A control system and control method for fuel battery

A fuel cell and control system technology, applied in the direction of fuel cell control, fuel cell, fuel cell additives, etc., can solve the problems of implementing complex functions and increasing the cost of PEM fuel cell controllers, and achieve cost reduction, simplified structure and control Algorithms, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

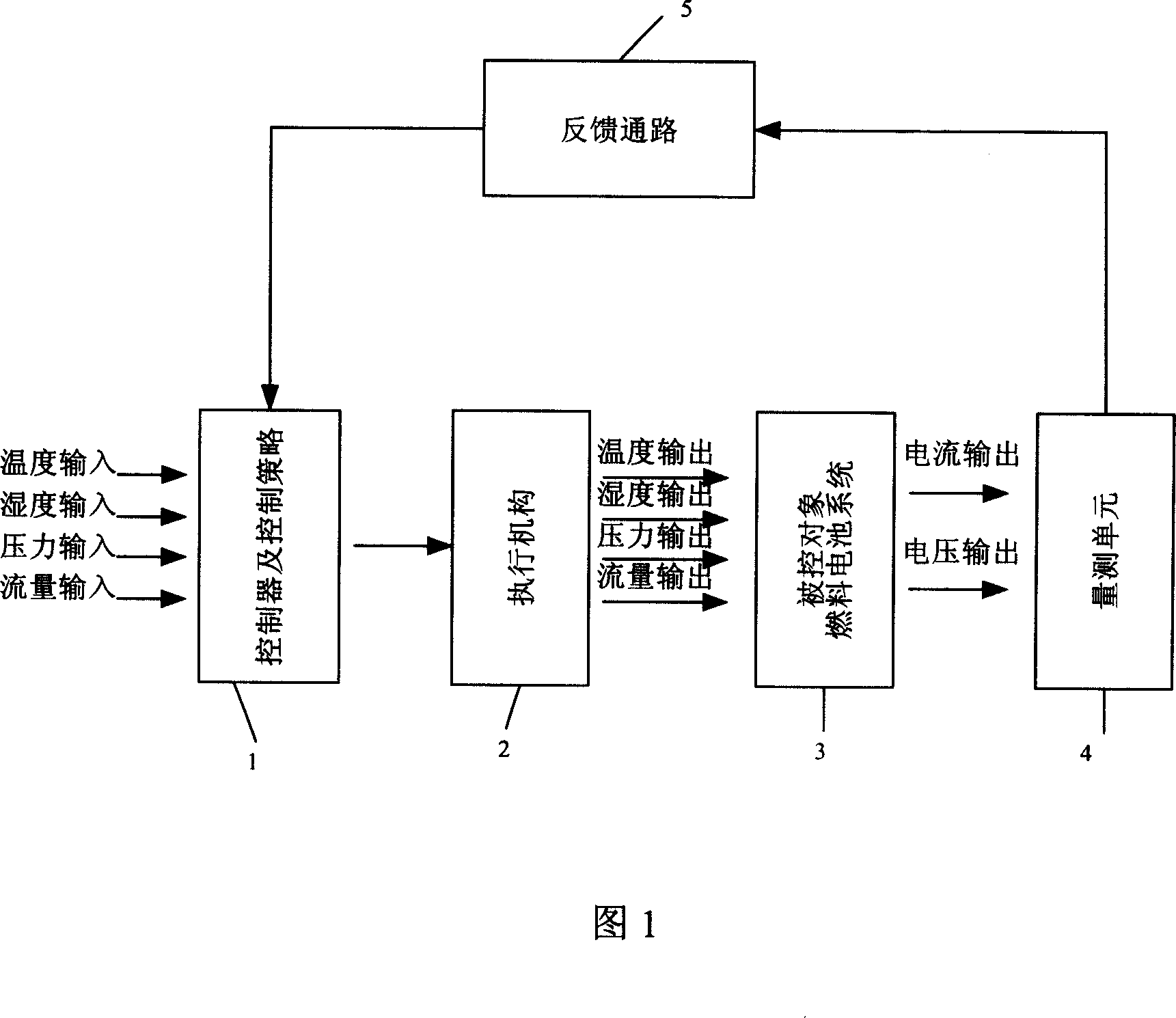

Image

Examples

specific Embodiment 1

[0034] Specific Embodiment 1. Based on the above-mentioned research results, the control system of this embodiment is shown in Figure 2. It includes a fuel cell control unit 101 composed of a microprocessor, a storage unit 102 for storing operating parameters, and a temperature control implementation Mechanism 103, humidity control actuator 104, pressure control actuator 105, flow control actuator 106, measurement unit 108 and power adjustment unit. When the fuel cell is inspected as a finished product, the output characteristics of the fuel cell are divided into several continuous power intervals, and each power interval (that is, the maximum value and minimum value of the interval power) and the preferred power corresponding to the power interval The power point and the setting values of a series of main working parameters of the control system corresponding to the preferred power point are stored in the storage unit of the control system. Usually, the working parameters in...

specific Embodiment 2

[0057] The second embodiment is different from the first embodiment in that the power adjustment unit can also be realized through the solution shown in FIG. 5 .

[0058] The power conditioning unit includes an additional load 209 and an additional load management module 210 , and the additional load 209 is connected in series in the loop composed of the fuel cell 107 and the load 111 to play a role of power consumption. The control unit 101 compares the set optimal power point value with the system load power, and outputs a control signal to the additional load management module 210, so that the additional load management module 210 controls the additional load 209 to reduce the power when the power required by the load is greater than the optimal power point. Consumption, when the power required by the load is less than the preferred power point, control the additional load 209 to increase power consumption, so that the fuel cell 107 works at the set preferred power point.

...

Embodiment 2

[0064] Embodiment 2 further reduces the cost of the fuel cell control system while sacrificing a certain fuel cell power generation efficiency but ensuring the stable operation of the fuel cell.

[0065] The specific embodiment above describes a composition method of a proton exchange membrane fuel cell control system that includes data storage units segmented according to the power level. In actual use, because the size of the fuel cell discharge power can also be characterized by the size of the fuel cell discharge current or the size of the discharge voltage or the impedance of the fuel cell, the present invention can also be characterized by the size of the current, the size of the voltage or the size of the impedance. Carry out segmentation, monitor the corresponding electrical characteristics of the load, and build a segmented fuel cell control system that stabilizes the fuel cell at a certain discharge current point, discharge voltage point, or impedance point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com