Self-washing type non-ferro metals debris reclaimer and its using method

A technology for non-ferrous metals and recovery devices, applied in solid separation, flotation, etc., can solve the problems of tailings re-selection recovery, comprehensive utilization, etc., and achieve high recovery rate and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

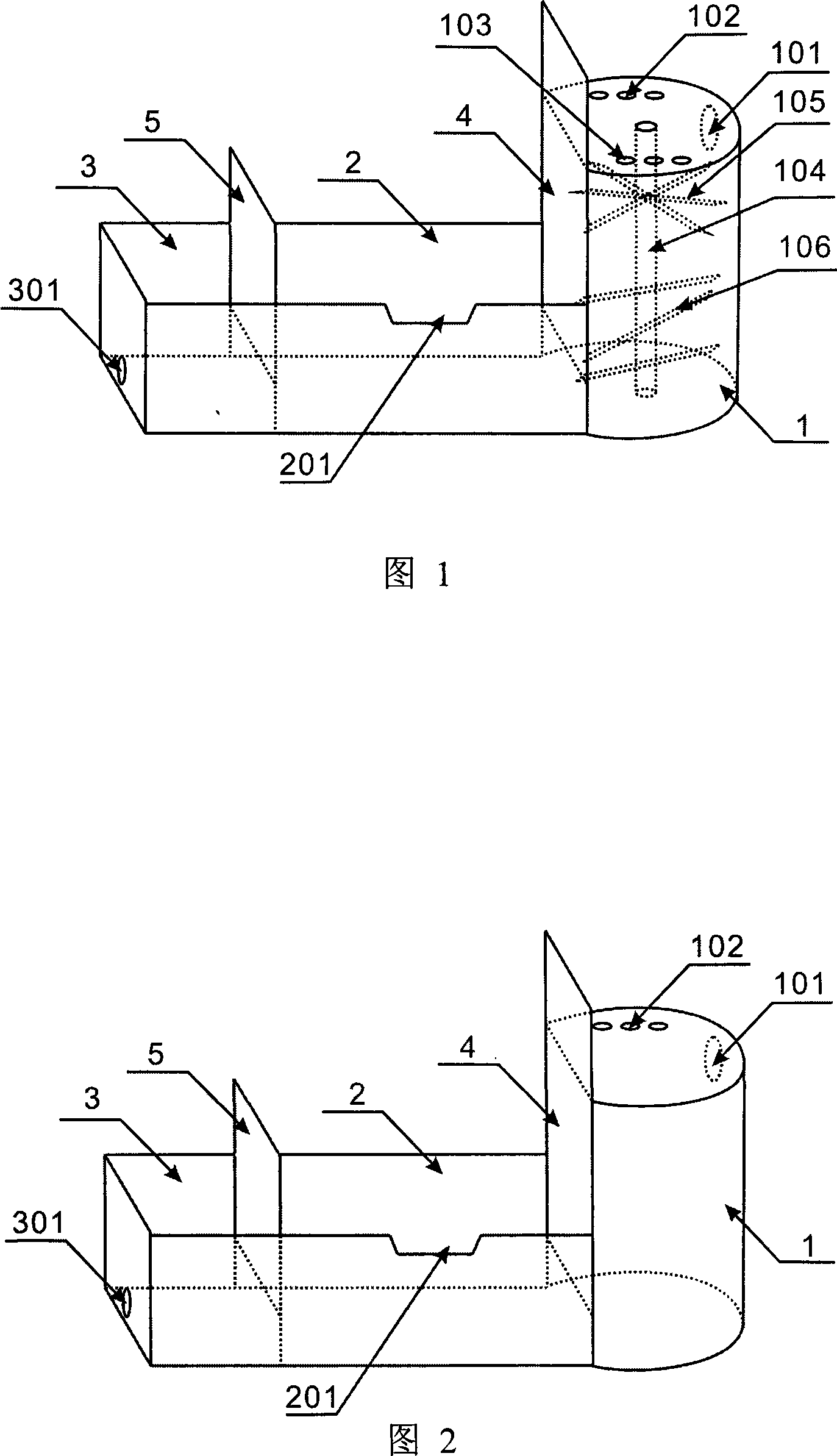

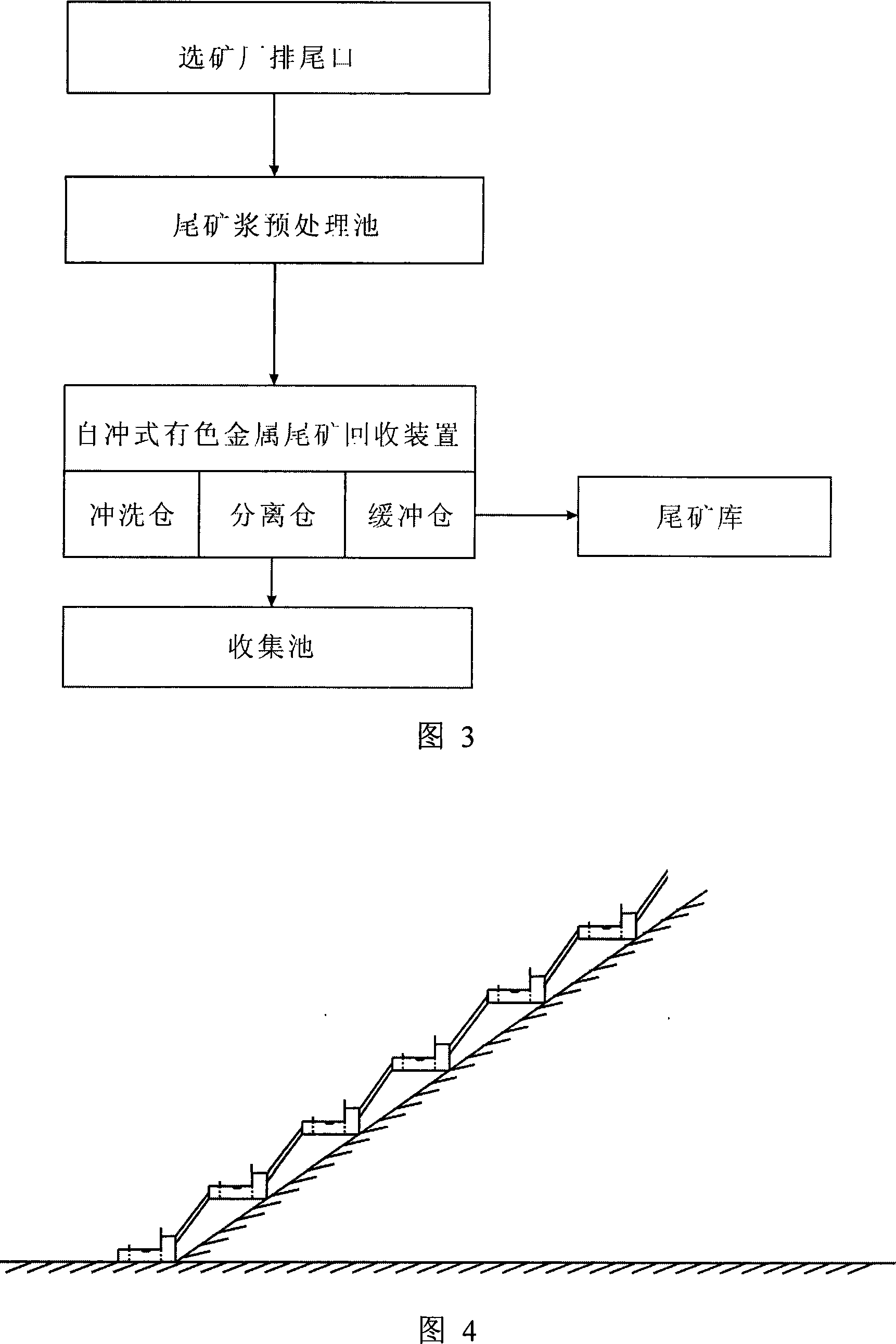

[0032] Figure 1 is a schematic structural diagram of Embodiment 1 of a self-flushing non-ferrous metal tailings recovery device. As shown in the figure, a self-flushing type non-ferrous metal tailings recovery device includes an impact bin 1, a separation bin 2 and a buffer bin 3; the impact bin 1, separation bin 2 and buffer bin 3 are sequentially connected into an integrated structure; The impact chamber 1 is provided with a water inlet 101 for the tailings slurry to flow into; an impact gate 4 is provided between the impact chamber 1 and the separation chamber 2, and an adjustment gate 5 is provided between the separation chamber 2 and the buffer chamber 3 A water outlet 301 is provided on the side panel of the buffer storehouse 3 opposite to the regulating ram 5 ; an overflow for the outflow of the mineralized foam is provided on the side panel of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com