Connecting structure for trolley tine and tine holder

A technology of connection structure and tooth seat, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of impact, friction damage pin performance, no contact and fixation of bucket teeth, and reduced bearing capacity of bucket teeth, etc., to achieve structural Simple and reliable, prolong life, increase the effect of weight loss ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] Implementation Example 1

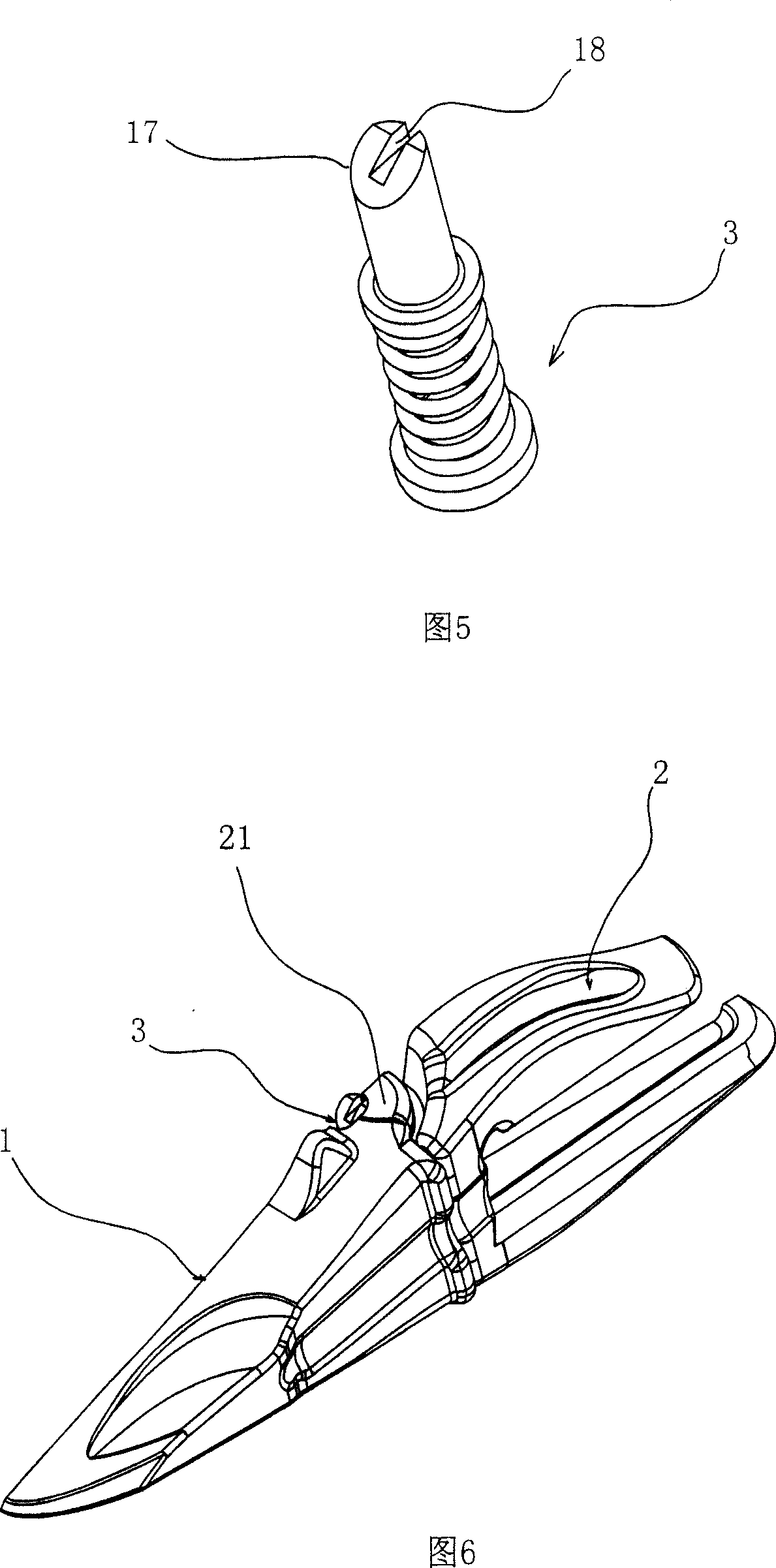

[0038]As shown in Figure 3-12, a connection structure between a bucket tooth and a tooth holder, which includes a bucket tooth 1, a tooth holder 2 and a pin 12, wherein the tooth holder 2 includes a front tooth holder head 9 and a rear part The tooth seat connection part 8 of the tooth seat is like the tooth seat open gear, the front tooth seat head 9 is used to connect the front end of the bucket tooth 1, and the rear tooth seat connection part 8 is used to fix the tooth seat 2 to the bucket of the engineering vehicle bucket On the board, see Figure 3. The bucket tooth 1 is composed of the tooth tip 4 and the bucket tooth cavity 5. The bucket tooth cavity 5 includes the bucket tooth inner cavity 6 and the bucket tooth outer cavity 7. See Figures 9 and 10. The cavity 6 accommodates the tooth seat head 9, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com