Product line for alpha rice

A production line, α-rice technology, applied in application, food preparation, food science and other directions, can solve the problems that the quality is not easy to reach a unified standard, affect the quality and output, and the labor intensity of workers is high, so as to shorten the drying time. , improve hygiene standards, reduce the effect of manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

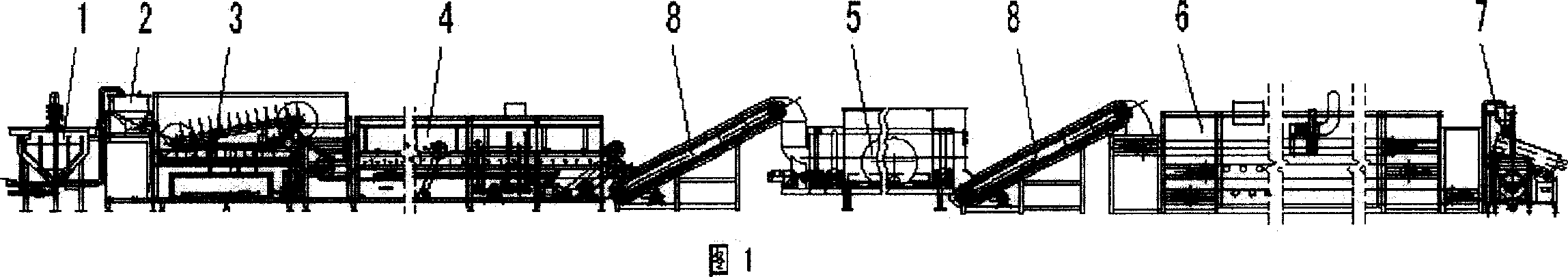

[0027] Example. The overall structure of the alpha rice production line is shown in Figure 1. The composition of the production line includes a rice washing machine 1, a drainer 2, a soaking tank 3, a rice steaming box 4, a centrifugal dryer 5, a drying box 6 and a granulator 7 They are sequentially connected in series, and lifting devices 8 are respectively provided at both ends of the centrifugal dryer 5 .

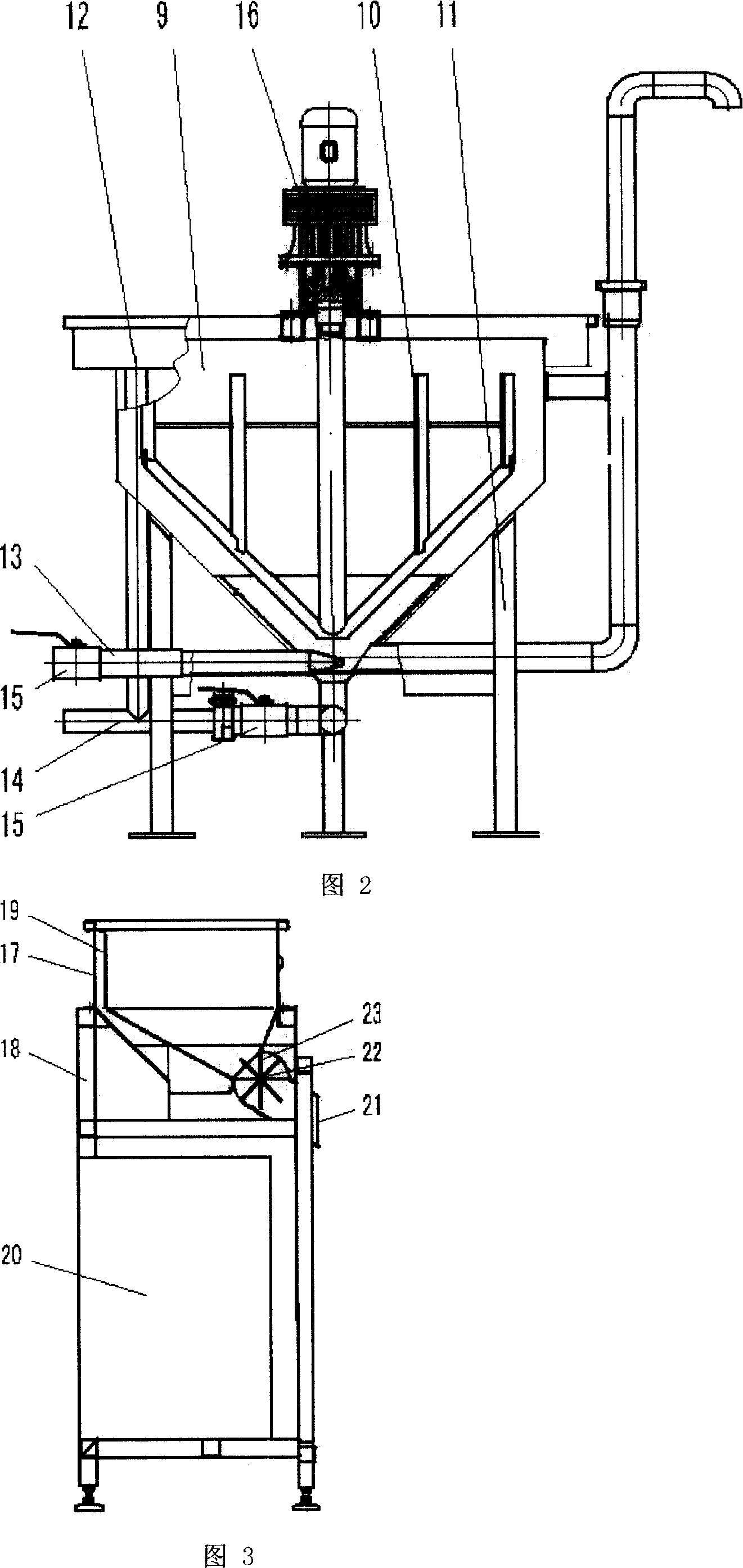

[0028]The rice washing machine in the alpha rice production line is shown in Figure 2. The rice washing machine 1 includes a funnel-shaped rice washing cylinder 9 and paddle leaves 10. The rice washing cylinder 9 is fixed on the rice washing machine frame 11. An overflow hole 12 is provided on the upper part of the rice washing cylinder 9. , the bottom of the rice washing cylinder 9 is connected with the high-pressure water pipe 13 and the drain pipe 14, the high-pressure water pipe 13 and the drain pipe 14 are respectively provided with a valve 15, and the reduction mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com