Painting equipment with air purifying means

A technology for spraying equipment and air, which is applied in spray booths, injection devices, air quality improvement, etc., and can solve problems such as unwanted emissions of VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

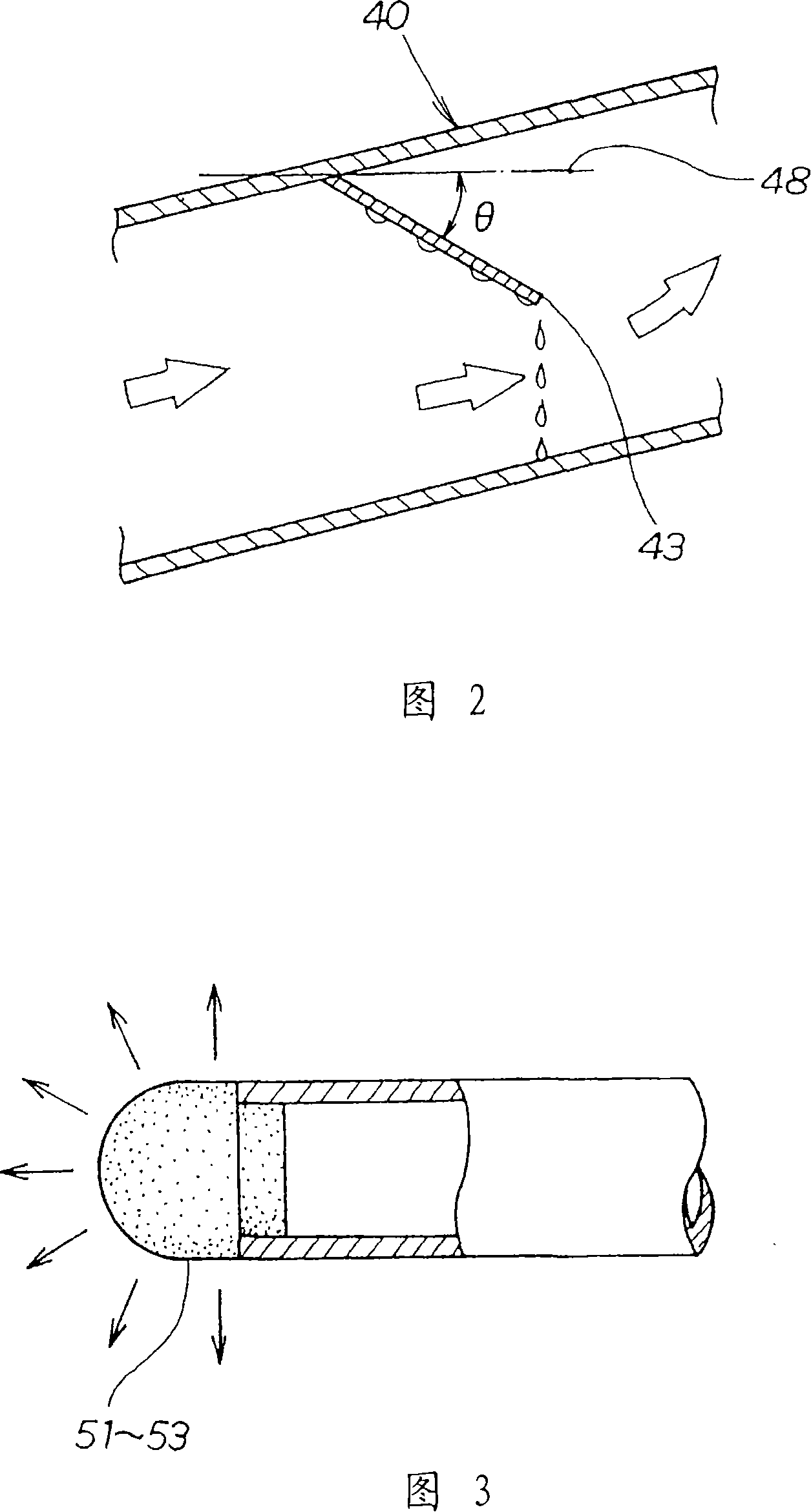

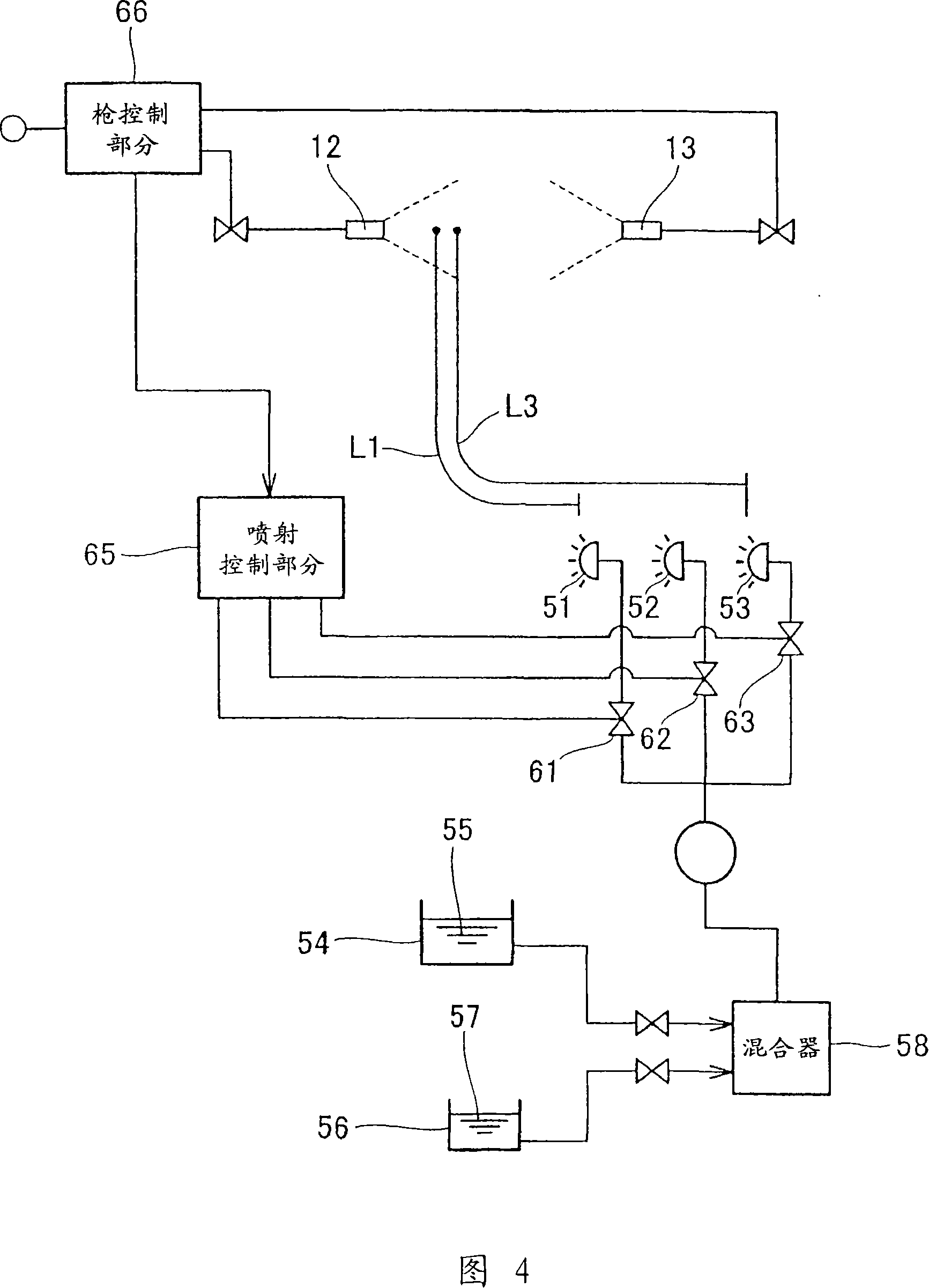

[0019] Fig. 1 is a view explaining the basic principle of the painting equipment according to the present invention. The painting apparatus 10 includes a pipe-shaped painting booth 14 that seals an object 11 to be painted, such as a vehicle body, and painting guns 12 and 13 that spray paint mist. Air is blown into the paint spray booth 14 from above the paint spray booth 14, so that paint residues floating in the paint spray booth 14 descend together with the blown air. The painting apparatus 10 also includes a water washing device 30 provided at a lower end portion of the painting booth 14 for washing blown air. The water-washed air is guided from the lower end of the spray booth 14 to a discharge pipe 40 through which the water-washed air is discharged out of the painting installation 10 through a muffler 42 having a built-in filter 41 . In the discharge pipe 40, the painting apparatus 10 further includes adsorbent nozzles 51-53 for spraying a mixed liquid which is a mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com