Pneumatic vehicle tire

A technology for pneumatic tires and vehicles, used in heavy-duty tires, heavy-duty vehicles, special tires, etc., to solve the problems of decoupling groove cracks, enlarged belts, groove cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

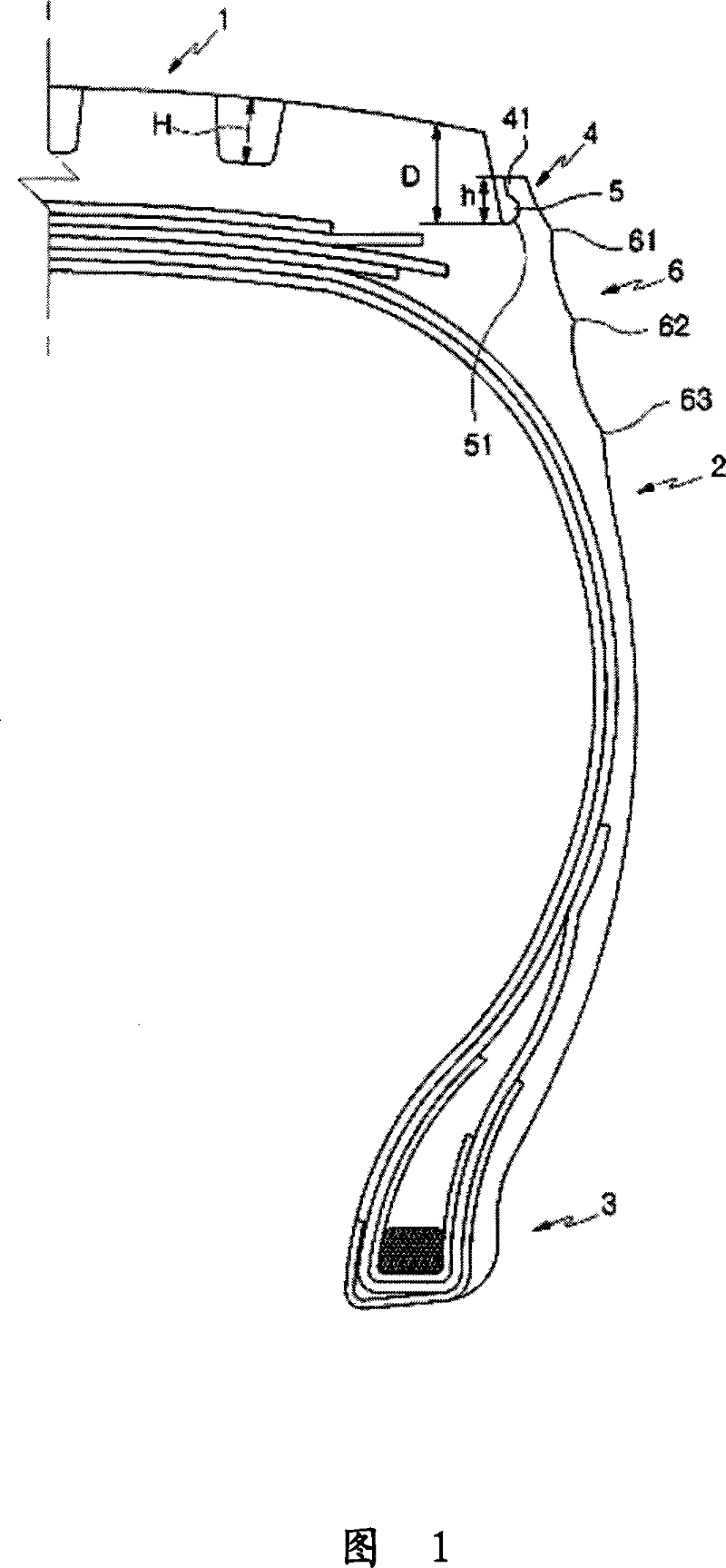

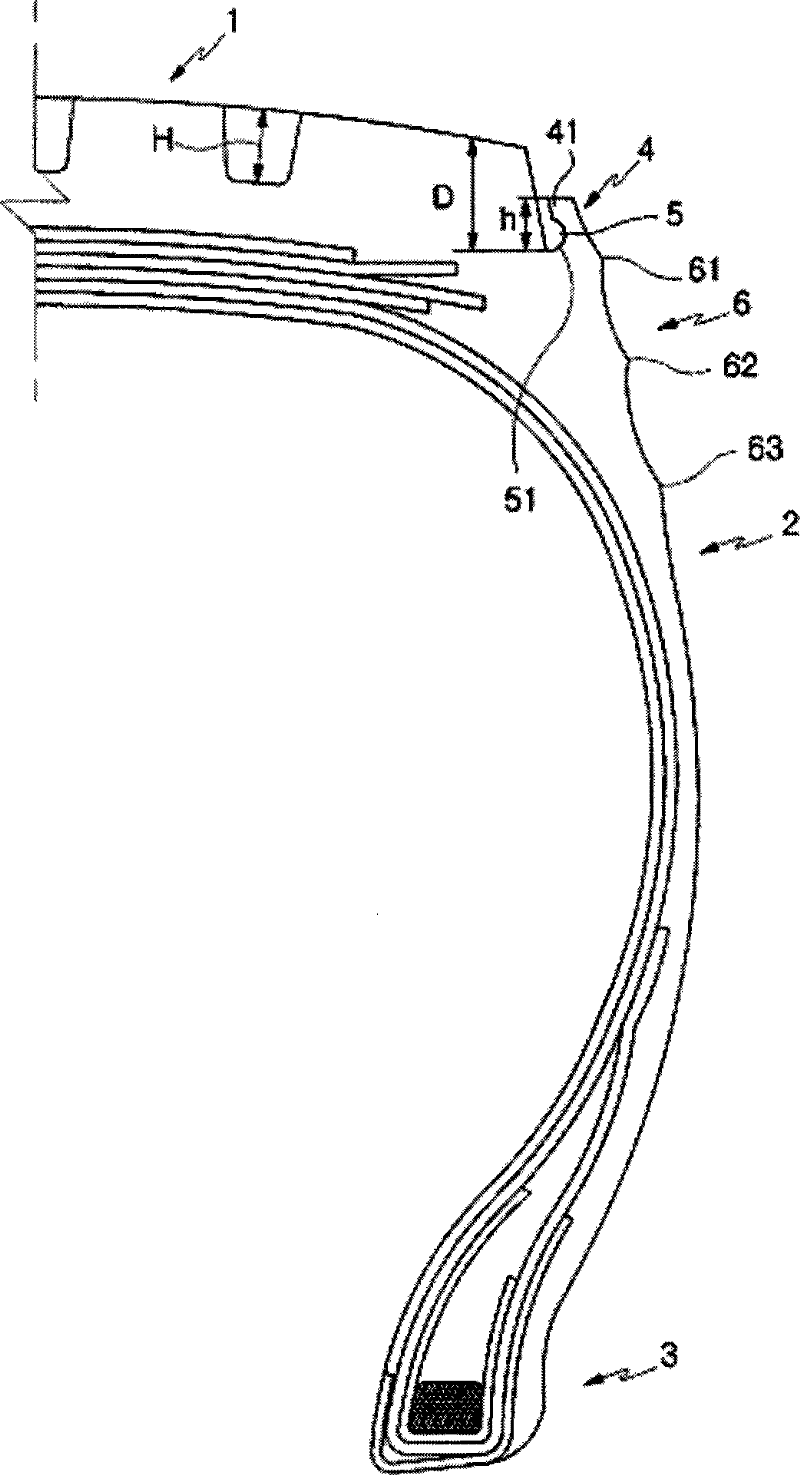

[0009] The present invention, in a pneumatic tire for a vehicle composed of a tread, a sidewall and a bead, is characterized in that an additional height (h) that is lower than the height (H) of the main rib is provided at both ends of the tread Rib 4, and the additional rib 4 is formed in a hook shape with a protrusion 41 on the inside, and the decoupling groove 5 formed by the additional rib 4 and the adjacent block has a narrow entrance width (s), the decoupling groove 5 The bottom is 51 wide.

[0010] Preferably, the height (h) of the additional rib 4 is 20%-50%, especially 38%, of the height (H) of the main rib. Preferably, the bottom 51 of the aforementioned decoupling groove 5 is formed into a circle with a vertical cross-sectional shape with a radius of curvature of R1.5. This shape disperses the stress and can prevent cracking. In order to have a better cushioning effect, preferably, the total depth (D) of the decoupling groove 5 from the tread surface is 100-110% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com