Spring type safety self-destruction syringe

A spring type, syringe technology, applied in the direction of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of complex structure and assembly process, and achieve the effect of novel structure and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, referring to Fig. 1-Fig. 2, a spring safety self-destructing syringe, including a needle cover 1, a steel needle 2, a needle seat 3, a syringe 10 and a core rod 11 located in the syringe, the upper part of the needle seat A steel needle 2 is installed, and a glue filling cavity 22 is set on the upper end of the needle seat, which is used for fixing and sealing the steel needle after sizing. A washer 4 is arranged between the inner walls, and the washer 4 is elastically tightly fitted with the peripheral wall of the convex ring and the inner wall of the injection cylinder to form a non-return device for the needle seat; the core rod 11 is a hollow cylindrical structure, and a spring is arranged inside the core rod. A rubber plug 7 is arranged on the upper end, a bottom plug 12 is arranged at the lower end, a diameter-reducing pipe section 25 is arranged on the upper part, and an end plug 9 is arranged on the reducing-diameter pipe section. There is a convex...

Embodiment 2

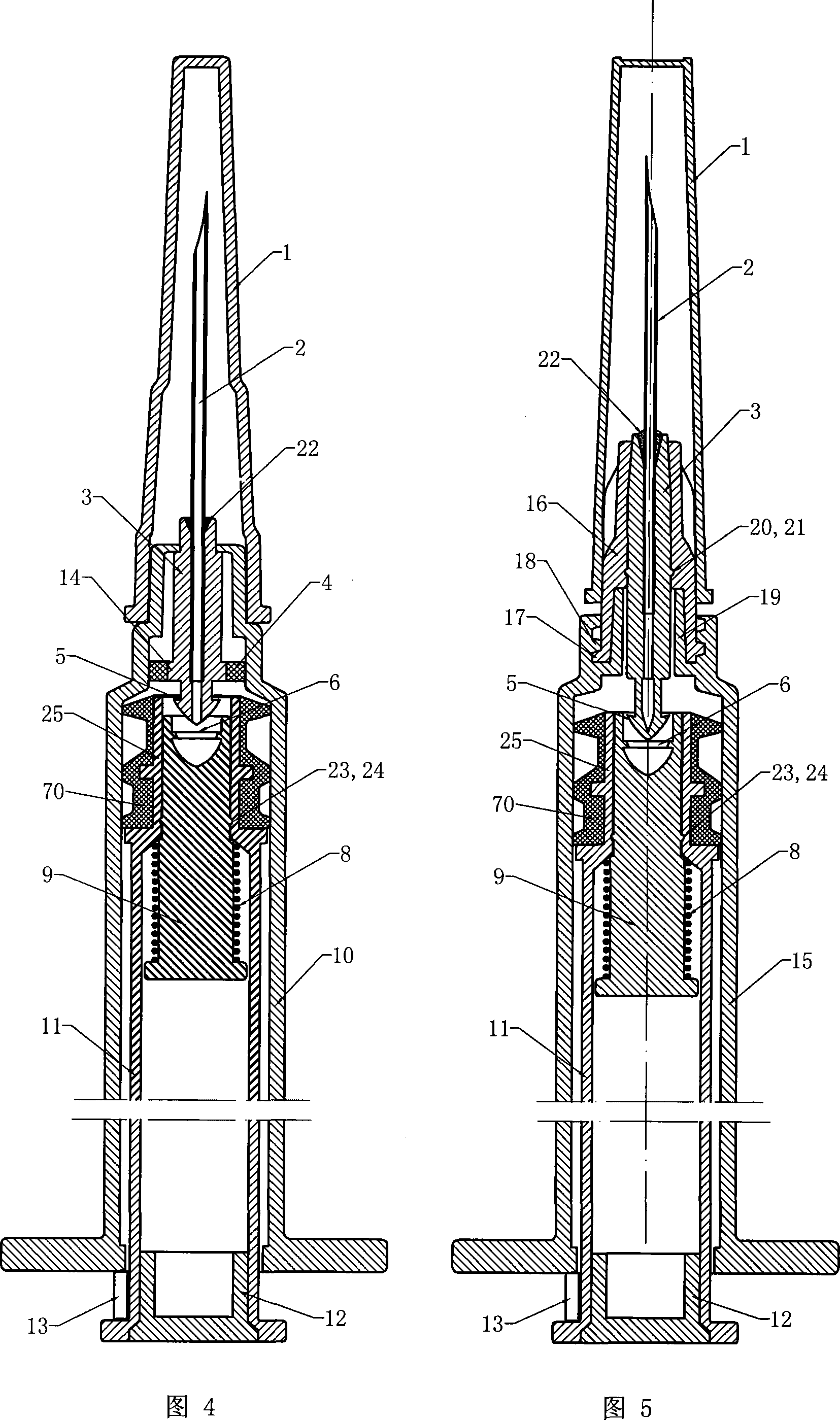

[0021] Embodiment 2, with reference to Fig. 3-Fig. 4, this spring safety self-destruction syringe compares with embodiment 1, and its difference is to adopt the elastic rubber stopper as shown in Fig. 3, and elastic rubber stopper comprises lower ring 71, middle ring 72 and The upper ring 73, the lower ring and the middle ring are connected in one piece, and the upper ring is connected with the middle ring through an elastic compression ring 75, and a groove 74 is provided on the shaft hole of the elastic rubber plug. The rest of the structure and working principle are the same as in Embodiment 1.

Embodiment 3

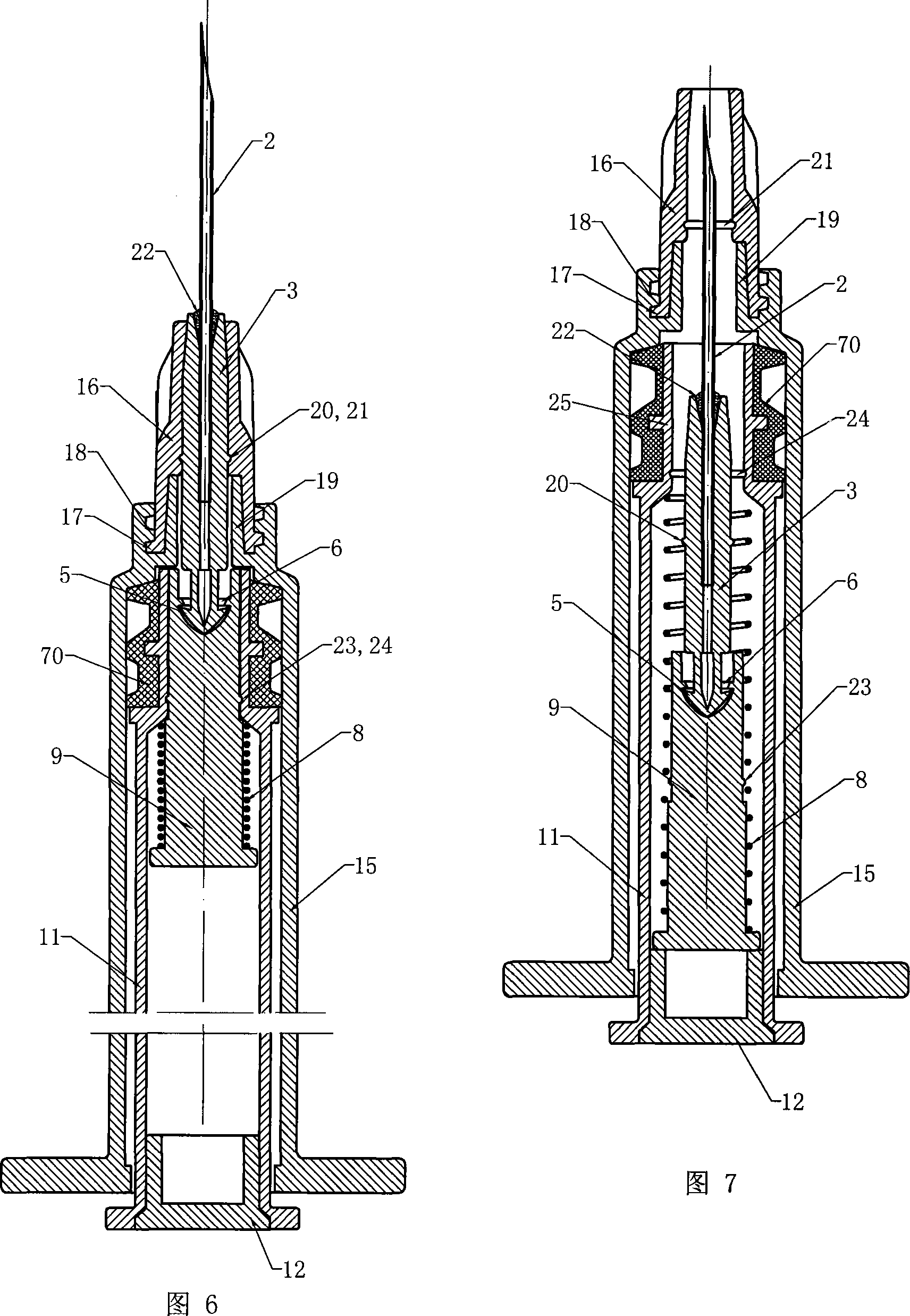

[0022] Embodiment 3, referring to Fig. 5-Fig. 7, the difference between this spring safety self-destructing syringe and Embodiment 2 is that: (a) the injection cylinder adopts a combined structure, and the cylinder body 15 and the outer needle seat 16 are connected by threads Composition, the external thread 17 is provided at the bottom of the outer needle seat, the sleeve 19 and the interlayer thread 18 are provided at the top of the cylinder body, the cylinder body 15 is connected with the outer needle seat 16 through threads; (b) the needle seat non-return device is arranged on the needle The snap ring 20 on the outer peripheral wall of the seat 3 and the snap groove 21 arranged on the inner peripheral wall of the outer needle seat 16 are formed, which can not only prevent the inner needle seat from retracting, ensure the smooth progress of the injection work, but also play a sealing role , which has the advantage of being conducive to mechanized and automated assembly line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com