Pneumatic vehicle tire

A technology for pneumatic tires and vehicles, used in heavy-duty tires, heavy-duty vehicles, special tires, etc., and can solve problems such as cracked belts, groove cracks, and decoupling groove cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

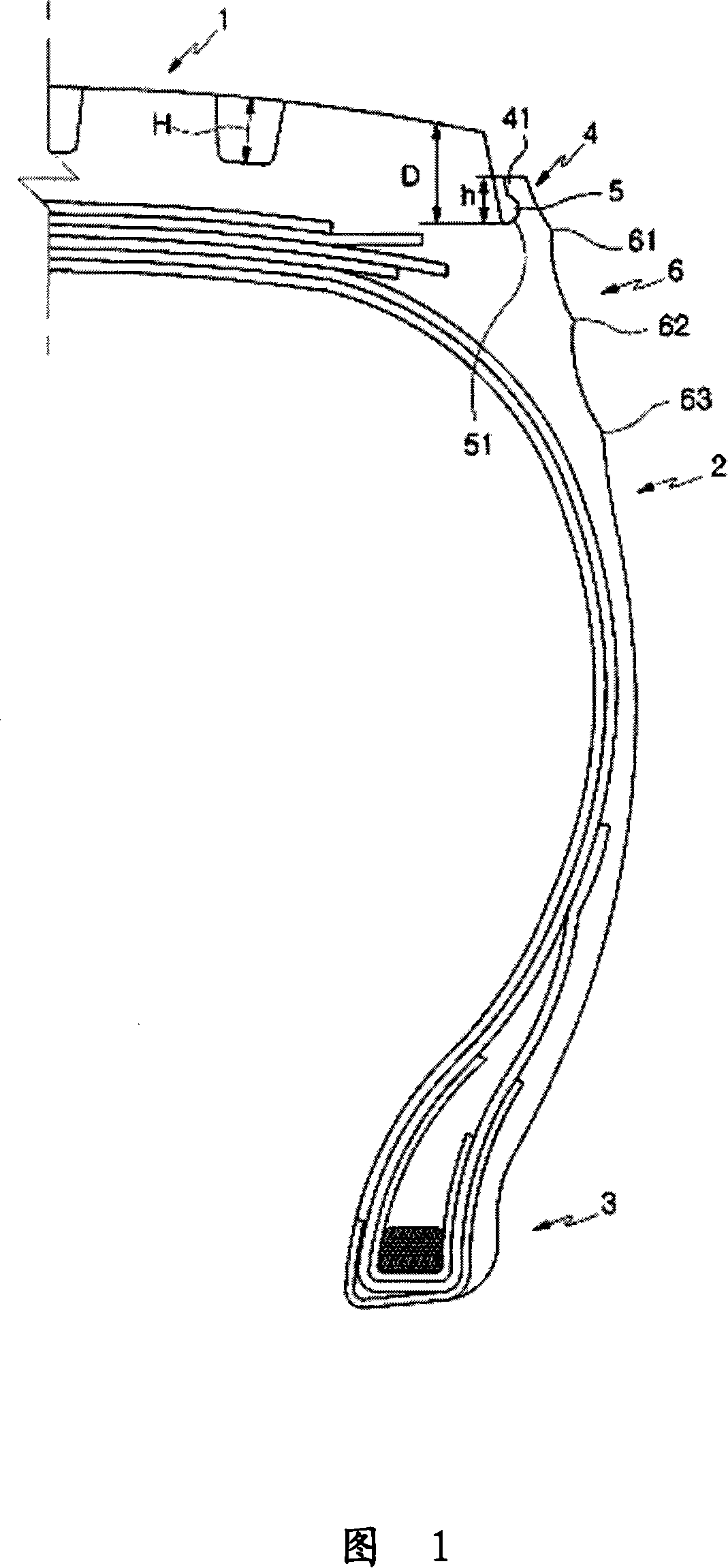

[0009] The present invention is a pneumatic tire for vehicles composed of a tread, a sidewall, and a bead, wherein additional ribs having a height (h) lower than the height (H) of the main rib are provided at both ends of the tread. rib 4, and the additional rib 4 is formed in a hook shape with a protrusion 41 inside, and the entrance width (s) of the decoupling groove 5 formed by the additional rib 4 and the adjacent block is narrow, and the decoupling groove 5 is narrow. The bottom is 51 wide.

[0010] Preferably, the height (h) of the additional ribs 4 is 20%-50%, especially 38%, of the height (H) of the main ribs. Preferably, the bottom 51 of the above-mentioned decoupling groove 5 is formed into a circle whose vertical cross-sectional shape has a radius of curvature of R1.5, and this shape can disperse stress, thereby preventing cracking. In order to have a better cushioning effect, preferably, the total depth (D) of the decoupling groove 5 from the tread is 100-110% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com