Compound thermal insulation wall plate and external wall heat-insulation board producing line

A technology for external wall thermal insulation and composite thermal insulation, which is applied in ceramic molding workshops, supply devices, unloading devices, etc., can solve the problems of unguaranteed quality and low construction efficiency, and achieve high production efficiency, high processing quality, and simple operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

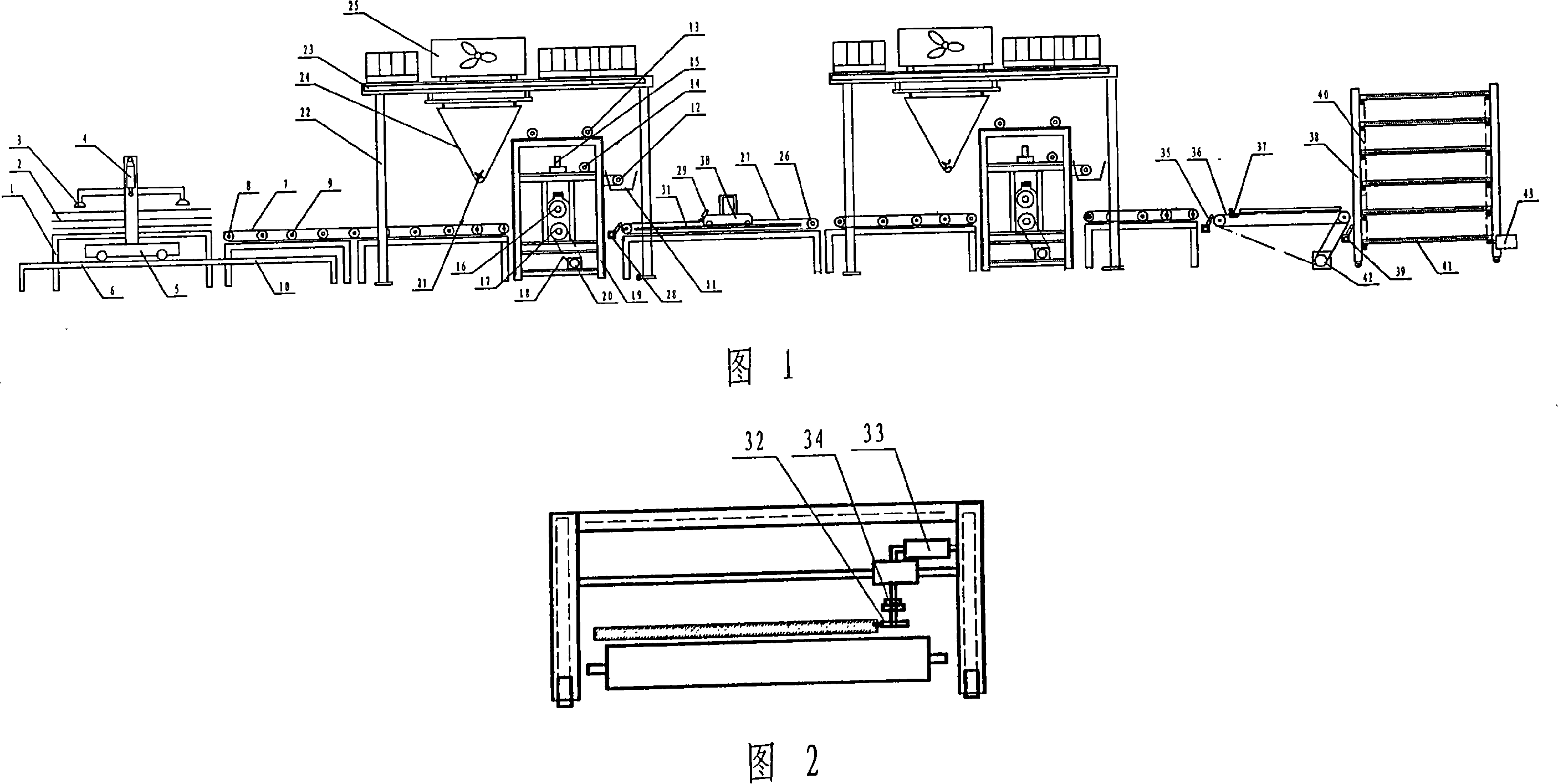

[0015] The present invention will be further described below in conjunction with the accompanying drawings:

[0016] As shown in Figure 1, the belt conveyor line includes a conveyor line workbench 10, a conveyor belt 7, a transmission roller 8 and a conveyor roller 9. The conveyor belt 7 is installed on the conveyor line workbench 10, and the transmission roller 8 and the conveyor roller 9 are respectively It is sleeved at the end position and the middle position of the conveying belt 7. The belt conveying assembly line transmission roller 8 installed on the conveying line workbench 10 drives the conveying belt 7 to rotate, which in turn rotates the conveying idler roller 9 so as to convey the pallet 2 (and the plates on it) forward.

[0017] The automatic loading template mechanism includes a support template support at the front end of the belt conveyor line, a support template stacked on the support template support 1, a guide rail 6 located on both sides of the support templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com