Linear motor and machine tool having the same mounted thereon

一种线性电动机、动作的技术,应用在机床领域,能够解决结构变复杂、零部件数量增加等问题,达到简单结构、防止落下、结构紧凑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

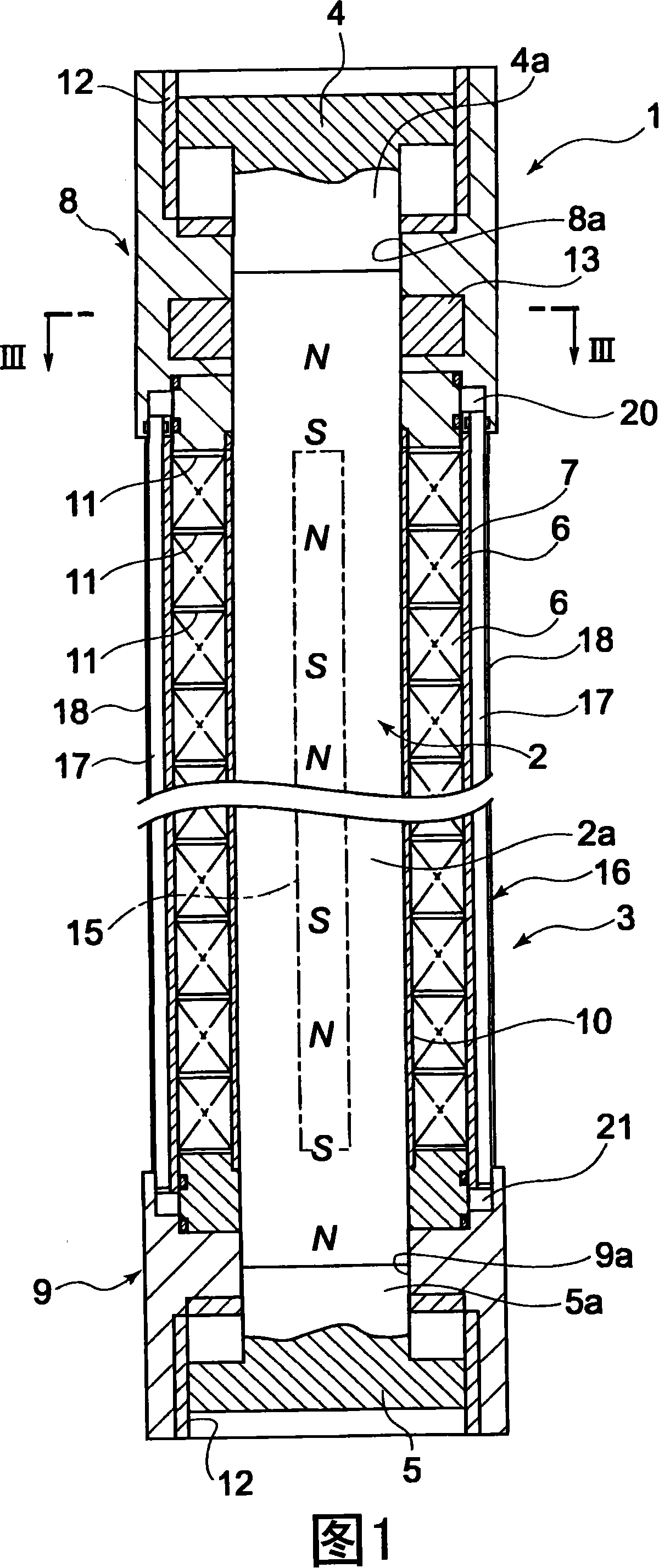

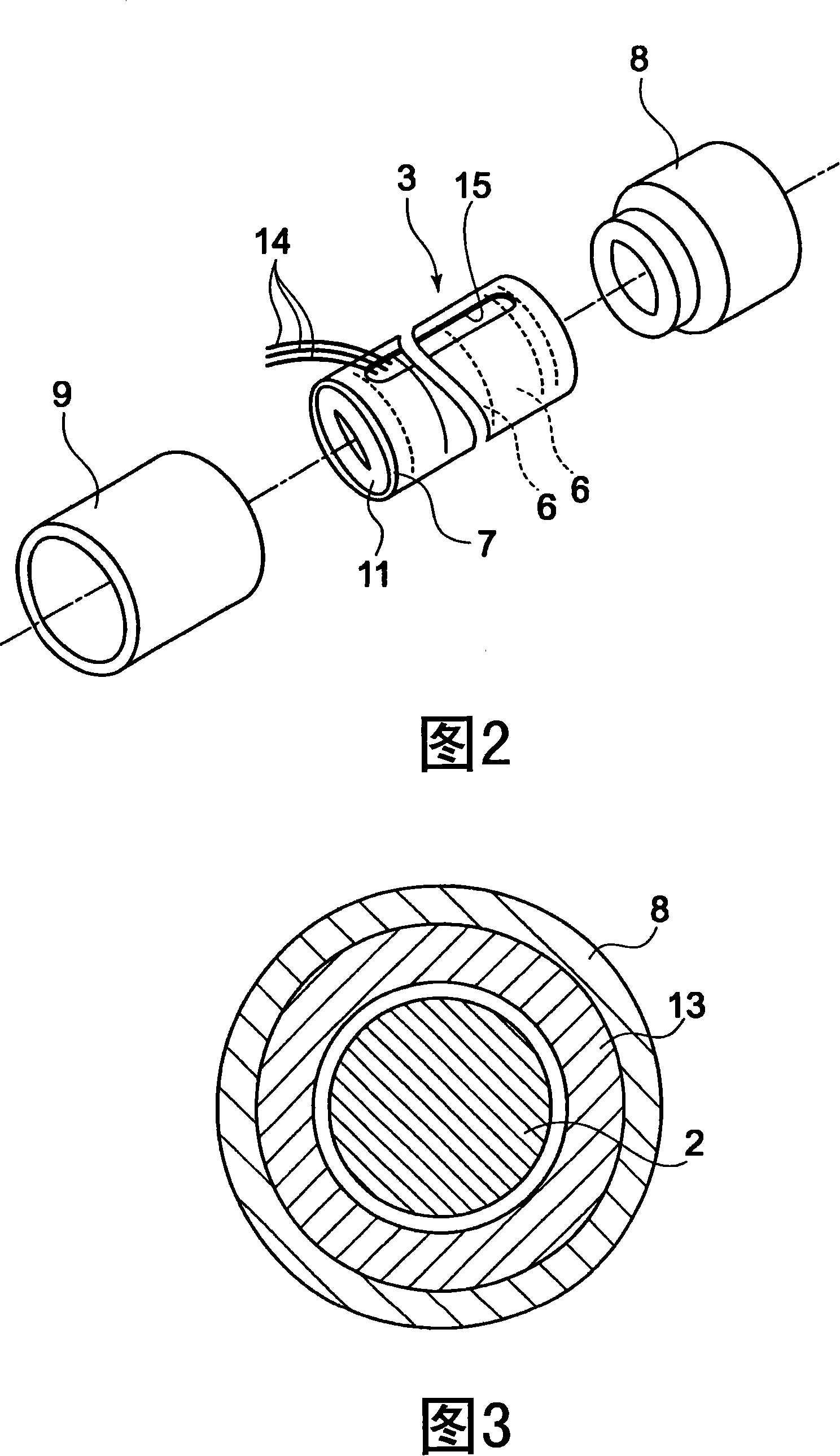

[0024] Next, a first embodiment of the present invention will be described with reference to FIGS. 1 to 3 . This linear motor 1 includes a magnet member 2 and a coil member 3. The magnet member 2 is composed of permanent magnets whose N poles and S poles are alternately arranged in a predetermined axial direction. The coil member 3 surrounds the magnet member 2. The magnet member 2 is allowed to move relatively freely in the axial direction inside. The coil member 3 is a stator, and the magnet member 2 is a moving body.

[0025] The magnet member 2 is a member in which sliders 4, 5 are attached to both ends of a magnet member main body 2a made of a round bar-shaped permanent magnet.

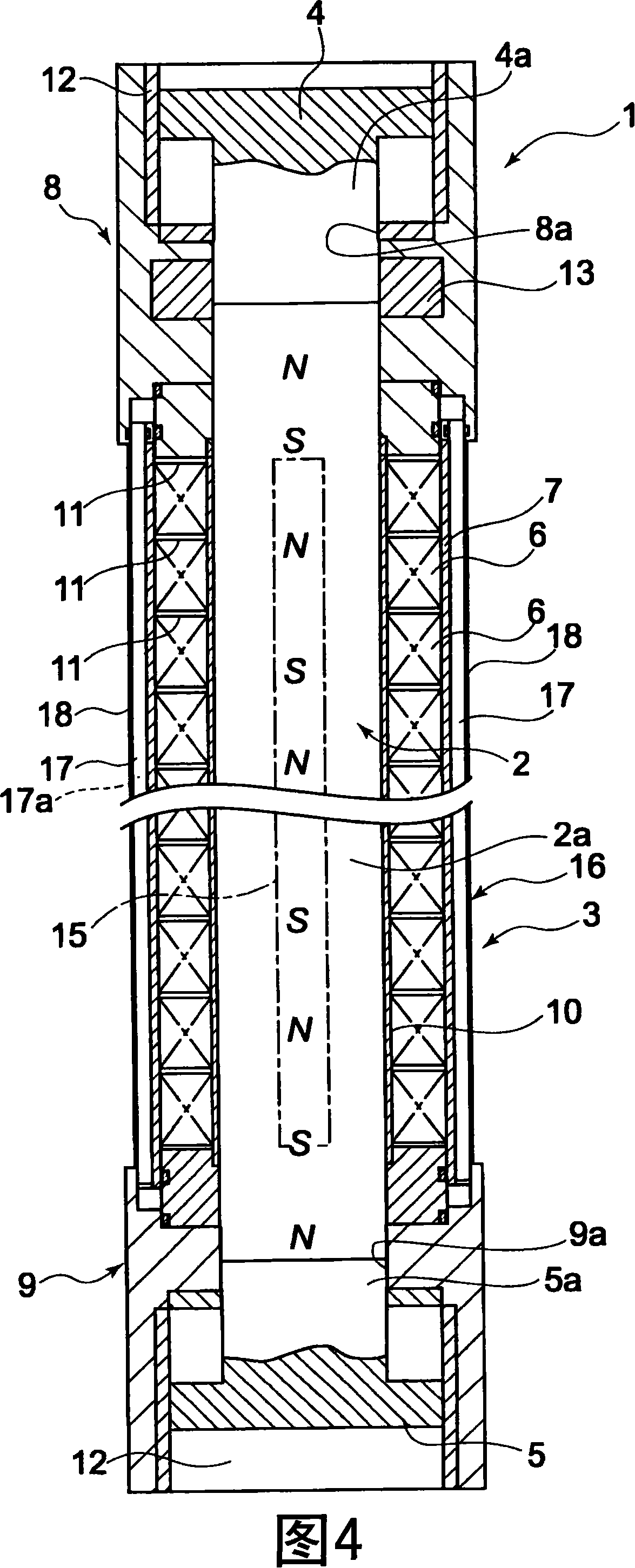

[0026] The coil member 3 has a structure in which a plurality of cylindrical coils 6 surrounding the magnet member 2 are arranged in an axial direction. The plurality of coils 6 described above are housed in a common cylindrical coil case 7 , and caps 8 and 9 are attached to both ends of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com