Non-process sealing circulation technology for wastewater from pulp and paper making by non-delignify reaction

A pulp and paper making, closed-cycle technology, applied in the field of clean production technology, can solve problems such as lack of enthusiasm, increase in equipment investment and production costs of pulp and paper making enterprises, and difficulty in handling papermaking sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

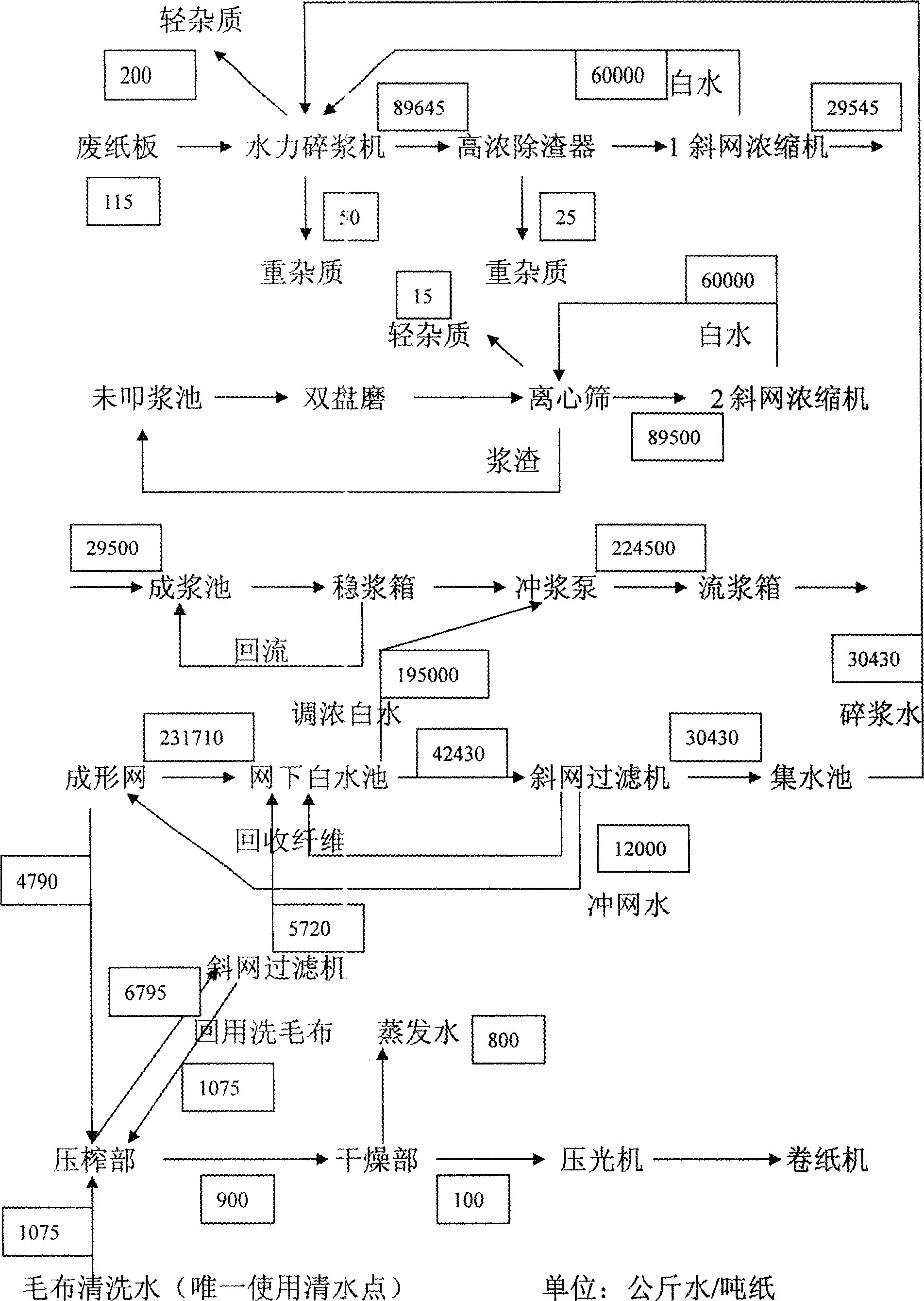

[0009] The untreated closed cycle technology of pulping and papermaking wastewater without delignification reaction of the present invention will be further described below in conjunction with the accompanying drawings. In the waste paper production and packaging cardboard pulping and papermaking process shown in the attached figure, the wastewater in the pulping section mainly includes the waste paper shredding water and screening dilution water of the hydropulper. The waste paper shredding water of the hydropulper uses all the filtered white water under the 1 inclined screen thickener and the excess white water under the screen in the sump of the papermaking section; all the screened dilution water uses the filtered white water under the 2 inclined screen thickener. The water used in the papermaking section is mainly the concentration and dilution water of the online slurry, the flushing water of the forming screen of the paper machine, and the felt cleaning water in the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com