Manufacturing equipment for rubber belts

A technology for manufacturing devices and rubber belts, used in flat products, other household appliances, shafts and bearings, etc., can solve problems such as cracks in the outer layer, and achieve the effect of suppressing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

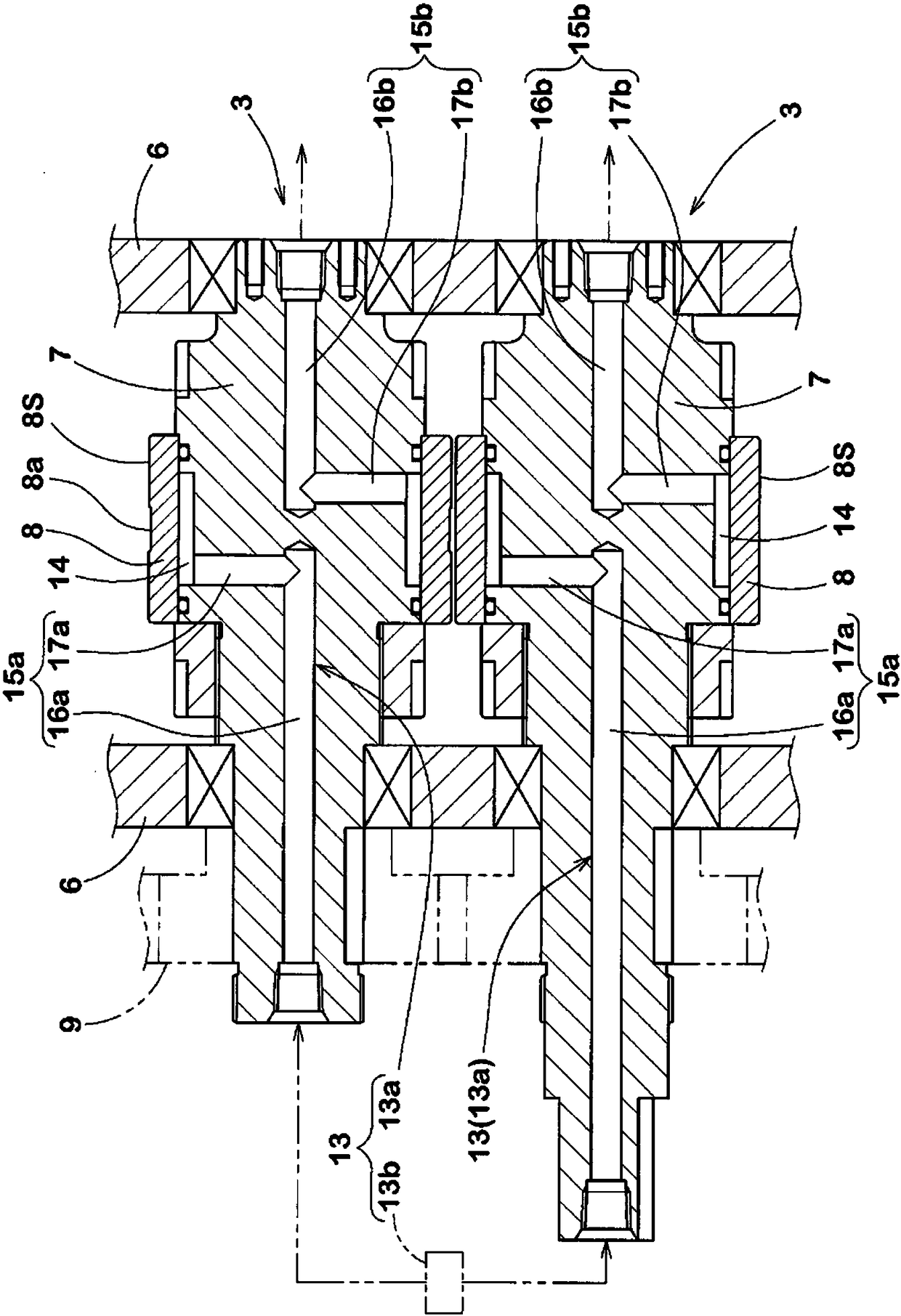

[0017] Hereinafter, an embodiment of the present invention will be described based on the drawings.

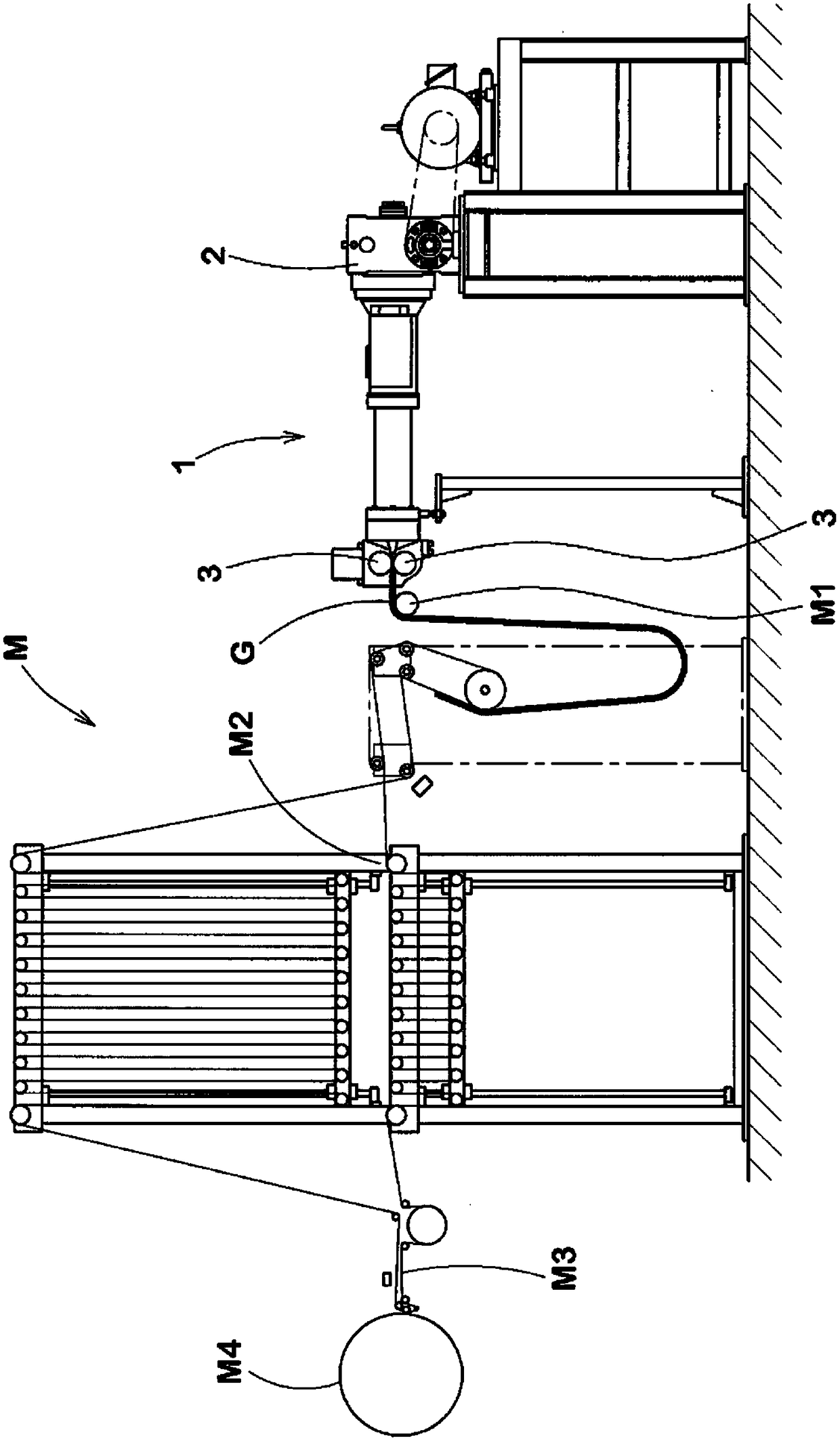

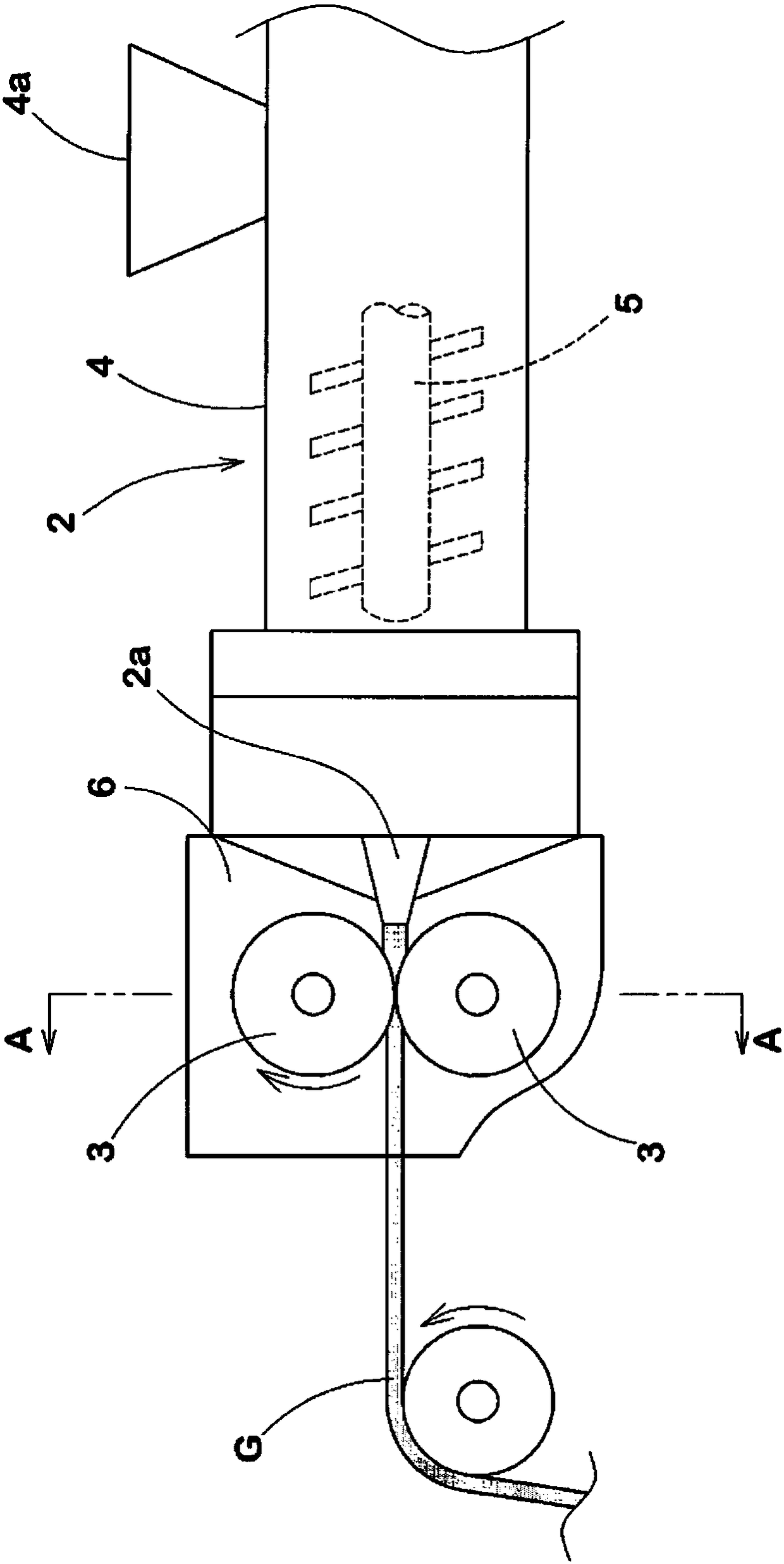

[0018] exist figure 1 The side view of the manufacturing apparatus (it may just describe as "manufacturing apparatus" hereafter) 1 of the rubber belt of this embodiment is shown in . Such as figure 1 As shown, the manufacturing apparatus 1 is provided with a rubber extruder 2 for continuously discharging rubber, and a pair of upper and lower calender rolls 3, 3 for rolling the rubber discharged from the rubber extruder 2 to form a rubber belt G.

[0019] The manufacturing apparatus 1 of this embodiment is suitably used for the raw tire manufacturing apparatus M which molds the rubber belt G used for manufacturing a tire, for example. The green tire manufacturing apparatus M is provided with, for example, a pick-up roll M1 that picks up the rubber belt G from the calender roll 3, a storage unit M2 that temporarily stores the rubber belt G on the downstream side of the pick-up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com