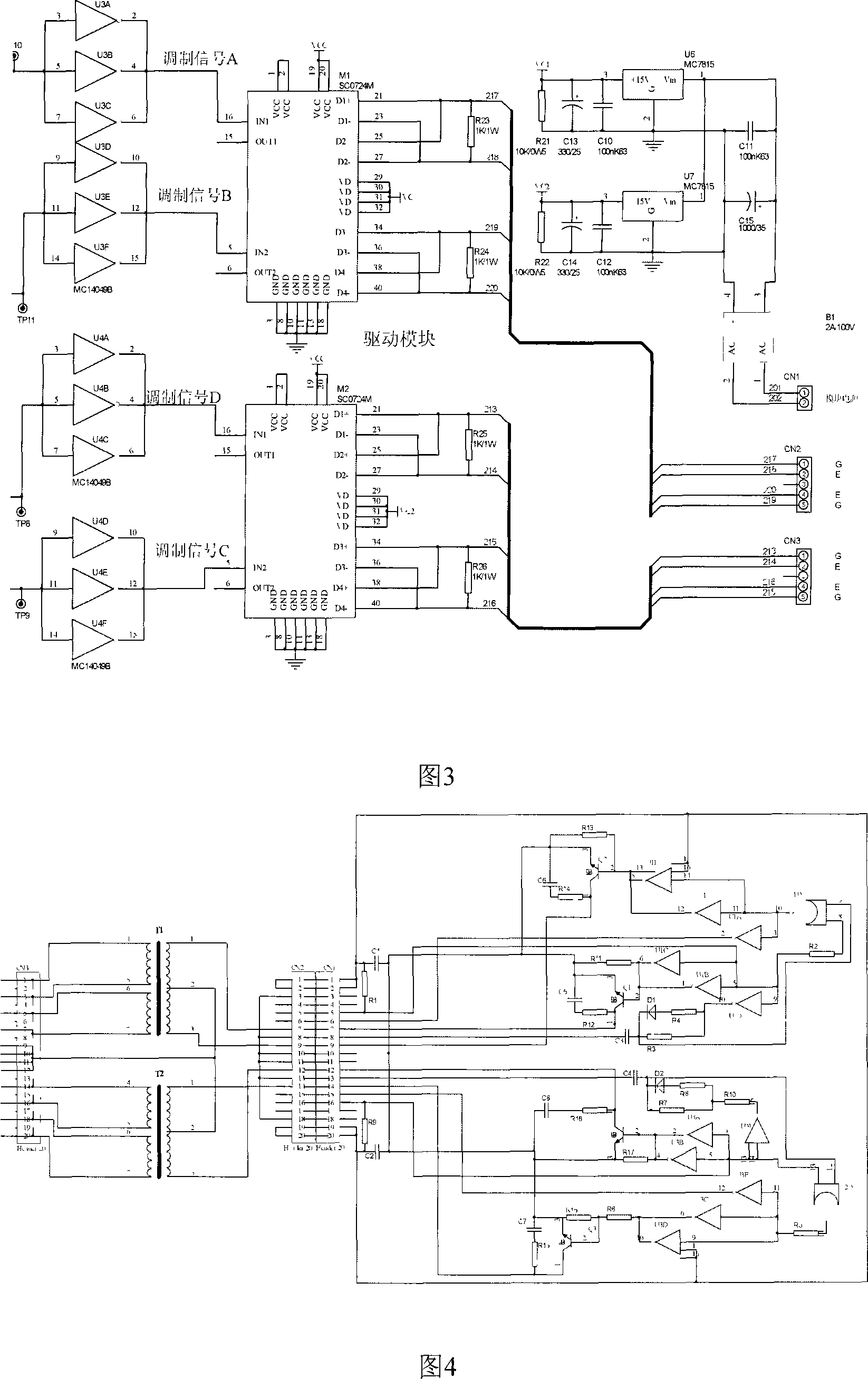

[0026]As shown in Fig. 1, the ARM-based embedded digital multifunctional inverter soft-switching arc welding power source of the present invention includes a main circuit, a control circuit and a high-frequency arc starting circuit connected to each other. The main circuit consists of a rectification and filtering module 101, a high-frequency inverter module 102, a power transformation module 103, and a rectification smoothing and arc stabilizing module 104, which are connected in sequence. Module 104 is connected to a load. The control circuit includes an overvoltage and undervoltage protection detection module 109, a current and voltage sampling detection and feedback module 107, an ARM microcontroller 105 and a high-frequency drive module 106 connected to each other, and the ARM microco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com