Plasm restraint device

A plasma and confinement device technology, applied in the field of substrate devices, can solve problems such as processing chamber pollution, achieve the effects of preventing pollution, improving utilization, and preventing secondary discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

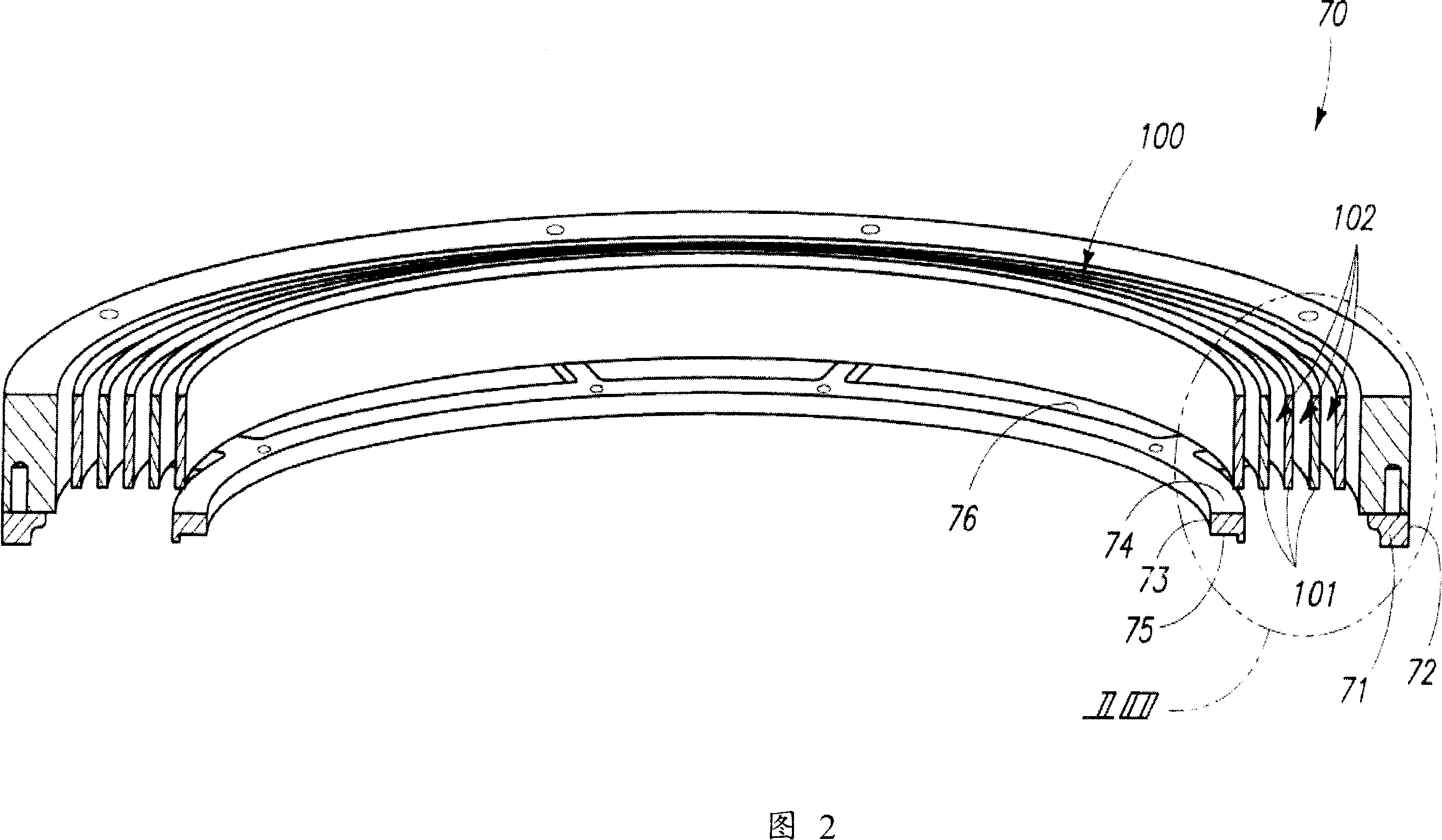

[0051] As another embodiment of the present invention, the conductive element 100 may also be formed of a conductive semiconductor material doped with impurities, wherein the impurities are various elements or various elements that can make the semiconductor material conductive In combination, preferably, in this embodiment, the conductive element 100 is formed of a silicon semiconductor material doped with boron or nitrogen.

[0052] In the embodiment shown in FIG. 2 and FIG. 3 , the conductive element 100 is formed by a plurality of conductive concentric rings 101 and a conductive support ring 90 , and channels 102 are formed between the conductive concentric rings 101 . As a modification of this embodiment, the conductive element 100 can be an integrally formed conductive plate (not shown), which is arranged around the lower electrode in a substantially ring shape, and is arranged in the processing area and the plasma processing apparatus. Between the exhaust areas, through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com