Magnetic lag synchronous motor and its making technology

A synchronous motor and hysteresis technology, applied in the direction of synchronous motors for single-phase current, manufacturing motor generators, electric components, etc., can solve problems such as difficult processing, high noise, complex winding structure, etc., without damaging internal components Devices, improved work efficiency, novel structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

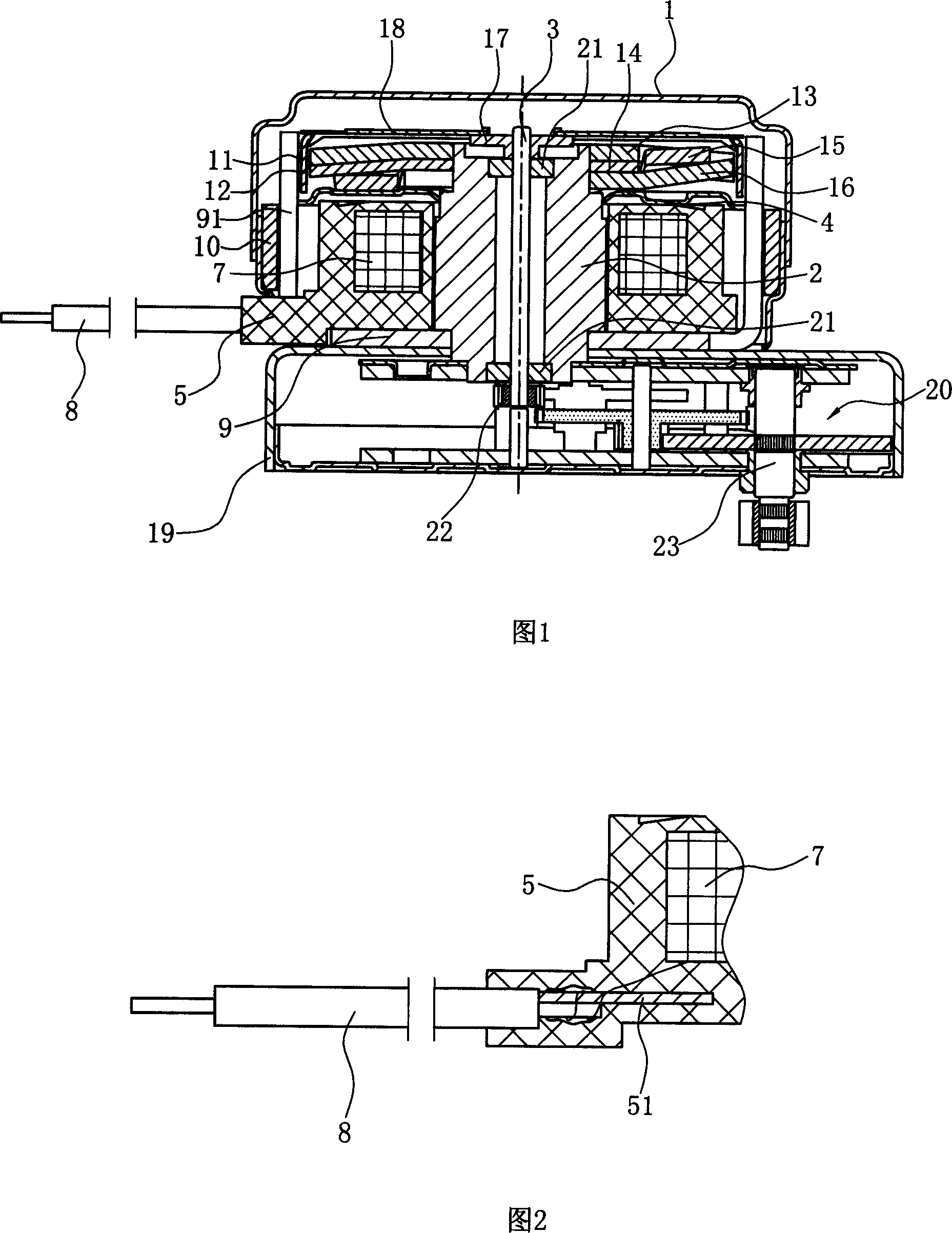

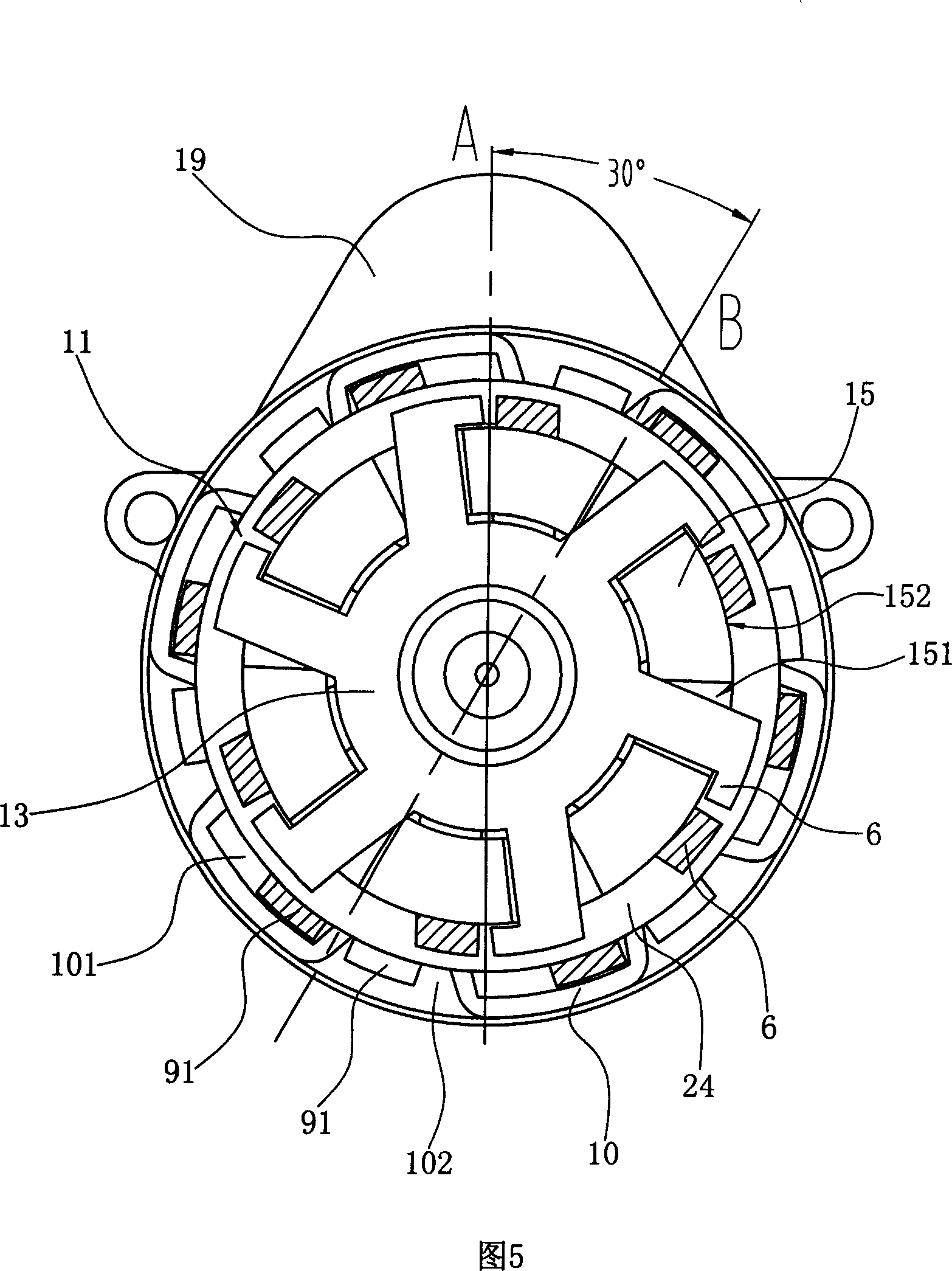

[0025] As shown in Figures 1 to 6, a hysteresis synchronous motor includes a casing 1, the bottom of the casing 1 is fixed with a gearbox frame 19, and a gearbox assembly 20 is arranged in the gearbox frame 19, and the gearbox assembly 20. The gearbox assembly in the existing motor can be used. The gearbox assembly is a gear transmission mechanism, which is a conventional technology, so no detailed description is given;

[0026] The casing 1 is provided with an axially hollow iron core 2, and the iron core 2 is made of electric pure iron rods. Pass through the lower part of the casing 1 and enter into the gearbox frame 19, and connect with the gearbox assembly 20 through the head wheel 22 arranged on the rotating shaft 3;

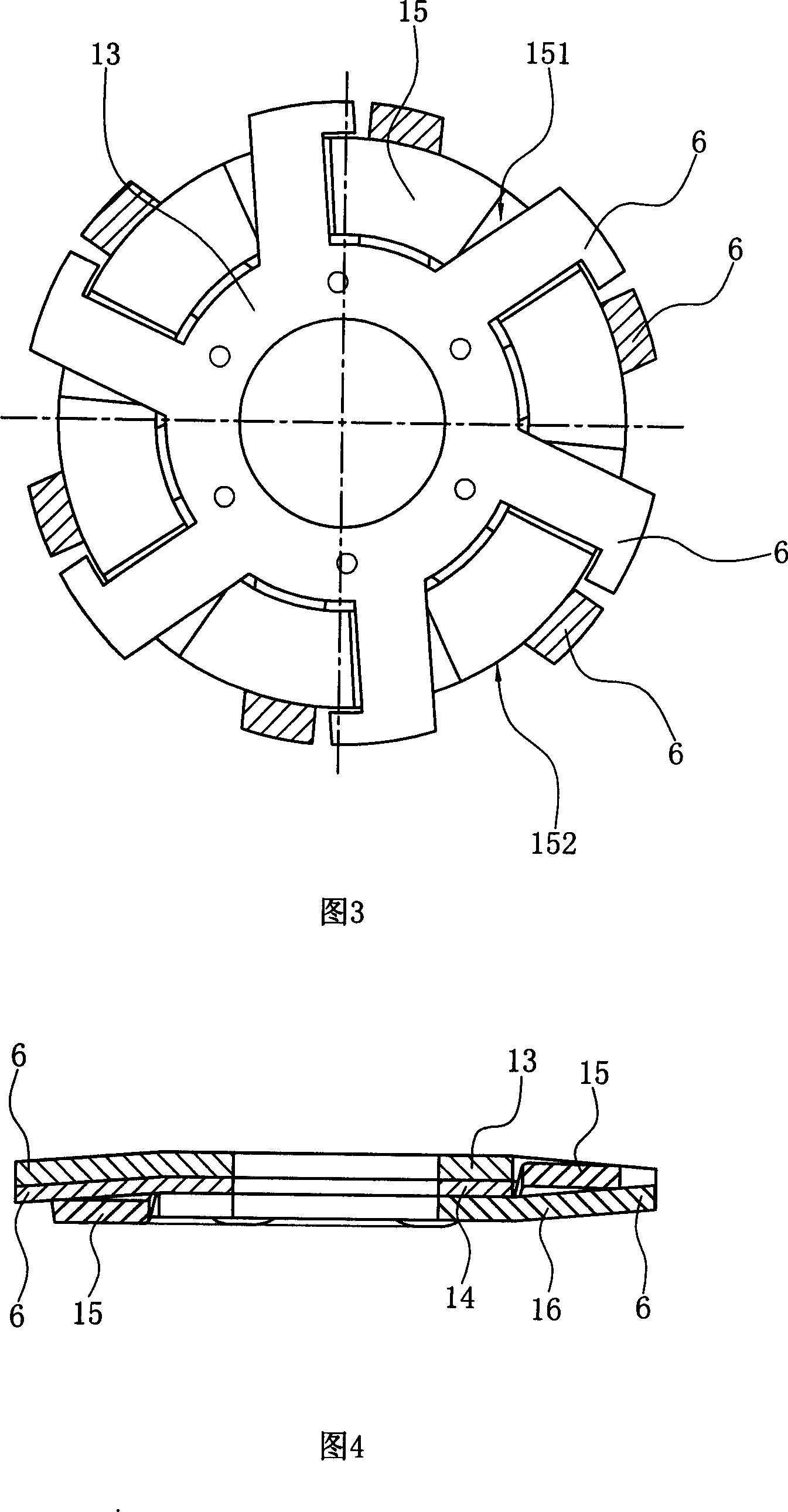

[0027] As shown in Figures 3 and 4, the lower stator claw pole assembly is sleeved and fixed on the upper part of the iro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap