Intelligent spiral bevel gear assembled milling cutter disc measuring and regulating instrument

A spiral bevel gear assembly technology, which is applied in the field of intelligent spiral bevel gear assembly milling cutter disc measurement and adjustment instrument, can solve the problems of long distance adjustment position, complicated adjustment process, and low measurement accuracy, so as to improve the accuracy and efficiency, the overall structure is simple, and the effect of broad market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The composition of the present invention will be described in detail through specific embodiments below in conjunction with the accompanying drawings; however, the description of the embodiments of the present invention is illustrative rather than restrictive, and the scope of protection is subject to the content of the claims.

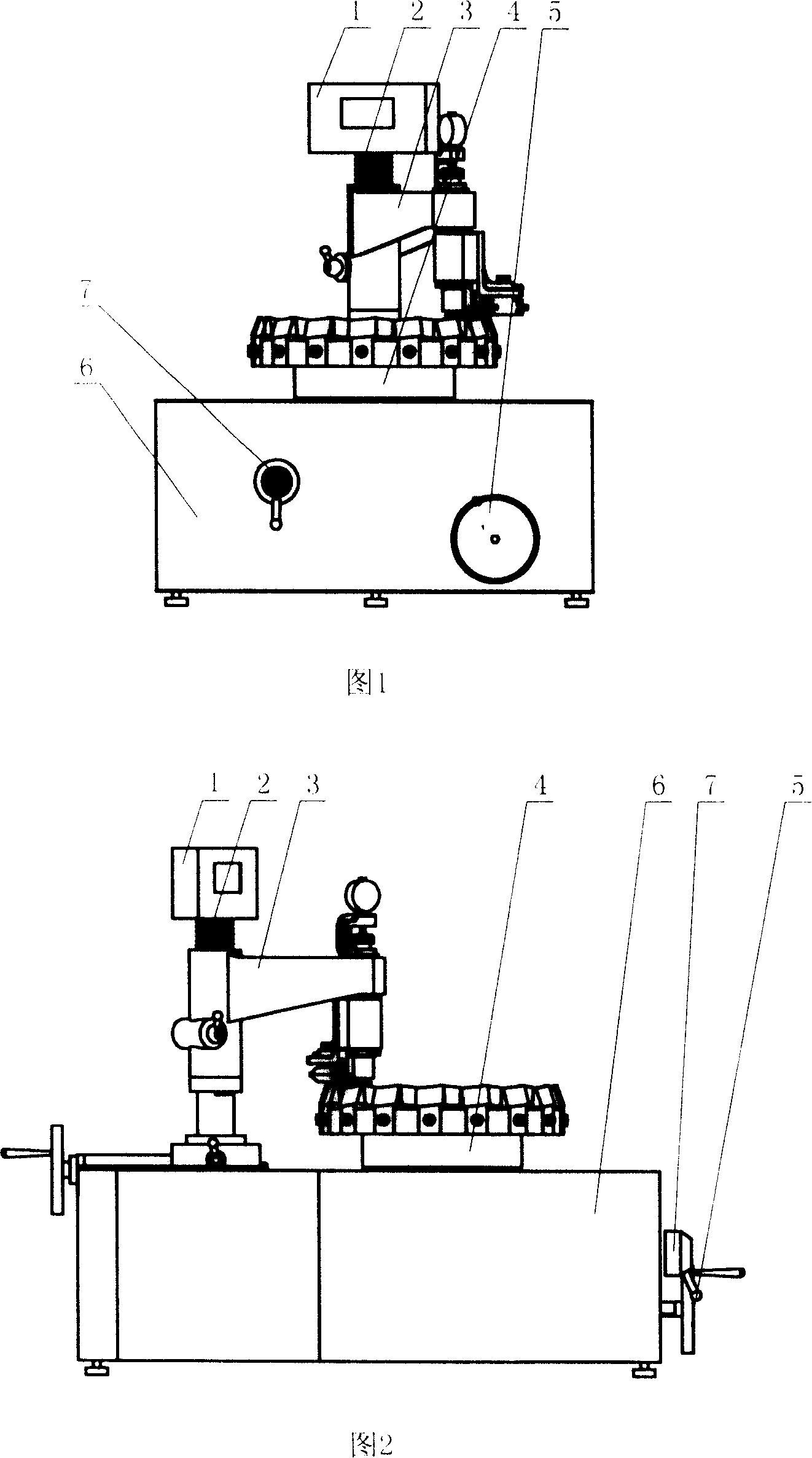

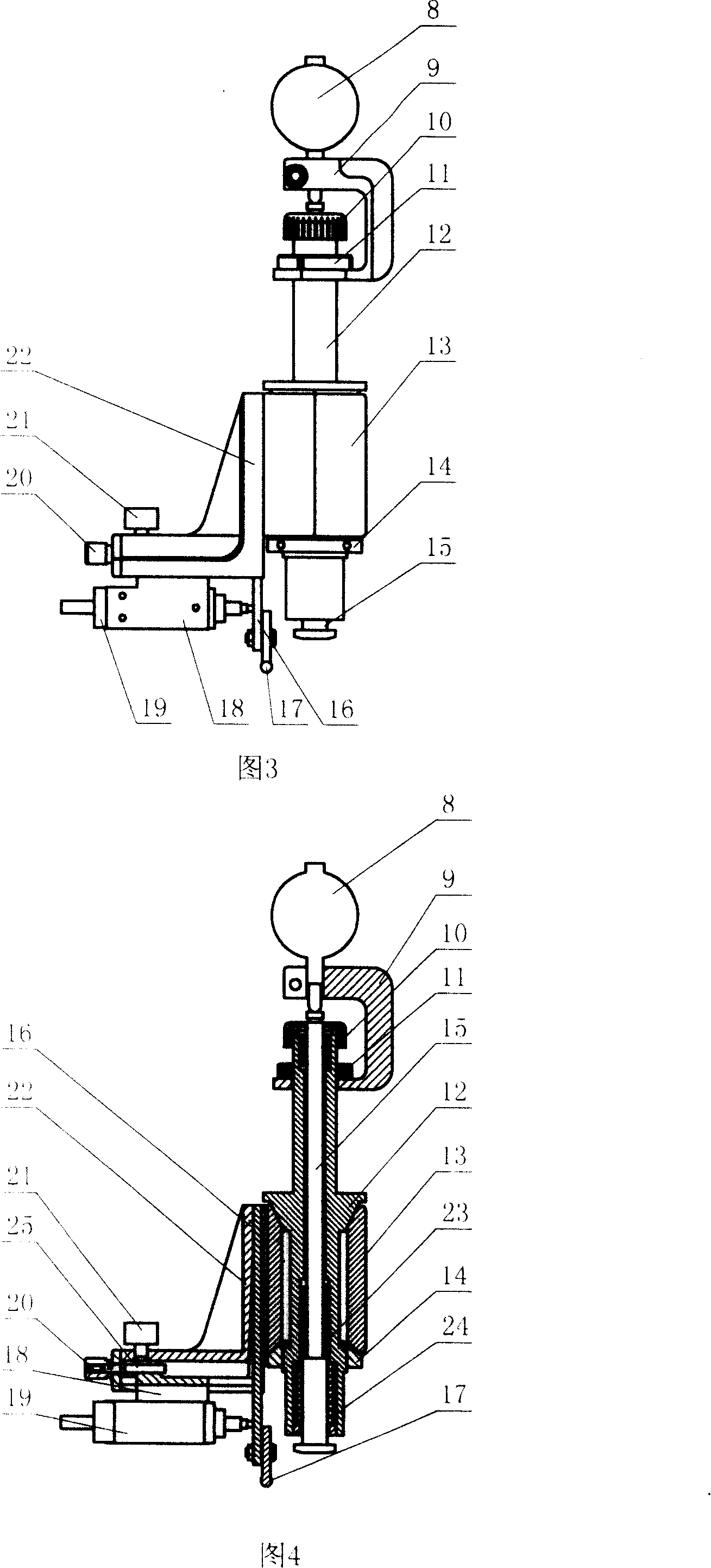

[0025] This intelligent spiral bevel gear assembled milling cutter head measuring and adjusting instrument has its main body (see Figure 1 and Figure 2) consisting of a machine base 6, a cutter head spindle 4, a column 2, a horizontal swing arm 3, a multimeter display box 1 and It consists of an integrated measuring head, in which the spindle of the cutter head and the column are respectively installed on the workbench of the machine base, and the clutch operating handle 7 and the hand wheel 5 are also installed on the machine base. The indicator box is installed on the top of the column, and the horizontal swing arm The front end of the integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com